Aug . 14, 2024 19:58 Back to list

Exploring the Properties and Applications of CPVC Sheets for Industrial Uses and Projects

Understanding CPVC Sheets Properties, Applications, and Advantages

Chlorinated Polyvinyl Chloride, commonly known as CPVC, is a thermoplastic material that has gained popularity in various industries due to its unique properties and versatility. CPVC sheets are integral components in numerous applications, ranging from construction to manufacturing. This article delves into the characteristics, benefits, and common uses of CPVC sheets.

Properties of CPVC Sheets

One of the standout features of CPVC sheets is their remarkable resistance to temperature and chemicals. CPVC can withstand high temperatures, making it suitable for applications involving hot water and aggressive chemicals. Unlike standard PVC, CPVC is chlorinated, which enhances its thermal and chemical resistance. This property makes CPVC sheets highly effective in environments where exposure to harsh chemicals is commonplace, such as in chemical processing and wastewater management.

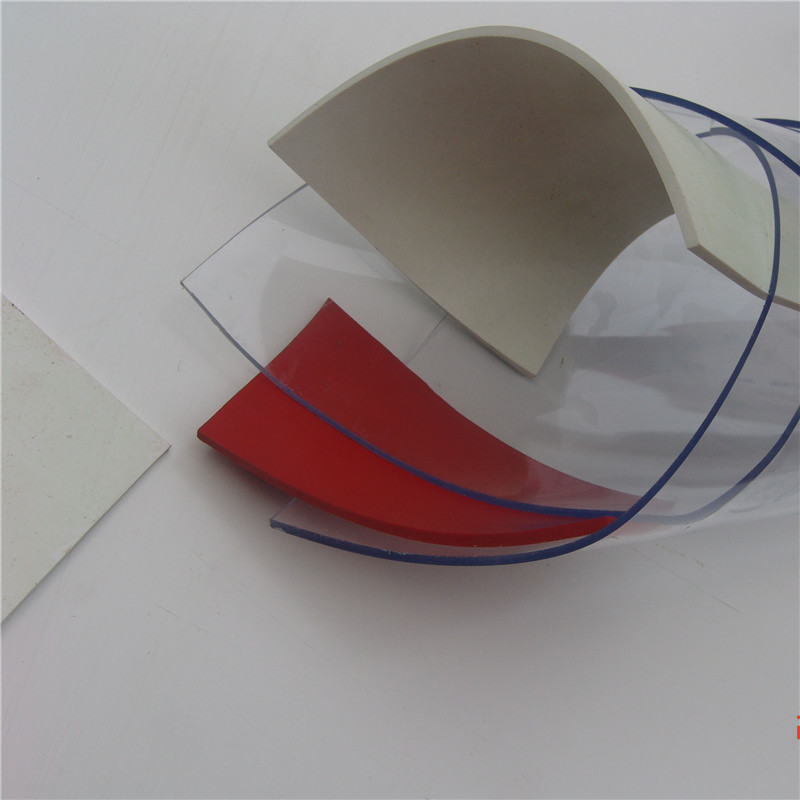

Moreover, CPVC sheets offer excellent mechanical strength, durability, and flexibility, which further broadens their range of applications. The sheets are available in various thicknesses and sizes, making them adaptable to specific design requirements. Additionally, CPVC is a lightweight material, which simplifies handling and installation processes.

Advantages of CPVC Sheets

One of the most significant advantages of CPVC sheets is their ability to resist corrosion. In industries where metal products often succumb to rust and degradation, CPVC serves as a reliable alternative. This quality not only extends the lifespan of the components but also reduces maintenance costs over time.

Another benefit is the ease of fabrication. CPVC sheets can be easily cut, shaped, and welded, allowing for customization to fit specific project needs. The ease of installation is further enhanced by the compatibility of CPVC with solvent cement, which simplifies joining and assembly processes.

cpvc sheet

Additionally, CPVC sheets boast a high level of fire resistance compared to many traditional plastic materials. Although they can melt when exposed to high temperatures, they tend to self-extinguish when the heat source is removed, providing an added layer of safety in building materials.

Applications of CPVC Sheets

CPVC sheets are widely used in various sectors due to their versatile properties. In the construction industry, they are often employed in roofing, siding, and wall cladding, providing effective insulation and durability. Their resistance to environmental factors like moisture and UV light makes them ideal for outdoor applications.

In the chemical industry, CPVC sheets are utilized for lining tanks, pipes, and ducts, ensuring that they can withstand corrosive substances without degrading. They are also prominent in the production of valves, fittings, and other plumbing components, especially in hot water systems.

Moreover, CPVC sheets find use in the manufacturing of electronic enclosures and automotive parts, where their lightweight and durable nature translates into improved performance.

Conclusion

In summary, CPVC sheets play a pivotal role in a variety of applications, thanks to their exceptional thermal, chemical, and mechanical properties. Their lightweight, corrosion-resistant nature, along with ease of installation, positions them as a preferred choice in many industries. As technology advances and the demand for durable materials continues to rise, the role of CPVC sheets is likely to expand even further, reinforcing their status as a vital component in modern construction and manufacturing. Whether in residential buildings or industrial facilities, CPVC sheets are proving to be an invaluable resource that meets the demands of contemporary society.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025