Aug . 06, 2024 05:56 Back to list

Exploring the Versatility and Applications of PVC Bars in Various Industries and Projects

The Versatile World of PVC Bars Applications and Advantages

Polyvinyl chloride, commonly known as PVC, is one of the most widely used synthetic plastic polymers in the world. Its robust and versatile nature has made it a preferred material in various industries. Among its many forms, PVC bars are particularly notable for their range of applications, superior properties, and cost-effectiveness. This article delves into the characteristics, uses, and benefits of PVC bars, shedding light on why they continue to gain popularity across different sectors.

What Are PVC Bars?

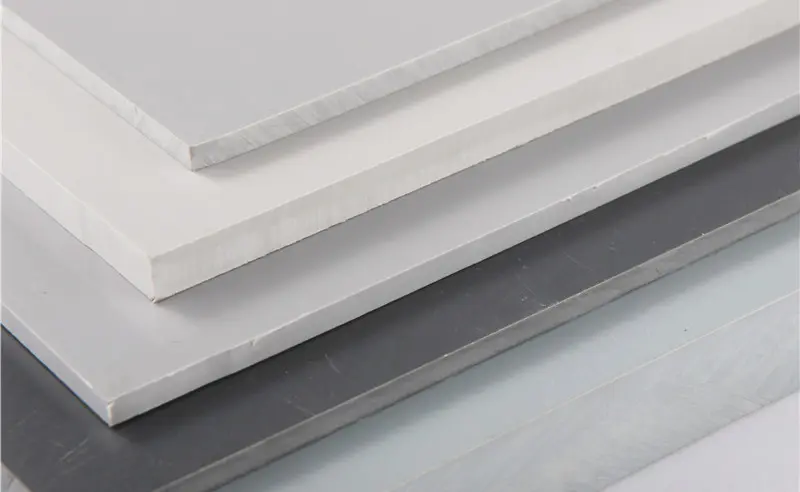

PVC bars are solid rectangular or cylindrical pieces made from polyvinyl chloride. They come in various sizes, colors, and thicknesses, making them suitable for specific requirements in diverse applications. Commonly used in manufacturing, construction, and crafting, these bars can be extruded, molded, or cast in a multitude of shapes to meet the needs of various projects.

Applications of PVC Bars

1. Construction and Building PVC bars are often used in building materials such as window frames, roofing sheets, and plumbing pipes. Their resistance to moisture and rot makes them ideal for outdoor applications, where exposure to weather conditions is inevitable.

2. Furniture Manufacturing Many modern furniture pieces incorporate PVC bars due to their lightweight yet strong nature. These bars are often used in the frames of chairs, tables, and other furniture items, providing durability without adding excessive weight.

3. Signage and Display The vibrant colors and ease of fabrication of PVC bars make them a preferred choice for signage and display fixtures. They can be easily cut, shaped, and printed upon, ensuring that businesses can create eye-catching signs that stand out.

4. Electrical Insulation With excellent electrical insulating properties, PVC bars are used extensively in the electrical industry for insulating components and ensuring safety in electrical installations.

pvc bar

5. Crafts and DIY Projects Hobbyists and artisans often utilize PVC bars for various crafts and DIY projects. Their versatility allows for intricate designs and sturdy structures, making them a favorite among crafters.

Advantages of PVC Bars

- Durability PVC bars are resistant to chemicals, moisture, and UV exposure, which contributes to their longevity. This durability ensures that products made from PVC require less frequent replacement, ultimately saving costs in the long run.

- Lightweight Compared to materials such as wood or metal, PVC bars are notably lightweight, making them easier to transport and work with, particularly in construction and manufacturing applications.

- Cost-Effectiveness PVC is generally more affordable than many alternative materials. The low-cost nature of PVC bars makes them an attractive option for large-scale projects, where budget constraints are often a concern.

- Environmental Considerations While PVC production has faced scrutiny in terms of environmental impact, advancements in recycling technologies have made it possible to recycle PVC products. Many manufacturers now adopt sustainable practices to minimize waste and promote reuse.

- Ease of Maintenance PVC bars are easy to clean and maintain, providing convenience for both residential and industrial applications. Their non-porous surface resists staining and can be quickly wiped clean.

Conclusion

In conclusion, PVC bars represent a remarkable blend of durability, versatility, and cost-effectiveness, making them invaluable across numerous industries. Their range of applications, from construction to crafting, illustrates how this material can meet diverse needs while providing significant advantages. As technology advances and environmental considerations become more prominent, the future of PVC bars seems promising, continuing to serve as a reliable solution for various projects. Whether you are in construction, manufacturing, or simply indulging in a DIY project, PVC bars are a resource worth considering for your next endeavor.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025