Nov . 21, 2024 21:20 Back to list

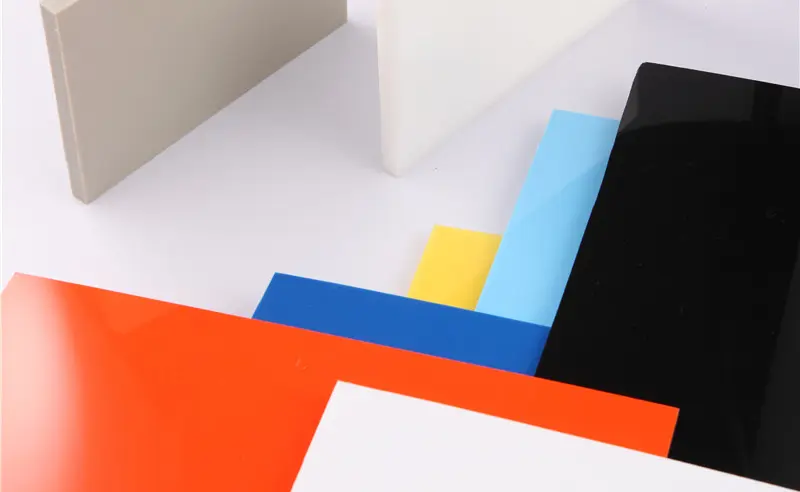

cpvc board

Understanding CPVC Board Properties, Applications, and Benefits

Chlorinated Polyvinyl Chloride (CPVC) boards have gained significant traction in various industries, thanks to their superior properties and versatility. CPVC, a thermoplastic derived from PVC through a chlorination process, possesses enhanced chemical resistance, higher thermal stability, and better mechanical strength than its unmodified counterpart, making it an ideal choice for numerous applications.

Properties of CPVC Board

One of the most outstanding properties of CPVC boards is their excellent resistance to chemicals and corrosion. This makes them highly suitable for environments where exposure to harsh chemicals is a concern, such as in chemical processing plants, wastewater treatment facilities, and laboratories. CPVC boards can withstand a broad range of substances, including acids, alkalines, and salts, thanks to their robust molecular structure.

Thermal stability is another significant advantage. CPVC can endure higher temperatures than standard PVC, typically up to 90°C (194°F), without deforming or losing its structural integrity. This quality is crucial for applications that involve hot water transportation, such as in plumbing systems and heating applications.

On the mechanical side, CPVC boards exhibit impressive impact resistance and toughness. They can endure considerable stress without cracking or breaking, which is vital in construction and industrial applications. Furthermore, CPVC boards are lightweight and easy to handle, reducing labor costs and improving installation efficiency.

Applications of CPVC Board

The versatility of CPVC boards is reflected in their wide range of applications. In the construction industry, they are utilized for plumbing and piping systems due to their excellent flow characteristics and resistance to scaling. CPVC piping systems are often preferred for both residential and commercial buildings because they provide a long-lasting solution that doesn't corrode or rust over time.

cpvc board

In addition to plumbing, CPVC boards are also extensively used in chemical storage tanks and liners. Their resilience to corrosive materials makes them a reliable option for storing hazardous substances, ensuring safety and compliance with environmental regulations.

Another notable application is in electrical insulation. CPVC boards can be used to create protective enclosures for electrical equipment, offering exceptional insulation performance. This feature is particularly important in industries such as manufacturing and construction, where electrical safety is paramount.

Benefits of Using CPVC Board

Opting for CPVC boards presents several benefits. Firstly, their longevity contributes to lower lifecycle costs. While the initial investment may be higher than some alternatives, the durability and minimal maintenance requirements lead to significant savings over time.

Additionally, CPVC boards are easy to fabricate and install. They can be cut, shaped, and joined using standard tools and methods, which simplifies the construction or installation process. This adaptability not only saves time but also minimizes waste during installation.

Environmental sustainability is yet another reason to consider CPVC boards. They are recyclable and have a lower environmental impact than many traditional materials. The production process of CPVC also adheres to various environmental regulations, making it a more eco-friendly choice in the long run.

Conclusion

In summary, CPVC boards are a remarkable material that combines durability, versatility, and chemical resistance, making them an essential component in numerous industries. Their applications span plumbing, chemical storage, and electrical insulation, underscoring their importance in modern construction and manufacturing. As industries continue to seek out materials that offer safety and efficiency, CPVC boards are poised to remain at the forefront, providing innovative solutions for a variety of challenges. Whether for residential, commercial, or industrial use, CPVC boards represent a smart investment for future-proofing projects in an ever-evolving landscape.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025