Aug . 17, 2024 08:56 Back to list

Exploring the Benefits and Applications of HDPE Panels in Various Industries

Understanding HDPE Panels Versatile Solutions for Modern Applications

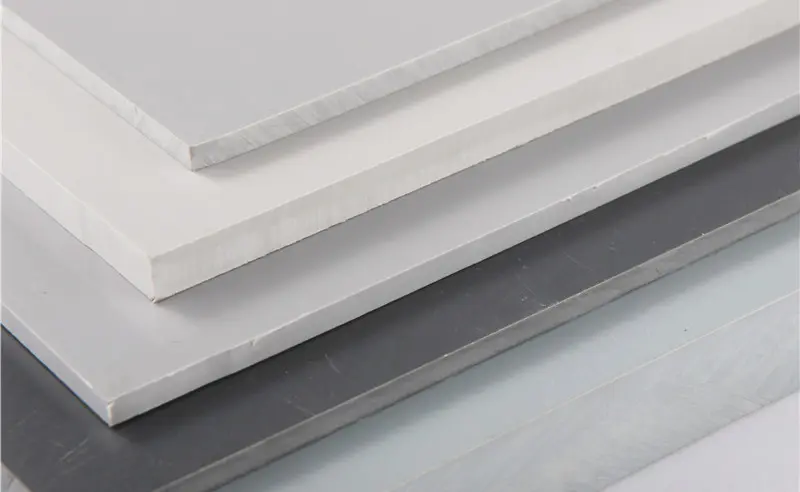

High-Density Polyethylene (HDPE) panels have gained considerable attention in recent years due to their remarkable versatility and durability. As a form of plastic, HDPE is known for its high strength-to-density ratio, making it an excellent choice for various applications ranging from construction to packaging. This article delves into the features, benefits, and diverse uses of HDPE panels, highlighting why they are becoming a preferred material in many industries.

Characteristics of HDPE Panels

HDPE panels are manufactured from high-density polyethylene, a polymer that is both lightweight and robust. One of the most noteworthy characteristics of HDPE is its resistance to impact, weathering, and various chemicals. This durability makes HDPE panels suitable for outdoor applications where they are exposed to harsh environmental conditions. Furthermore, they are non-toxic and recyclable, contributing to sustainability efforts in reducing plastic waste.

These panels can be engineered in varying thicknesses and sizes, making them adaptable to specific requirements. They also exhibit excellent resistance to UV rays, which prevents fading and degradation over time, ensuring longevity in outdoor installations. The smooth surface of HDPE panels also makes them easy to clean, which is essential in maintaining hygiene in both industrial and residential applications.

Advantages of HDPE Panels

One of the primary advantages of HDPE panels is their versatility. They can be used in numerous sectors, including construction, agriculture, packaging, and even in the automotive industry. Here are some primary benefits of using HDPE panels

1. Durability As mentioned earlier, HDPE is resistant to impact, chemicals, and the elements, which translates to a long lifespan and less frequent need for replacement.

2. Lightweight Despite their strength, HDPE panels are lightweight, which simplifies transportation and installation, making them an economical choice for various projects.

3. Cost-Effectiveness While the initial cost might be slightly higher than some alternative materials, the longevity and low maintenance of HDPE panels often result in lower overall costs.

hdpe panel

4. Eco-Friendly Being recyclable, HDPE panels can contribute to sustainable practices by reducing waste and conserving resources.

5. Safety HDPE panels do not leach harmful chemicals, ensuring safety in applications such as food packaging or medical equipment.

Applications of HDPE Panels

The applications of HDPE panels are diverse, showcasing their adaptability across different industries

- Construction HDPE panels are widely used for temporary structures, permanent installations like partitions, and even for waterproofing membranes due to their moisture resistance.

- Agriculture They serve as effective liners for ponds, reservoirs, and landfills, preventing leaks and contamination. They are also used in greenhouse construction and as protective barriers for crops.

- Packaging The strength and impermeability of HDPE make it an ideal material for packaging goods, particularly in industries that require durability and chemical resistance.

- Marine Use HDPE panels are resistant to saltwater corrosion, making them ideal for applications in marine environments, such as docks and boat components.

Conclusion

In conclusion, HDPE panels represent a modern solution for a myriad of applications. Their durability, lightweight characteristics, eco-friendliness, and versatility make them an attractive choice for industries looking to innovate while maintaining environmental responsibility. As technology advances, we can expect further developments in HDPE formulation and processing, which will inevitably expand its applications and benefits, solidifying its role as a critical component in contemporary manufacturing and construction practices. Whether in your backyard or on a construction site, HDPE panels are undoubtedly a material to watch in the future.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025