Jul . 29, 2024 18:05 Back to list

Exploring the Versatility and Applications of PVC Boards in Modern Construction and Design

The Versatility of PVC Board A Comprehensive Overview

Polyvinyl chloride (PVC) boards have gained immense popularity in various industries due to their remarkable properties and versatility. With the increasing demand for innovative building materials, PVC boards have emerged as a preferred choice for many applications, ranging from construction to signage and furniture production. This article delves into the characteristics, advantages, and applications of PVC boards, shedding light on why they have become a staple in modern manufacturing and design.

Characteristics of PVC Boards

PVC boards are made from polyvinyl chloride, a synthetic plastic polymer known for its durability and resilience. One of the primary characteristics of PVC boards is their lightweight nature, which makes them easy to handle and transport. Despite being light, they possess high strength and longevity, ensuring they can withstand various environmental conditions. Additionally, PVC boards are resistant to moisture, chemicals, and decay, making them suitable for both indoor and outdoor use.

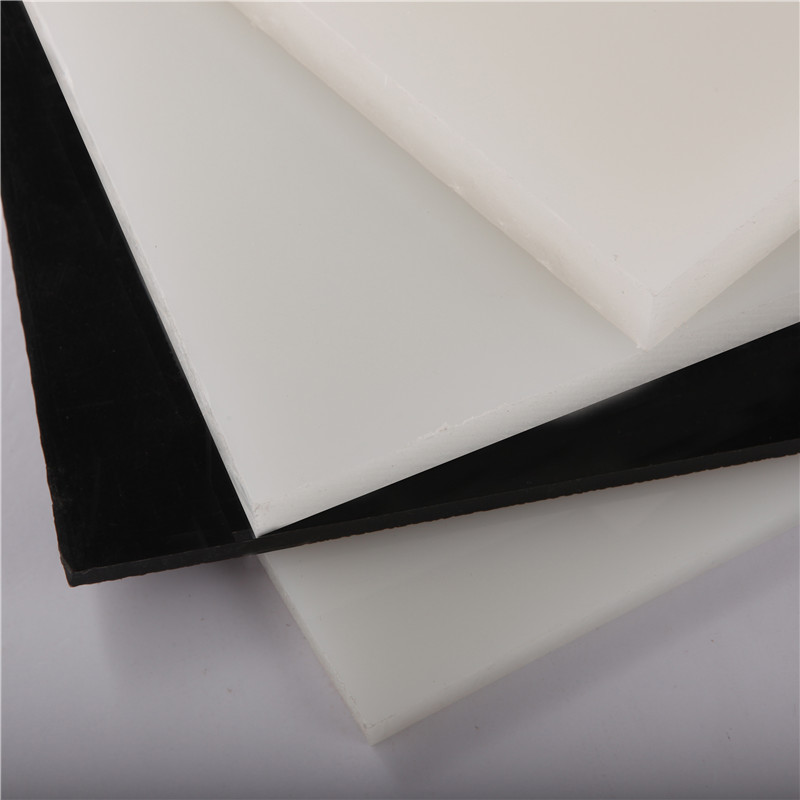

Furthermore, PVC boards are available in a variety of sizes, colors, and finishes. This flexibility allows designers and builders to customize their projects according to aesthetic and functional requirements. The surface of PVC boards can also be painted or laminated, enabling creative applications across different industries.

Advantages of Using PVC Boards

The benefits of using PVC boards are manifold. Firstly, their waterproof nature means they do not absorb moisture, reducing the risk of mold and mildew that often plagues traditional wooden materials. This characteristic alone makes PVC boards ideal for bathroom renovations, kitchens, and areas exposed to high humidity.

Another significant advantage is their low maintenance requirements. PVC boards do not require painting or sealing, saving both time and costs over the lifespan of the product. A simple wipe-down with soap and water is enough to keep them looking fresh and new.

The fire-retardant properties of PVC boards also add to their appeal, especially in applications where safety is a concern. Many PVC boards are manufactured to meet specific fire safety standards, making them suitable for use in commercial buildings and public spaces.

pvc board

Sustainability is becoming an increasingly important factor in material selection. PVC boards can be recycled, which alleviates some concerns regarding plastic waste. Many manufacturers are now adopting environmentally friendly practices, further enhancing the green credentials of PVC products.

Applications of PVC Boards

The applications of PVC boards are vast and varied. In construction, they are commonly used for wall cladding, ceiling tiles, and flooring due to their durability and aesthetic appeal. PVC boards can be easily cut and shaped, making them suitable for a wide range of structural elements.

In the signage industry, their weather-resistant properties make PVC boards ideal for outdoor signs, billboards, and displays. Additionally, their print-friendly surfaces allow for high-quality graphics, making them popular for promotional materials.

Furniture production has also adopted PVC boards for creating stylish and functional pieces. Tables, cabinets, and shelves made from PVC offer a modern aesthetic while being functional and durable.

In the realm of DIY projects, the versatility of PVC boards allows hobbyists and artisans to create unique home decor items, pet products, and more, further demonstrating their wide-ranging appeal.

Conclusion

In conclusion, PVC boards have established themselves as a crucial material in modern manufacturing and design due to their durability, versatility, and aesthetic appeal. Their unique properties make them suitable for an array of applications across various industries, from construction to furniture and signage. As sustainability becomes a focal point in material selection, the recyclable nature of PVC boards positions them as an environmentally conscious choice. With ongoing advancements in manufacturing technology, the future of PVC boards looks even brighter, promising innovative applications and solutions for years to come.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025