Jul . 27, 2024 00:55 Back to list

Creating Engaging Content with PP Plate Techniques for Enhanced Audience Interaction and Response

Understanding PP Plates Applications, Benefits, and Future Prospects

Polypropylene (PP) plates, made from the thermoplastic polymer polypropylene, have gained significant attention across various industries. The versatility, durability, and cost-effectiveness of PP plates make them an excellent choice for diverse applications, from packaging to automotive components.

What are PP Plates?

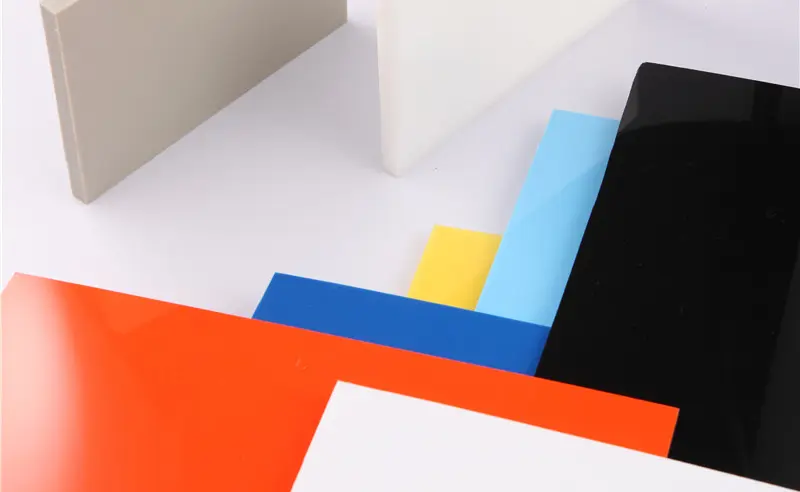

PP plates are flat sheets made from polypropylene resin, a type of plastic known for its excellent mechanical properties and chemical resistance. These plates can be produced in various thicknesses and colors, making them suitable for multiple uses. The lightweight nature of PP, combined with its rigidity and fatigue resistance, makes it a preferred material in many sectors.

Applications of PP Plates

1. Packaging Industry One of the most common uses of PP plates is in the packaging sector. Due to their high strength-to-weight ratio, these plates are ideal for producing containers, lids, and other packaging materials. Their resistance to moisture and chemicals ensures that products remain protected during transit.

2. Automotive Components In the automotive industry, PP plates are increasingly being utilized for manufacturing interior and exterior components. These plates contribute to reducing the overall weight of vehicles, enhancing fuel efficiency while maintaining structural integrity. Parts like dashboard components, battery trays, and bumpers often utilize PP plates.

3. Medical Applications The medical field also benefits from the properties of PP plates. They can be sterilized easily, making them suitable for use in laboratory equipment, medical trays, and other devices that require stringent hygiene standards. Their chemical resistance helps in preventing reactions with various substances used in medical settings.

pp plate

4. Construction and Furniture PP plates are employed in the construction industry for applications such as wall coverings, partitions, and false ceilings. Their durability and resistance to environmental conditions make them suitable for both indoor and outdoor use. In furniture design, PP plates are used to create sleek, modern pieces that are lightweight yet sturdy.

Benefits of PP Plates

The advantages of using PP plates are manifold

- Durability PP plates exhibit high impact resistance, making them long-lasting even in demanding environments. - Chemical Resistance They are impervious to many acids, bases, and solvents, which is crucial for both industrial and medical applications. - Cost-Effectiveness Compared to other materials, PP plates are relatively affordable, making them accessible for various industries. - Lightweight The low density of PP plates translates into reduced shipping costs and ease of handling during installation or assembly.

Sustainability and Future Prospects

As industries move towards more sustainable practices, the environmental impact of materials like PP plates is under scrutiny. While polypropylene is a synthetic polymer, advancements in recycling technologies are paving the way for more sustainable practices. Recycled PP can be reprocessed into new plates, reducing waste and the overall carbon footprint.

Looking ahead, the market for PP plates is expected to grow, driven by increasing demands from sectors like packaging and automotive. Innovations in material science may lead to the development of enhanced forms of PP plates, with improved properties and sustainability features.

In conclusion, PP plates represent a crucial material in modern industry, combining versatility with functionality. As businesses continue to seek efficient and sustainable solutions, the role of PP plates is likely to expand further, reinforcing their importance in the global marketplace. Whether in packaging, automotive, or medical applications, the future of PP plates looks promising.

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025

-

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025