Nov . 16, 2024 17:31 Back to list

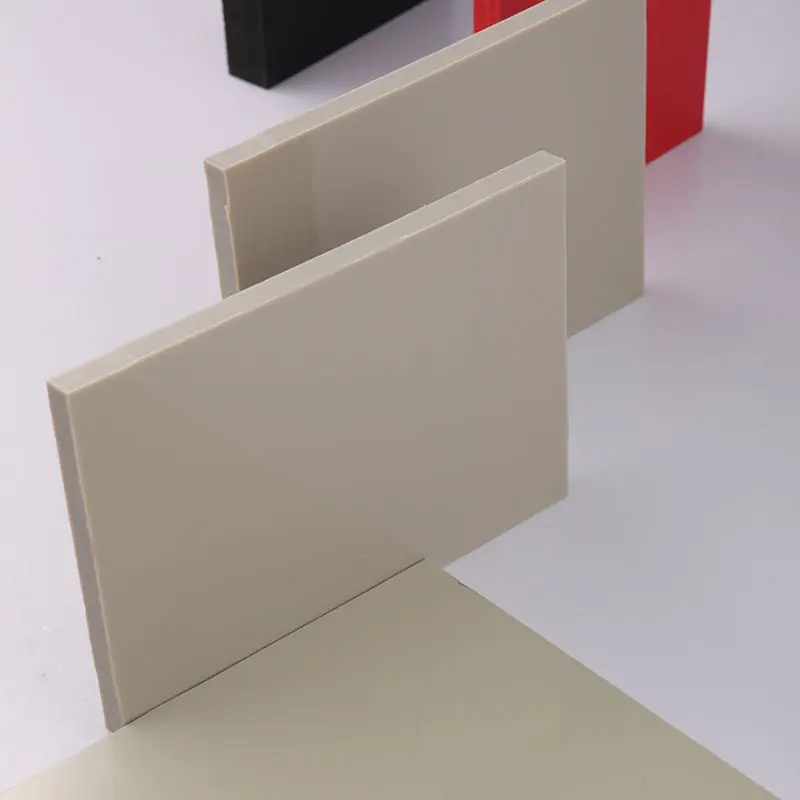

hdpe polythene sheet

Understanding HDPE Polythene Sheets Versatility and Applications

High-Density Polyethylene (HDPE) sheets are a popular material in various industries, known for their strength, durability, and versatility. Made from petrochemicals, HDPE is a type of thermoplastic that boasts a high strength-to-density ratio, making it an ideal choice for numerous applications, from construction to packaging.

One of the most significant advantages of HDPE sheets is their excellent resistance to impact, chemicals, and moisture. This makes them suitable for harsh environments where other materials might fail. The ability to withstand UV radiation also ensures that HDPE sheets retain their structural integrity when exposed to sunlight, a property that is highly beneficial in outdoor applications.

Understanding HDPE Polythene Sheets Versatility and Applications

Beyond construction, the packaging industry has significantly adopted HDPE due to its recyclable nature and the safety it offers. Many products, from bottles to containers, leverage HDPE’s food-safe properties, making them suitable for packaging food items. This contributes to not only ensuring the safety of consumables but also reducing plastic waste, as HDPE can be recycled multiple times without losing its integrity.

hdpe polythene sheet

Another key application of HDPE sheets is in the fabrication of custom parts and components. The ease of manufacturing and forming HDPE allows businesses to create tailored solutions for specific needs, including signs, displays, crates, and other specialty products. The durability of HDPE also results in a longer lifespan for these items, providing long-term value.

Moreover, HDPE sheets are increasingly finding their way into the agricultural sector. Farmers use these sheets for greenhouse construction, mulch film, and water management systems. The lightweight yet durable nature of HDPE ensures that it can withstand the rigors of outdoor use while providing farmers with essential tools for improving crop yields and sustainability.

Sustainability is a growing concern across industries, and HDPE sheets are contributing positively in this regard. Many manufacturers are now producing HDPE from recycled materials, thus reducing reliance on virgin plastics and lowering environmental impact. This circular approach to plastic use helps in addressing some of the pressing issues of plastic waste and promotes an eco-friendly approach to material sourcing and production.

In summary, HDPE polythene sheets exemplify a versatile material that plays a critical role across multiple sectors. Their unique combination of strength, resilience, and sustainability make them an essential choice for a wide range of applications. As industries continue to evolve and the demand for sustainable materials increases, HDPE sheets are likely to remain at the forefront, supporting innovation while addressing environmental concerns. By leveraging the benefits of HDPE, businesses and consumers can contribute to a more sustainable future, making informed choices that promote responsible consumption and production practices.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025