Nov . 04, 2024 20:22 Back to list

hdpe plastic welding rods

Understanding HDPE Plastic Welding Rods Applications and Benefits

High-Density Polyethylene (HDPE) is one of the most widely used plastics due to its durability, chemical resistance, and versatile properties. HDPE plastic welding rods are essential tools in various industries for joining HDPE materials through welding processes. In this article, we will explore the characteristics, applications, and advantages of HDPE plastic welding rods.

What Are HDPE Plastic Welding Rods?

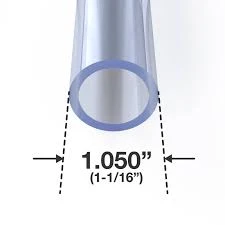

HDPE plastic welding rods are sticks or strips made from high-density polyethylene. These rods are specifically designed for welding applications and are compatible with HDPE materials. They come in various diameters and lengths, allowing for flexibility based on the specific welding requirements. Typically, these rods are manufactured from the same material as the workpieces, ensuring strong bonding and effective fusion during the welding process.

The Welding Process

The process of welding HDPE involves heating the rod and the base material to a point where they melt and fuse together. Typically, this involves using specialized equipment like hot air welders or extrusion welders. The welding rod is either fed into the welding point or held in place using a hot air tool, where the heated surfaces create a strong bond once they cool down. This method is highly effective for repairing, modifying, or creating new HDPE structures.

Applications of HDPE Plastic Welding Rods

HDPE plastic welding rods are used in various applications across different industries

. Some common uses include1. Aquaculture and Water Treatment HDPE is widely used in the construction of tanks, pipes, and other structures used in aquaculture and water treatment facilities. Welding rods help create strong, leak-proof joints that are essential for the integrity of these systems.

2. Construction and Civil Engineering In civil engineering, HDPE materials are used for drainage systems, liners for landfills, and road construction. Welding rods play a crucial role in ensuring these structures are waterproof and durable.

hdpe plastic welding rods

3. Manufacturing and Fabrication Many manufacturers use HDPE for creating products like containers, pallets, and crates. Welding rods allow for easy assembly and repair of these items, extending their lifespan and reducing waste.

4. Repair Work HDPE welding rods are also used for repairing broken or cracked HDPE items. Instead of discarding a damaged product, a welder can effectively repair it using these rods, making it both cost-effective and environmentally friendly.

Benefits of Using HDPE Plastic Welding Rods

The use of HDPE plastic welding rods comes with several significant benefits

1. Durability The welded joints created using HDPE rods are as strong, if not stronger, than the original material. This ensures long-lasting products that can withstand harsh environments.

2. Cost-Effectiveness By using welding rods for repairs and assembly, businesses can save on costs associated with replacing entire sections of material or entire products.

3. Ease of Use HDPE plastic welding rods are straightforward to work with and require minimal training. Even novice welders can achieve satisfactory results with the right equipment and technique.

4. Environmental Responsibility Utilizing welding rods to repair and maintain HDPE products reduces waste and promotes sustainability. Instead of discarding materials, businesses can extend the life of their products significantly.

Conclusion

In summary, HDPE plastic welding rods are invaluable tools in a variety of industries. Their ease of use, cost-effectiveness, and environmental benefits make them an excellent choice for anyone working with HDPE materials. Whether for construction, manufacturing, aquaculture, or repair, understanding the applications and advantages of HDPE welding rods can greatly enhance operational efficiency and sustainability. As industries continue to evolve, the significance of HDPE and its welding solutions will undoubtedly continue to grow.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025