Dec . 11, 2024 03:56 Back to list

Exploring the Benefits and Uses of CPVC Boards in Construction and Design

Understanding CPVC Boards Properties, Benefits, and Applications

Chlorinated Polyvinyl Chloride (CPVC) is a thermoplastic material that has gained prominence in various industries due to its excellent properties and versatility. CPVC boards, which are derived from the modification of PVC, have emerged as favorable alternatives in construction, plumbing, and various manufacturing processes. This article aims to delve into the characteristics, advantages, and applications of CPVC boards.

Properties of CPVC Boards

One of the distinguishing features of CPVC boards is their high resistance to temperature. CPVC can withstand temperatures up to 200°F (approximately 93°C), which makes it suitable for hot water applications. Additionally, CPVC boards exhibit exceptional chemical resistance, making them impervious to a wide array of corrosive substances. This attribute is particularly important in applications where exposure to chemicals is inevitable, such as in laboratories or industrial settings.

Further, CPVC boards possess excellent impact resistance and are lightweight, which simplifies handling and installation. They are also non-flammable, adding an extra layer of safety compared to other materials like wood or some metals. The low thermal conductivity of CPVC boards contributes to their energy efficiency, making them a preferred choice in construction where energy conservation is paramount.

Benefits of CPVC Boards

The myriad benefits of CPVC boards significantly contribute to their growing popularity in various sectors. One of the primary advantages is their long lifespan. CPVC boards are resistant to UV degradation, making them suitable for outdoor applications without the risk of fading or deterioration over time. This longevity translates into cost savings for consumers, as they require fewer replacements compared to other materials.

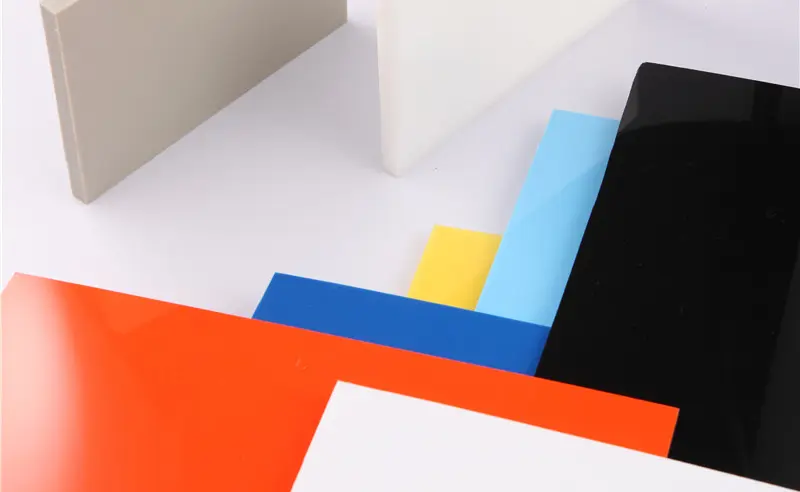

Moreover, CPVC boards are easy to fabricate and can be molded into different shapes and sizes, adding to their versatility. They can be easily cut, drilled, or glued, allowing for customization based on specific project needs. The smooth surface of CPVC boards also minimizes bacterial growth, making them a hygienic choice for applications like plumbing and food processing.

cpvc board

Another compelling benefit is the environmental impact of CPVC boards. The material is recyclable, thus aligning with sustainable practices that are becoming increasingly important in today's eco-conscious world. With minimal waste generated in their production, CPVC boards present a greener alternative compared to hardwoods or traditional plastic materials.

Applications of CPVC Boards

The applications of CPVC boards are vast and varied. In the construction industry, they are commonly used for wall panels, roofing sheets, and window frames due to their durability and weather resistance. CPVC boards can also be found in the plumbing sector, where they are utilized for pipes and fittings that transport hot and cold water.

In the realm of advertising and signage, CPVC boards serve as excellent substrates for signs and displays because of their sturdy construction and resistance to wear. They are also employed in the manufacturing of outdoor furniture and fixtures that require both aesthetics and resilience.

In laboratory settings, CPVC boards are often used in fume hoods and structural components where resistance to chemicals is critical. Their ability to withstand harsh environments makes them invaluable in ensuring safety and effectiveness in various scientific applications.

Conclusion

In summary, CPVC boards are a remarkable innovation in material science, combining impressive properties with practical applications. Their high-temperature resistance, chemical durability, and recyclability make them an excellent choice for a myriad of industries. As the demand for sustainable and efficient materials continues to rise, the use of CPVC boards is expected to expand, further establishing their role as essential components in modern construction and manufacturing processes. Whether you're an architect, contractor, or industrial manufacturer, understanding and utilizing CPVC boards can significantly enhance both operational efficiency and project outcomes.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025