Jun . 20, 2024 02:05 Back to list

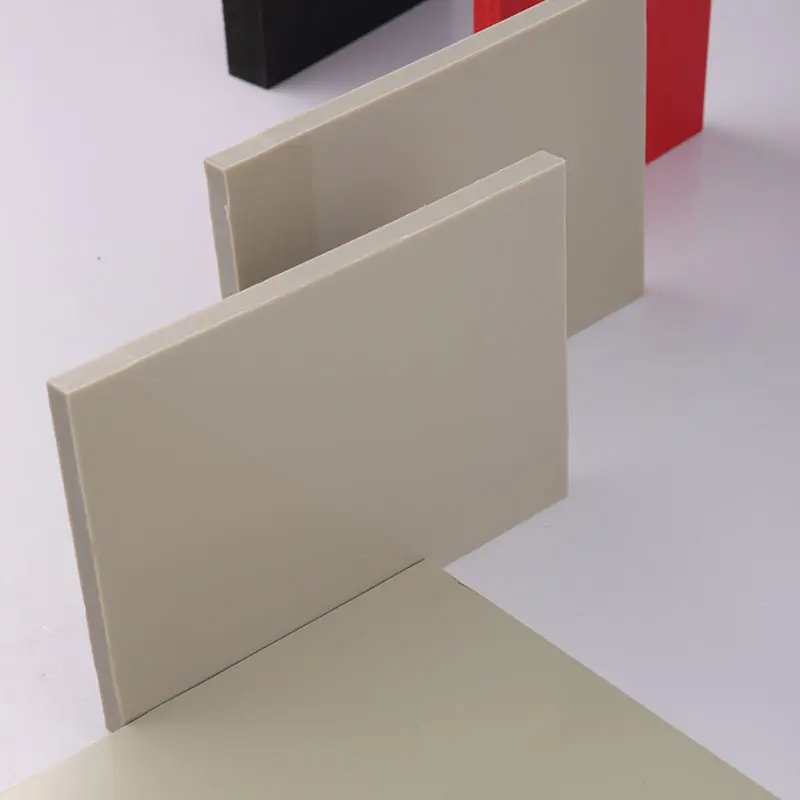

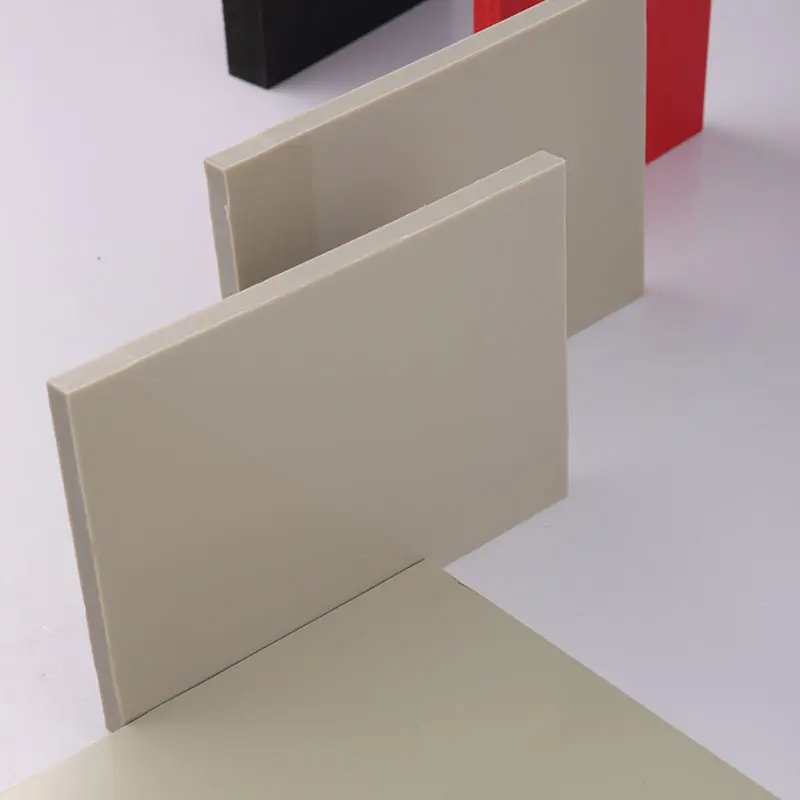

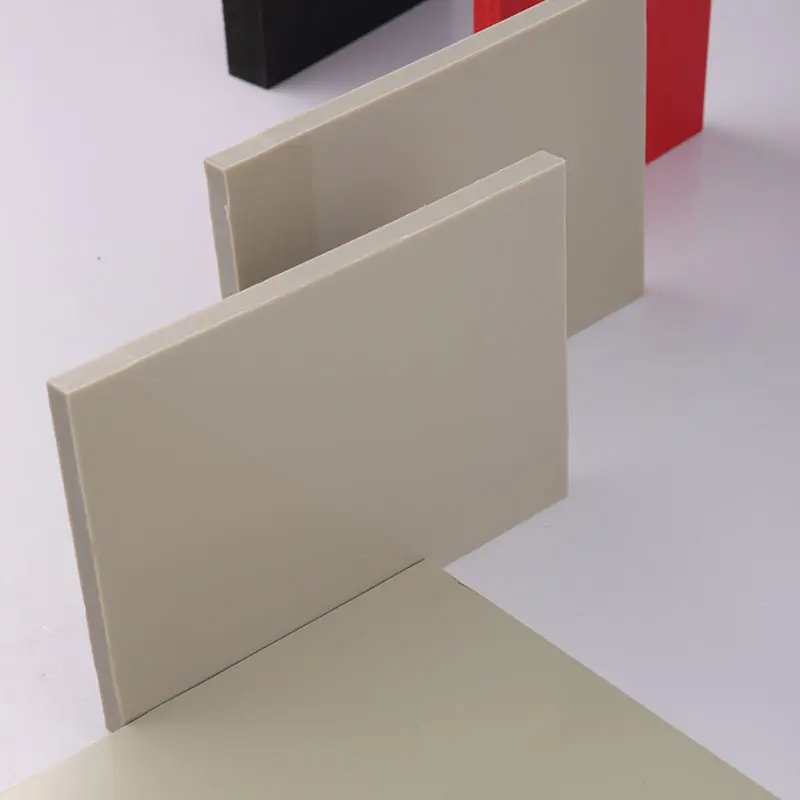

HDPE sheet's depth measurement

Understanding HDPE Sheets A Focus on Thickness Variations

High-Density Polyethylene (HDPE) sheets have emerged as a versatile and robust material in various industries due to their exceptional durability, chemical resistance, and impact strength. A key aspect that influences the performance and application of these sheets is their thickness. This article delves into the significance of HDPE sheet thickness and its implications on the material's usability.

HDPE sheets come in a broad range of thicknesses, typically varying from 1mm to over 50mm. The thickness of an HDPE sheet directly impacts its mechanical properties, such as tensile strength, flexural modulus, and impact resistance. Thicker sheets, for instance, are more suitable for applications requiring higher load-bearing capacity or impact resistance, such as industrial flooring, chemical storage tanks, and construction projects.

In contrast, thinner HDPE sheets, like those in the 1mm to 3mm range, find their niche in packaging, food industry, and manufacturing of small parts due to their ease of processing and lower weight. They offer excellent barrier properties against moisture and chemicals, making them ideal for storage solutions.

The choice of HDPE sheet thickness also plays a crucial role in determining the sheet's thermal stability and electrical insulation properties. Thicker sheets generally have better heat resistance, while thinner sheets provide superior electrical insulation due to their smaller cross-sectional area Thicker sheets generally have better heat resistance, while thinner sheets provide superior electrical insulation due to their smaller cross-sectional area Thicker sheets generally have better heat resistance, while thinner sheets provide superior electrical insulation due to their smaller cross-sectional area Thicker sheets generally have better heat resistance, while thinner sheets provide superior electrical insulation due to their smaller cross-sectional area

Thicker sheets generally have better heat resistance, while thinner sheets provide superior electrical insulation due to their smaller cross-sectional area Thicker sheets generally have better heat resistance, while thinner sheets provide superior electrical insulation due to their smaller cross-sectional area hdpe sheet thickness.

Moreover, the thickness of HDPE sheets affects their fabrication and installation processes. Thicker sheets often require specialized cutting and welding techniques, whereas thinner sheets can be easily cut with common tools. It is worth noting that thicker sheets may also need additional support during installation to prevent deformation under load.

When selecting the appropriate HDPE sheet thickness, it is essential to consider factors such as the intended application, environmental conditions, expected loads, and the required lifespan of the product. Consulting with manufacturers or experts can ensure the best-suited thickness is chosen, striking a balance between functionality, cost-effectiveness, and longevity.

In conclusion, the thickness of HDPE sheets is not just a physical characteristic but a critical determinant of their performance and suitability in different applications. It is a parameter that should be carefully evaluated to maximize the benefits offered by this resilient polymer. Whether you need a thick HDPE sheet for heavy-duty applications or a thin one for precision manufacturing, understanding the implications of thickness will undoubtedly lead to a more informed decision-making process.

hdpe sheet thickness.

Moreover, the thickness of HDPE sheets affects their fabrication and installation processes. Thicker sheets often require specialized cutting and welding techniques, whereas thinner sheets can be easily cut with common tools. It is worth noting that thicker sheets may also need additional support during installation to prevent deformation under load.

When selecting the appropriate HDPE sheet thickness, it is essential to consider factors such as the intended application, environmental conditions, expected loads, and the required lifespan of the product. Consulting with manufacturers or experts can ensure the best-suited thickness is chosen, striking a balance between functionality, cost-effectiveness, and longevity.

In conclusion, the thickness of HDPE sheets is not just a physical characteristic but a critical determinant of their performance and suitability in different applications. It is a parameter that should be carefully evaluated to maximize the benefits offered by this resilient polymer. Whether you need a thick HDPE sheet for heavy-duty applications or a thin one for precision manufacturing, understanding the implications of thickness will undoubtedly lead to a more informed decision-making process.

Thicker sheets generally have better heat resistance, while thinner sheets provide superior electrical insulation due to their smaller cross-sectional area Thicker sheets generally have better heat resistance, while thinner sheets provide superior electrical insulation due to their smaller cross-sectional area

Thicker sheets generally have better heat resistance, while thinner sheets provide superior electrical insulation due to their smaller cross-sectional area Thicker sheets generally have better heat resistance, while thinner sheets provide superior electrical insulation due to their smaller cross-sectional area hdpe sheet thickness.

Moreover, the thickness of HDPE sheets affects their fabrication and installation processes. Thicker sheets often require specialized cutting and welding techniques, whereas thinner sheets can be easily cut with common tools. It is worth noting that thicker sheets may also need additional support during installation to prevent deformation under load.

When selecting the appropriate HDPE sheet thickness, it is essential to consider factors such as the intended application, environmental conditions, expected loads, and the required lifespan of the product. Consulting with manufacturers or experts can ensure the best-suited thickness is chosen, striking a balance between functionality, cost-effectiveness, and longevity.

In conclusion, the thickness of HDPE sheets is not just a physical characteristic but a critical determinant of their performance and suitability in different applications. It is a parameter that should be carefully evaluated to maximize the benefits offered by this resilient polymer. Whether you need a thick HDPE sheet for heavy-duty applications or a thin one for precision manufacturing, understanding the implications of thickness will undoubtedly lead to a more informed decision-making process.

hdpe sheet thickness.

Moreover, the thickness of HDPE sheets affects their fabrication and installation processes. Thicker sheets often require specialized cutting and welding techniques, whereas thinner sheets can be easily cut with common tools. It is worth noting that thicker sheets may also need additional support during installation to prevent deformation under load.

When selecting the appropriate HDPE sheet thickness, it is essential to consider factors such as the intended application, environmental conditions, expected loads, and the required lifespan of the product. Consulting with manufacturers or experts can ensure the best-suited thickness is chosen, striking a balance between functionality, cost-effectiveness, and longevity.

In conclusion, the thickness of HDPE sheets is not just a physical characteristic but a critical determinant of their performance and suitability in different applications. It is a parameter that should be carefully evaluated to maximize the benefits offered by this resilient polymer. Whether you need a thick HDPE sheet for heavy-duty applications or a thin one for precision manufacturing, understanding the implications of thickness will undoubtedly lead to a more informed decision-making process. Share:

Latest news

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025