Oct . 07, 2025 11:20 Back to list

HDPE Natural Sheet: Food-Grade, Machinable, Cut to Size?

Field Notes from the Floor: HDPE Natural Sheet in Real-World Production

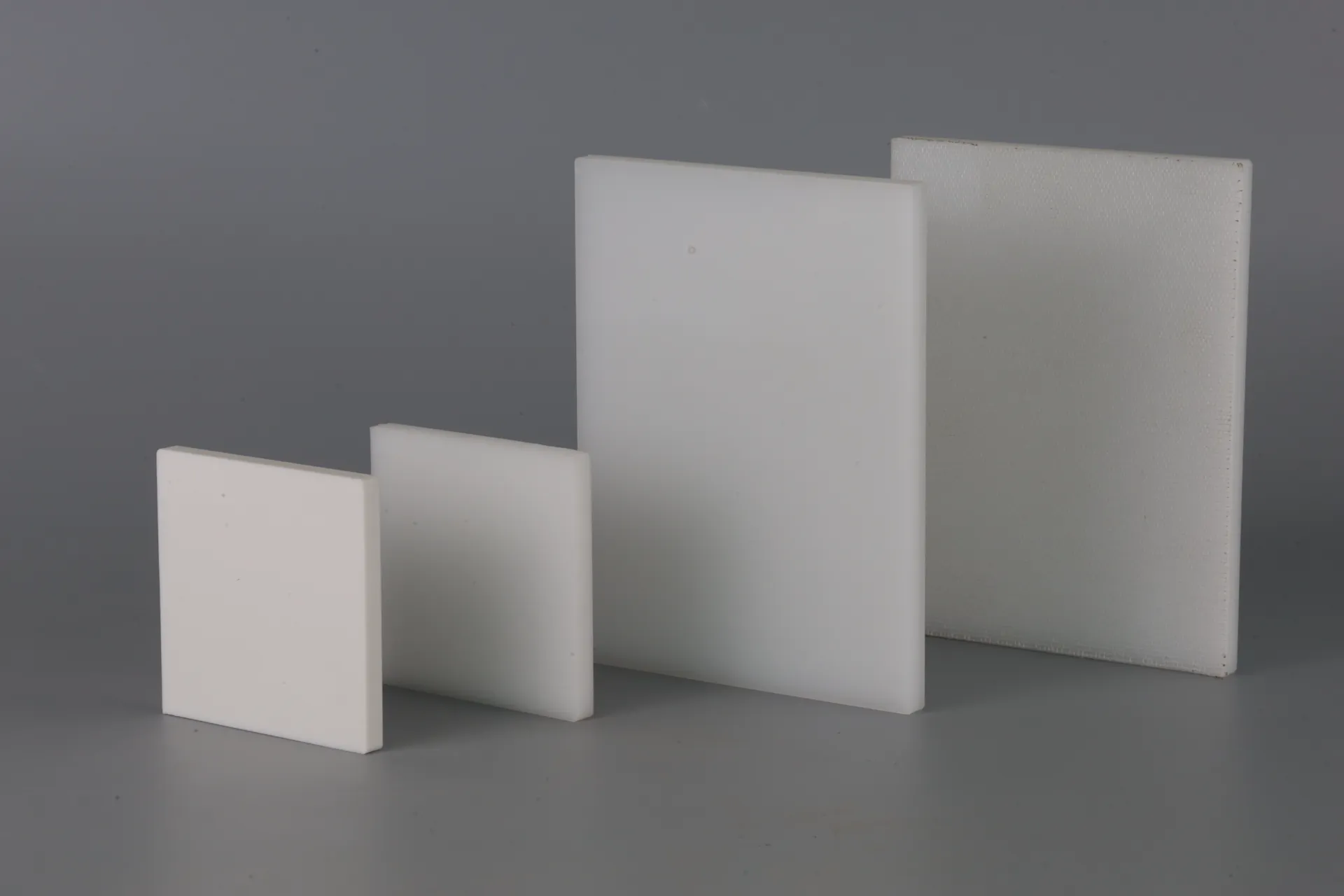

If you walk through any modern fab shop or food plant, you’ll see it everywhere—sliding quietly under conveyors, lining bins, taking abuse on cutting tables. I’m talking about HDPE Natural Sheet. It’s the unglamorous workhorse that, frankly, saves maintenance teams a lot of headaches. This season, I toured suppliers in Hebei and coastal factories, and one theme kept coming up: buyers want traceable resin, consistent flatness, and quick customization, without the “specialty plastic” price tag.

Why the industry is leaning harder into HDPE Natural Sheet

Three big trends: food-contact compliance, chemical resistance for water treatment retrofits, and machinable parts for quick-turn maintenance. To be honest, the price/performance ratio is the hook. Users tell me the material “just runs”—less stick-slip, fewer stress cracks, and easy cleaning. Surprisingly, even small OEMs are now asking for mill certs and lot traceability.

Key Specs (typical, real-world use may vary)

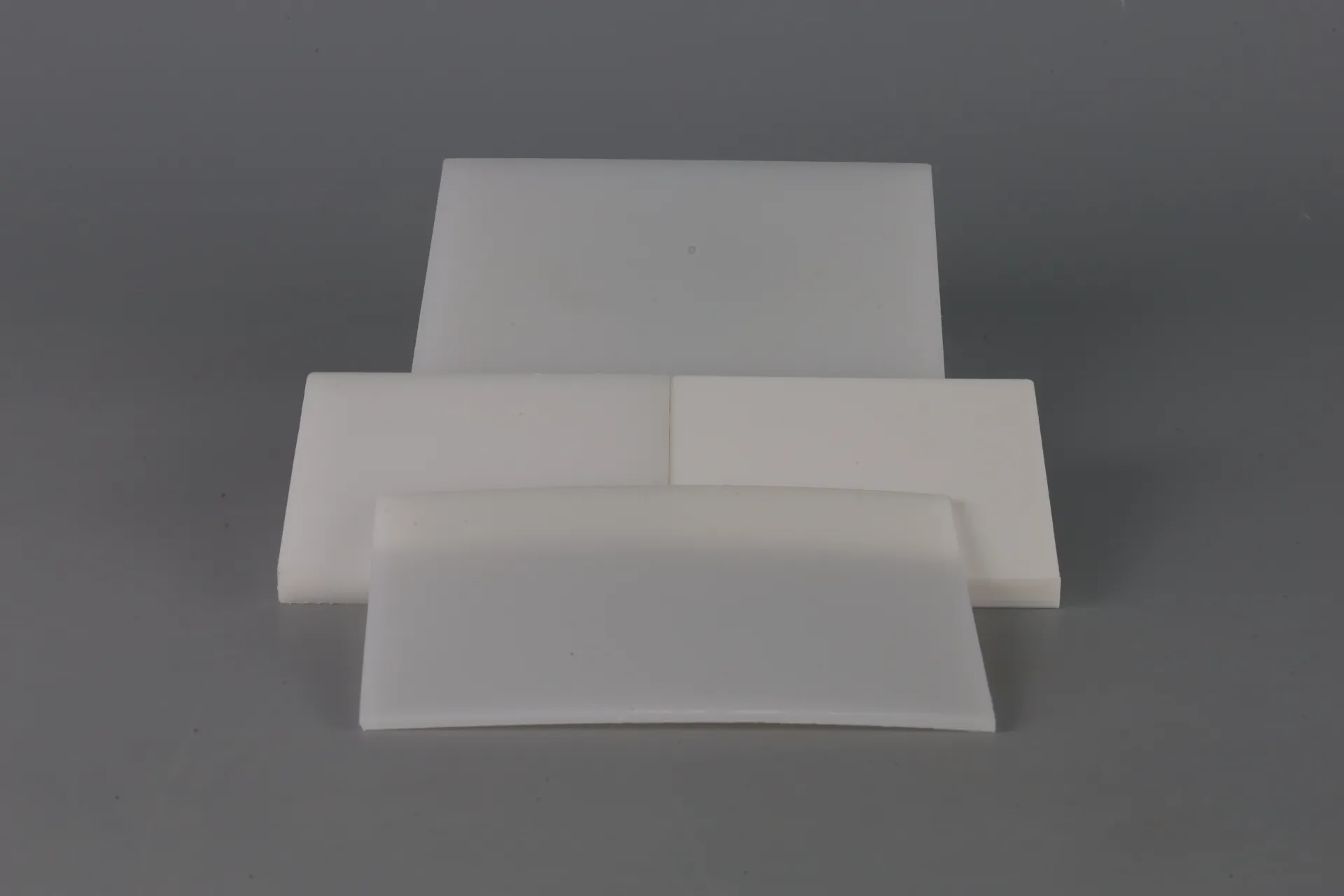

| Thickness | 3–20 mm (≈0.12–0.79 in) |

| Width | 1000–1600 mm |

| Length | Any length (cut-to-size available) |

| Surface / Color | Glossy; Natural, Black, or custom colors |

| Density (ISO 1183) | ≈0.95 g/cm³ |

| Tensile Strength (ASTM D638) | ≈20–31 MPa |

| Water Absorption (ISO 62) | ≤0.01%/24h |

From resin to sheet: how it’s made (short version)

Materials: prime HDPE resin (usually PE300/PE500 grades), UV stabilizer on request.

Methods: gravity-fed extrusion → calendaring/leveling → controlled cooling → trimming → aging/flatness conditioning.

Testing: melt flow (ISO 1133), thickness/flatness checks, tensile/elongation (ASTM D638), impact (ISO 179), and food-contact verification where required (FDA 21 CFR 177.1520).

Service life: around 5–15 years in general factory use; >10 years in indoor, non-UV environments. Outdoors with UV package, expect ≈5–8 years.

Where it’s used (and why it works)

- Food processing: cutting boards, side guides — low moisture uptake, easy sanitize.

- Water/wastewater: tank liners, baffles — chemical and corrosion resistance.

- Material handling: wear strips, chain guides — low friction, machinable.

- Marine/agriculture: dock fenders, chute liners — abrasion resistance.

- Packaging/OEM: shims, fixtures — stable, cost-effective.

Advantages users mention

- Consistent flatness on thicker gauges (less “potato chipping”).

- Good machinability with standard carbide tools; clean chips.

- Resists cracking under impact; doesn’t soak up water.

- Food-contact capable options; RoHS/REACH compliance on request.

Vendor snapshot and customization

| Vendor | Traceability | Flatness Control | Food-Contact Docs | Lead Time |

|---|---|---|---|---|

| Lida Plastic (Hebei) | Lot-based, COA available | Leveled + aging step | Yes (upon request) | ≈7–15 days |

| Market Average | Partial | Standard | Sometimes | ≈10–20 days |

| Low-Cost Import | Unknown | Variable | Rare | Uncertain |

Customization: cut-to-size, CNC machining, edge beveling, color matching, UV-stable or antistatic packages. Origin: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250.

Quick case study

A mid-sized poultry plant swapped wood-fiber boards for HDPE Natural Sheet (12 mm, natural, food-grade). Post-install checks: surface roughness stayed under 1.6 μm after 6 months, no measurable swelling (ISO 62 water soak), and blade wear decreased ≈12% per maintenance logs. Operators simply said, “It cleans faster.” Not scientific, but it tracks with our lab numbers.

Certifications and standards to ask for

- Material compliance: FDA 21 CFR 177.1520 (food contact), EU 10/2011 (if needed).

- RoHS/REACH declarations.

- Test reports: ASTM D638 (tensile), ISO 179 (impact), ISO 1133 (MFI), ISO 62 (water absorption).

Many customers say the real win is predictability. I guess that’s the most underrated feature of HDPE Natural Sheet: it behaves.

References

- ASTM D638 – Standard Test Method for Tensile Properties of Plastics.

- ISO 62 – Plastics — Determination of water absorption.

- ISO 1133 – Plastics — Determination of the melt mass-flow rate (MFR).

- FDA 21 CFR 177.1520 – Olefin polymers for food contact.

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025