Nov . 26, 2024 23:42 Back to list

Understanding CPVC Welding Rods for Effective Pipe Joining Techniques

Understanding CPVC Welding Rods Features and Applications

Chlorinated Polyvinyl Chloride (CPVC) welding rods are specialized materials designed for joining CPVC pipes and fittings in various applications, particularly in plumbing and industrial systems. CPVC is a thermoplastic polymer known for its excellent chemical resistance, high-temperature tolerance, and durability, making it a popular choice in numerous fields. In this article, we will delve into the features, benefits, and applications of CPVC welding rods.

Features of CPVC Welding Rods

1. Chemical Resistance One of the standout features of CPVC welding rods is their impressive resistance to a wide range of chemicals, including acids, alkalis, and salts. This property makes CPVC the material of choice in chemical processing industries where safety and durability are paramount.

2. High-Temperature Tolerance CPVC can withstand higher temperatures compared to regular PVC. With a temperature rating of up to 200°F (93°C), it performs exceptionally well in hot water applications, making it ideal for plumbing and heating systems.

3. Easy to Use The welding process for CPVC rods involves the application of heat to fuse the materials together. This process is relatively straightforward and can be performed with common welding equipment, making it accessible for both professionals and DIY enthusiasts.

4. Durability and Longevity CPVC welding rods create strong joints that contribute to the longevity of the systems where they are used. They are resistant to corrosion and degradation, ensuring that installations remain effective for many years without needing frequent repairs or replacements.

5. Versatility These rods can be used in a variety of applications, including residential and commercial plumbing, industrial piping systems, and even fire sprinkler systems. Their versatility allows for a range of configurations and installations.

Benefits of Using CPVC Welding Rods

- Cost-Effective CPVC systems tend to require less maintenance over time due to their durability. This can lead to significant savings in both repairs and operational costs, making them a cost-effective choice for various applications.

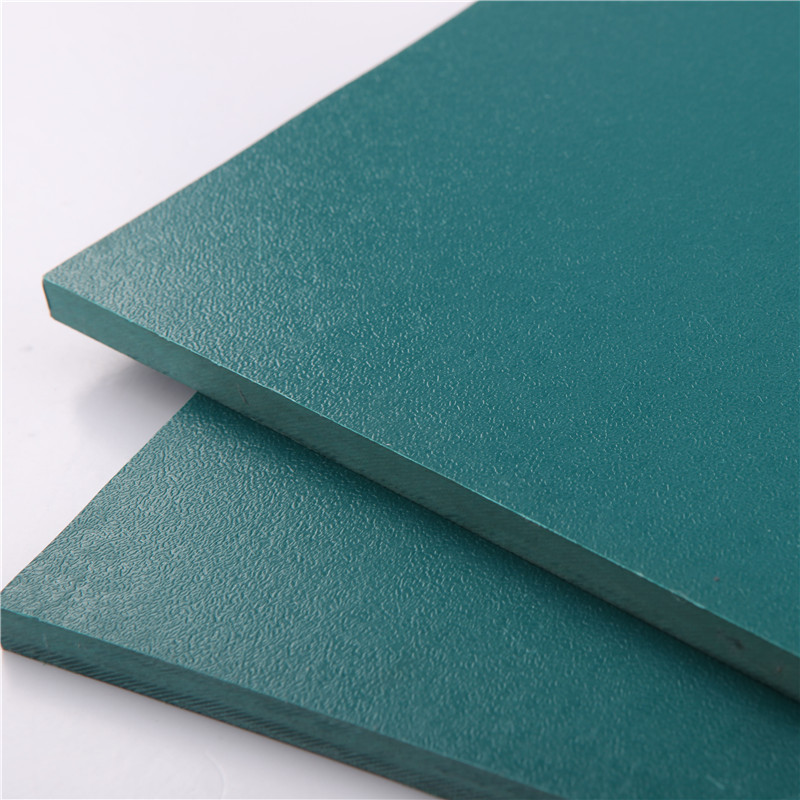

cpvc welding rod

- Environmentally Friendly CPVC is a recyclable material, which reduces the environmental impact of installations. Additionally, the long lifespan of CPVC systems means less waste is generated from replacements and repairs.

- Improved Safety With robust chemical resistance and the ability to handle high temperatures, CPVC systems minimize the risk of leaks and failures, ensuring safer operations in both commercial and residential settings.

- Ease of Installation The lightweight nature of CPVC makes it easier to transport and install. This can lead to reduced labor costs and faster project completion times.

Applications of CPVC Welding Rods

CPVC welding rods are used in various applications across different industries, including

- Plumbing CPVC is widely used in residential and commercial plumbing systems for hot and cold water distribution.

- Industrial Piping Many manufacturing and industrial facilities utilize CPVC for chemical transport lines due to its excellent resistance properties.

- Fire Protection Systems CPVC piping is an approved material for fire sprinkler systems, providing reliable and effective fire protection.

- Wastewater CPVC can also be utilized in wastewater systems, offering resistance to aggressive environments and chemicals.

In summary, CPVC welding rods are an essential component in the construction and maintenance of piping systems across various industries. Their unique characteristics, including chemical resistance, high-temperature tolerance, and ease of installation, make them a reliable choice for a broad range of applications. Understanding the benefits and functionality of CPVC welding rods is crucial for engineers, builders, and maintenance professionals looking to ensure safe and efficient systems in their projects.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025