Dec . 07, 2024 17:28 Back to list

hdpe cutting board sheets

Understanding HDPE Cutting Board Sheets Benefits, Uses, and Care

High-Density Polyethylene (HDPE) cutting board sheets have gained significant popularity in both commercial and residential kitchens due to their versatile applications, durability, and safety features. As a type of thermoplastic made from petroleum, HDPE is renowned for its strength, lightweight nature, and resistance to impact and moisture. This article delves into the benefits, uses, and maintenance of HDPE cutting board sheets, illustrating why they have become a staple in culinary environments.

Benefits of HDPE Cutting Board Sheets

1. Durability and Longevity One of the standout features of HDPE cutting board sheets is their durability. These boards can withstand heavy use without warping, cracking, or taking on odors. Unlike wooden or bamboo cutting boards, HDPE boards are less susceptible to knife marks, making them a preferred choice for professional chefs who require reliable equipment.

2. Hygienic Properties HDPE is a non-porous material that doesn’t harbor bacteria or moisture, making it an excellent choice for food preparation. The seamless surface of HDPE makes it easy to clean and sanitize, reducing the risk of cross-contamination between different food items. Additionally, they can safely be washed in a dishwasher, saving valuable time in busy kitchens.

3. Food Safety Many HDPE cutting boards are manufactured to meet regulatory standards for food safety. They are made without harmful chemicals and are often FDA-approved, ensuring that no substances leach into food during preparation. This aspect is crucial, especially in professional settings where food safety is of utmost importance.

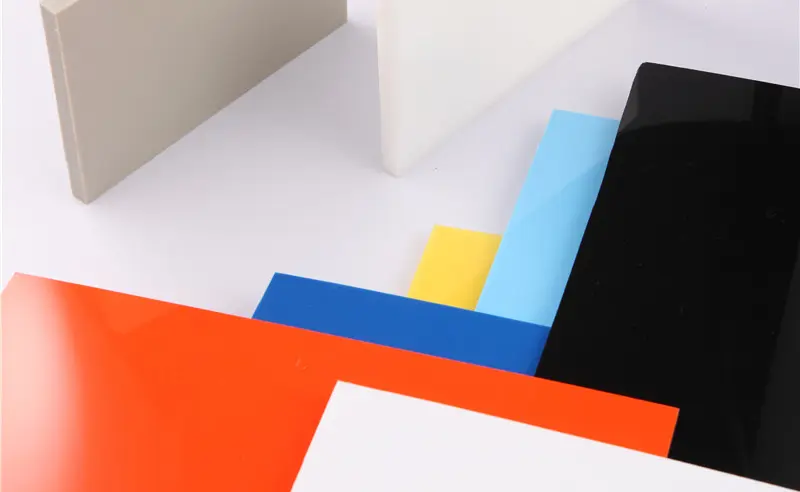

4. Color-Coded Options HDPE cutting board sheets are available in a variety of colors, which allows for a color-coded system in food preparation. By using different colored boards for different food groups (like raw meat, fruits, and vegetables), chefs can significantly reduce the risk of cross-contamination and streamline their food prep processes.

5. Economic Value While initial costs may vary, the long lifespan of HDPE cutting boards means they offer great value over time. Their resilience against wear and tear means they do not need to be replaced as frequently as other materials might.

hdpe cutting board sheets

Uses of HDPE Cutting Board Sheets

HDPE cutting board sheets serve a wide array of purposes beyond just slicing fruits and vegetables. They are ideal for

- Meat Processing Due to their safety features and ease of cleaning, HDPE boards are often used in the butchering industry. - Deli Slicing The smooth, sturdy surface allows for precise cuts and is easy to maintain in delis and sandwich shops. - Roll-out Surfaces Their sturdy, flat surfaces are perfect for rolling out dough or preparing meals without worry. - Crafting and DIY Projects Beyond the kitchen, HDPE sheets are also popular in crafting due to their durability and flexibility.

Care and Maintenance

Caring for HDPE cutting board sheets is straightforward, which further enhances their appeal. Here are some simple tips to keep them in great condition

- Cleaning After use, rinse with hot water and soap. For deeper cleaning, they can be scrubbed with a brush and surface cleaner or run through a dishwasher. - Avoiding Damage While HDPE is tough, avoiding exposure to extreme heat or flame is advisable, as this can warp the material. - Storage Store the boards flat to prevent warping and maintain their shape.

In conclusion, HDPE cutting board sheets are a practical and reliable choice for chefs and home cooks alike. Their durability, hygiene, and versatility make them an essential tool in any kitchen. Whether you're slicing vegetables or preparing meats, investing in quality HDPE cutting boards can significantly enhance your food preparation experience.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025