Oct . 16, 2024 17:37 Back to list

Durable PVC Welding Rods for Strong and Efficient Plastic Welding Solutions

Understanding Double PVC Welding Rods Features, Applications, and Benefits

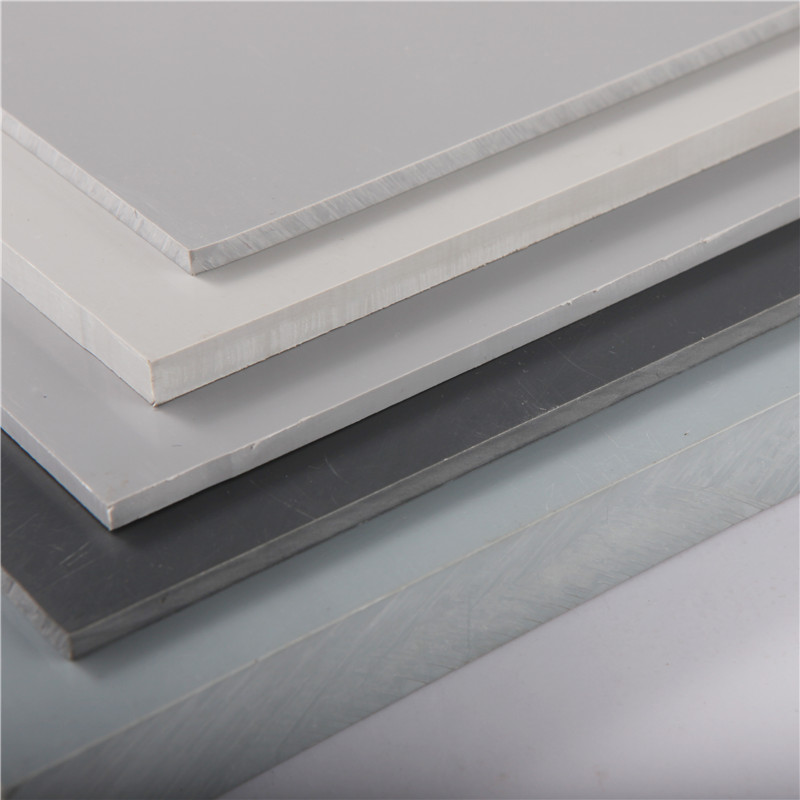

Double PVC welding rods are specialized materials used in the thermoplastic welding process, particularly in joining PVC (Polyvinyl Chloride) components. Given their unique properties and versatility, they have become increasingly popular in various industries, including construction, automotive, and manufacturing. This article aims to delve into the features, applications, and benefits of double PVC welding rods while highlighting their importance in modern industrial practices.

Features of Double PVC Welding Rods

Double PVC welding rods are crafted from high-quality PVC, ensuring excellent flexibility and durability. The term double refers to the rod's unique design, which often incorporates two distinct layers or a dual composition. This design enhances its performance during the welding process. Key features of double PVC welding rods include

1. Temperature Resistance These rods can withstand higher temperatures, making them ideal for applications that require heat application for joining materials.

2. Chemical Resistance PVC itself is resistant to many chemicals, and double PVC welding rods inherit this property, making them suitable for industrial environments where chemical exposure is a risk.

3. Improved Adhesion The dual composition typically enhances the adhesion properties, ensuring a more robust and durable weld.

4. Ease of Use Designed for ease of handling, these rods can be conveniently used with various welding equipment, making them a preferred choice for both professionals and DIY enthusiasts.

Applications of Double PVC Welding Rods

The versatility of double PVC welding rods extends to numerous applications across different sectors

. Some common uses include1. Construction In the construction industry, double PVC welding rods are used for joining piping systems, fabricating tanks, and constructing waterproof barriers. Their ability to form airtight seals makes them essential for plumbing and drainage systems.

double pvc welding rod

2. Automotive The automotive industry utilizes these rods for repairs and modifications of PVC components, including dashboards, trims, and even body parts. Their resilience and durability contribute to the longevity of the repairs.

3. Manufacturing Many manufacturers employ double PVC welding rods in producing various products, from furniture to signage. The rods facilitate efficient assembly processes and enhance the structural integrity of the final product.

4. Agriculture In agricultural settings, these rods are instrumental in creating durable and weather-resistant structures, such as greenhouses and storage tanks.

Benefits of Using Double PVC Welding Rods

The adoption of double PVC welding rods comes with several benefits that make them advantageous for both manufacturers and end-users

1. Cost-Effectiveness While the initial investment may be slightly higher than single-layer rods, the durability and extended life of the welds reduce the need for frequent repairs or replacements, resulting in long-term savings.

2. Enhanced Performance The superior adhesion and heat resistance ensure a quality weld, minimizing the risk of failures or leaks that could lead to costly downtimes.

3. Sustainability Many double PVC welding rods are manufactured with sustainability in mind, using recycled materials that contribute to reducing environmental impact.

4. Versatility Their adaptability across various industries means organizations can use the same type of welding rod for multiple applications, simplifying inventory management and training processes.

Conclusion

Double PVC welding rods have established themselves as vital components in the welding processes across numerous industries. Their unique features, diverse applications, and multitude of benefits make them an ideal choice for professionals seeking reliable and efficient welding solutions. As industries continue to evolve, the demand for such materials is likely to grow, making understanding their properties and uses essential for anyone involved in related fields.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025