Sep . 24, 2024 14:02 Back to list

Cost Analysis of HDPE Sheets for Various Applications and Industries

Understanding the Cost of HDPE Sheets Factors and Considerations

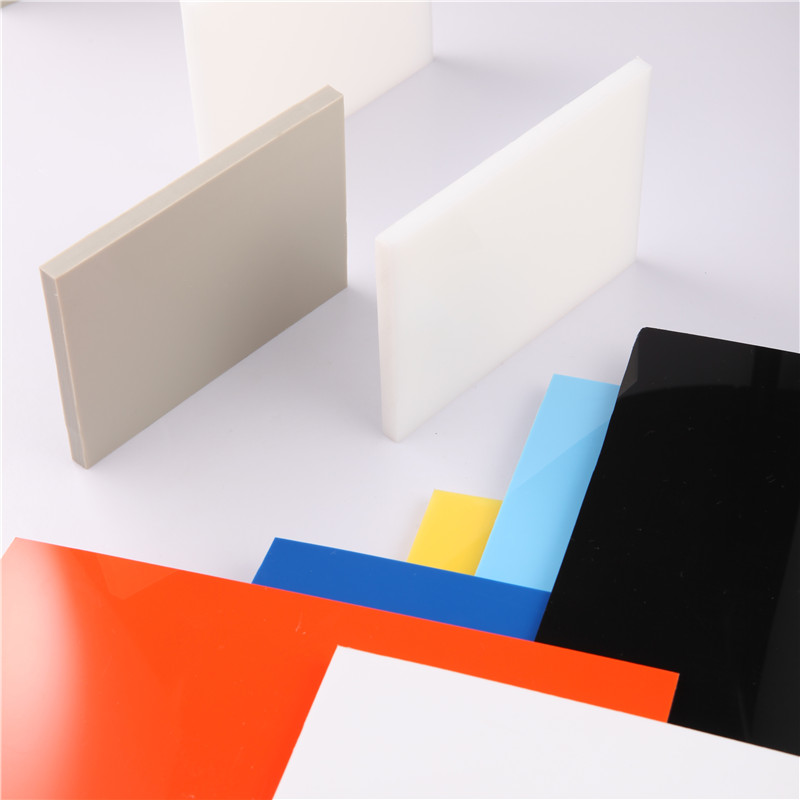

High-Density Polyethylene (HDPE) sheets are widely recognized for their versatility and durability. Used in various industries—from construction to packaging—HDPE sheets serve multiple purposes, including fabrication, storage, and even artistic endeavors. When it comes to purchasing HDPE sheets, understanding their cost is crucial for making informed decisions. In this article, we will explore the factors influencing HDPE sheet prices, helping you recognize what impacts the costs and how to budget effectively.

Material Quality and Thickness

One of the primary factors affecting the cost of HDPE sheets is material quality. HDPE comes in various grades, each tailored for specific applications. For instance, industrial-grade sheets might be less expensive due to their intended purpose, while food-grade sheets can be significantly pricier because they meet stringent safety regulations. Similarly, the thickness of the sheet contributes to the overall pricing. Standard thickness ranges from 0.1 inches to several inches, with thicker sheets generally commanding higher prices due to the increased material usage and enhanced durability.

Size and Dimensional Specifications

The size of the HDPE sheet also plays a significant role in determining its cost. Standard sheet sizes are often more affordable than custom-sized sheets due to economies of scale in manufacturing. Custom specifications may lead to additional cutting or processing fees, raising the overall expense. Therefore, if budget constraints are a concern, opting for standard dimensions might be a more economical choice.

Production Methods

hdpe sheet cost

The method used to produce HDPE sheets can influence their cost as well. Sheets manufactured through advanced processes, such as extrusion, might be priced differently compared to those made via traditional methods. The complexity of the production process, the machinery involved, and the level of automation can lead to variations in pricing due to differences in labor and operational costs.

Market Demand and Availability

Just like any other commodity, the cost of HDPE sheets can fluctuate based on market demand and availability. Economic factors, such as oil prices, can indirectly affect the pricing of HDPE products, as polyethylene is derived from petroleum. During periods of high demand for construction materials or when certain industries experience growth, prices may increase accordingly. Conversely, if supply exceeds demand, prices may stabilize or decrease.

Shipping and Delivery Costs

When calculating the overall cost of HDPE sheets, it’s essential to consider shipping and delivery charges. The weight and volume of the sheets can contribute significantly to transportation expenses, especially if sourcing from a distant supplier. Additionally, expedited shipping services or special handling requirements may further complicate the final price.

Summary

In summary, understanding the cost of HDPE sheets involves consideration of multiple factors—material quality, size, production methods, market dynamics, and shipping costs. By taking these elements into account, buyers can make more informed decisions, ensuring they obtain the best value for their investment. Whether you’re in need of HDPE sheets for industrial applications or creative projects, being aware of these contributing factors can help you budget effectively and choose wisely in your procurement process.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025