Aug . 30, 2024 12:15 Back to list

High-Quality Gas Pipe Fittings for Secure Connections

Understanding Gas Pipe Fittings A Comprehensive Overview

When it comes to gas installations, safety, efficiency, and reliability are paramount. One key component in ensuring these qualities is the proper use of gas pipe fittings. These fittings are essential for connecting various pipes, allowing the flow of gas to different appliances and fixtures. In this article, we will explore the types, functions, and importance of gas pipe fittings.

Gas pipe fittings come in various shapes and sizes, each designed to serve a specific purpose in a gas installation system. Common types of fittings include elbows, tees, couplings, and unions. Elbows are used to change the direction of the gas flow, typically by 90 or 45 degrees. Tees allow for the branching of the gas line into two directions, while couplings connect two straight pipe sections together. Unions are similar to couplings but are designed for easy disconnection, which is useful for maintenance and repairs.

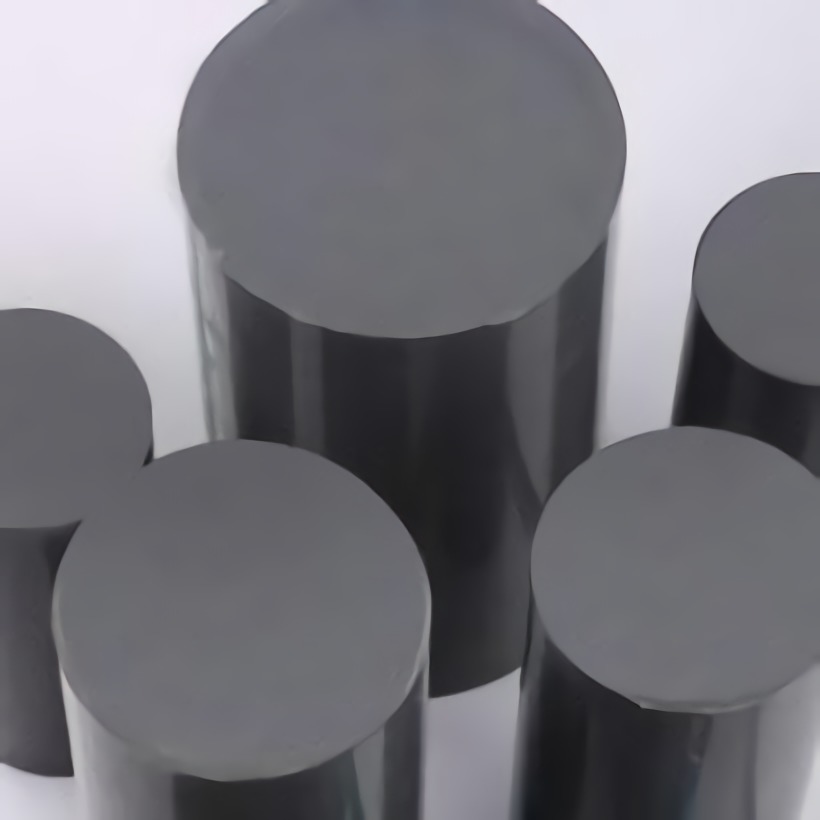

The materials used for gas pipe fittings are equally important. They are generally made from durable substances like steel, brass, or high-density polyethylene (HDPE). Steel fittings are favored for their strength and resistance to corrosion, making them suitable for high-pressure gas environments. Brass fittings, known for their malleability and resistance to rust, are often used in residential applications. HDPE is more common in underground installations due to its resistance to corrosion and lightweight nature.

gas pipe fittings

The proper installation of gas pipe fittings is crucial for preventing leaks and ensuring a safe gas supply. Each fitting must be installed according to manufacturer specifications and local building codes. This often involves using thread sealants or Teflon tape on threaded fittings, ensuring a tight seal to avoid gas leaks. Regular inspections are also essential to ensure that fittings remain secure and in good condition over time.

Safety regulations dictate that gas installations should only be conducted by certified professionals. This is to ensure compliance with safety standards and to minimize hazards associated with gas leaks or explosions. It is recommended for homeowners to perform regular maintenance checks and to be vigilant for any signs of gas leaks, such as a hissing sound or a rotten egg odor, which often indicates the presence of odorants added to natural gas for detection.

In conclusion, gas pipe fittings are a critical component in the design and functionality of gas systems. Understanding the different types of fittings and their applications is essential for anyone involved in gas installation and maintenance. Ensuring proper installation and regular inspections not only enhances the performance of gas systems but, more importantly, safeguards the well-being of individuals and property. Prioritizing safety and compliance with regulations should always be the top priority in any gas-related project.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025