Aug . 14, 2024 05:06 Back to list

Creating Engaging Activities for Team Collaboration in a Digital Workspace Environment

Understanding PP Board Versatility and Applications

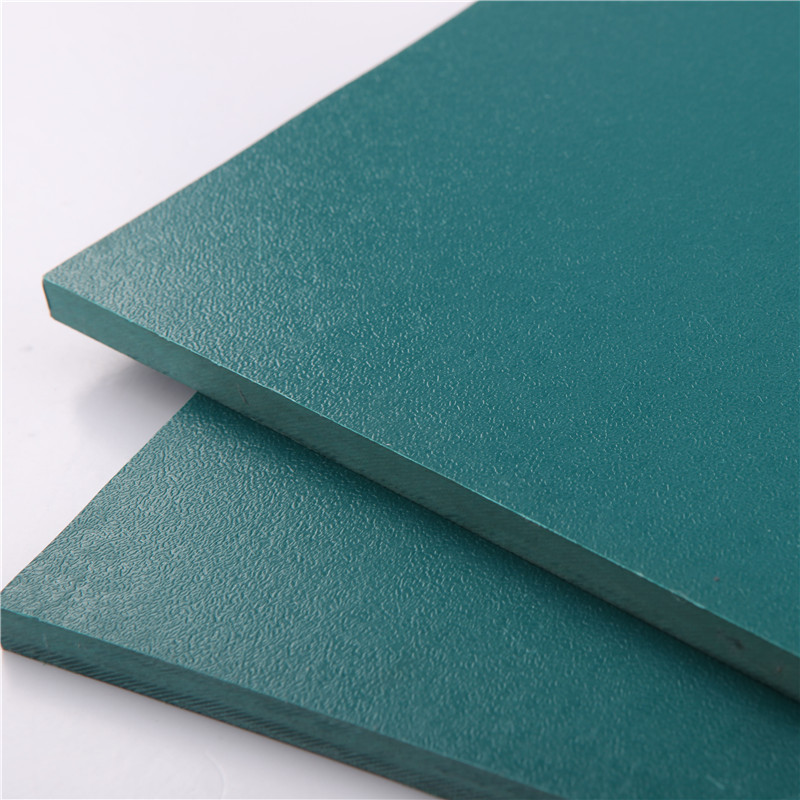

Polypropylene (PP) board, commonly referred to as PP sheet or PP plastic board, is a versatile thermoplastic material that has garnered popularity in various industries due to its unique properties and benefits. This material is made from polypropylene, a type of polymer that is lightweight, durable, and resistant to many chemicals, moisture, and impacts. In this article, we will explore the characteristics, applications, and advantages of PP board, highlighting why it is an excellent choice for numerous projects.

Characteristics of PP Board

One of the most notable features of PP board is its lightweight nature. Compared to other materials such as wood or metal, PP boards are significantly lighter, making them easier to handle and transport. Despite their lightness, they offer impressive strength and durability, capable of withstanding wear and tear from various external factors.

Additionally, PP boards are highly resistant to water and moisture. This makes them an ideal option for projects that may be exposed to damp conditions, such as in outdoor signage, packaging, or in environments like kitchens and laboratories. Furthermore, the chemical resistance of PP board allows it to be used in settings where it may come into contact with acids, bases, or solvents without degrading.

Another beneficial property is that PP sheets can be easily fabricated. They can be cut, drilled, and machined using standard tools, making them accessible for craftspeople and manufacturers alike. They can also be printed on, allowing for easy customization for branding and signage purposes.

Applications of PP Board

The versatility of PP board leads to a wide range of applications across various sectors. One common application is in packaging. Due to its lightweight and durable nature, PP board is often used for creating boxes, dividers, and packaging inserts that need to protect products during shipping and handling.

pp board

In the signage industry, PP boards are increasingly utilized for both indoor and outdoor signs. Their resistance to weathering ensures longevity, while the option for high-quality printing makes them ideal for conveying messages effectively. Whether it's promotional displays or permanent signage, PP boards provide aesthetic appeal without compromising resilience.

PP boards also find uses in construction and architecture. They can be employed as wall panels, partitions, or even as temporary structures for exhibitions and trade shows due to their structural integrity. Moreover, their ability to be fabricated into different shapes allows for innovative design solutions.

Another area of application is in the medical field, particularly in the production of trays and containers that are used for medical instruments and supplies. The material's non-toxic nature and chemical resistance make it safe for use in sterile environments.

Environmental Considerations

While PP board has many advantages, it is also worth noting the evolving emphasis on sustainability. Polypropylene is recyclable, and using recycled PP in manufacturing can help reduce waste. Therefore, choosing PP board can be part of a broader commitment to fostering sustainable practices in manufacturing and consumption.

Conclusion

In summary, PP board is a remarkable material that embodies versatility, durability, and ease of use, making it an excellent choice for a multitude of applications. From packaging and signage to construction and medical uses, its unique properties make it a preferred option in various industries. As technological advancements continue to improve the production processes and sustainability of PP materials, its role in future applications is likely to expand, reinforcing its position as a critical material in modern manufacturing and design. Understanding the benefits and applications of PP board can help businesses and consumers make informed decisions that harness its full potential.

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025