Aug . 17, 2024 10:04 Back to list

Choosing the Right Welding Rods for PVC Applications and Projects

Understanding Welding Rods for PVC - A Comprehensive Guide

PVC, or polyvinyl chloride, is a widely used thermoplastic polymer known for its versatility and durability. It is found in numerous applications, including construction, plumbing, and electrical installations. One of the essential aspects of working with PVC is the joining process, which often requires welding techniques. In this context, the choice of welding rods for PVC plays a crucial role in ensuring strong, lasting bonds. This article will explore the different types of welding rods suitable for PVC, their applications, and key considerations for effective welding.

What Are Welding Rods for PVC?

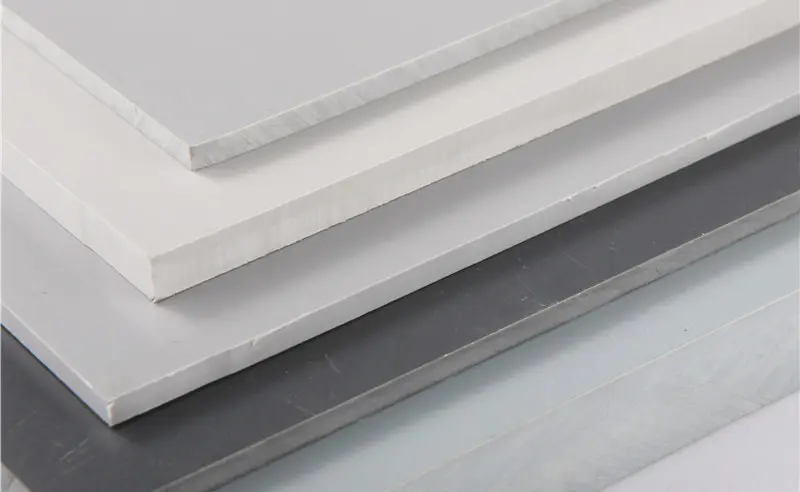

Welding rods for PVC are specifically formulated to facilitate the joining of PVC materials through processes such as extrusion or hot air welding. These rods are made from a blend of PVC compounds that match the characteristics of the base material. By using compatible welding rods, welders ensure that the bond achieved during the welding process is strong and reliable.

Types of PVC Welding Rods

1. Solid Welding Rods These rods are typically used for the manual welding of PVC pipes and sheets. They come in various diameters and colors to match the specific type of PVC being welded. Solid rods provide excellent control during the welding process as they can be easily manipulated with a handheld welding tool.

2. Extrusion Welding Rods Extrusion welding is a method that uses a continuous feed of molten material to create a bond between the PVC pieces. These rods are fed into a welding machine that heats them until they melt and combine with the base material. Extrusion rods are ideal for larger projects where speed and efficiency are critical.

3. Multipurpose Welding Rods These rods are designed to be compatible with various plastics and are often used for general-purpose welding applications. They can work well with PVC and provide flexibility in projects where different materials need to be joined.

Applications of PVC Welding Rods

PVC welding rods are used across various industries. Some noteworthy applications include

- Plumbing PVC pipes are commonly welded for drain, waste, and vent systems due to their lightweight, corrosion-resistant nature. Properly welded joints ensure leak-free connections that can withstand pressure.

welding rods for pvc

- Construction In construction, PVC sheets are often welded to create waterproof membranes, protective barriers, and custom fabrications for windows and doors

.- Aerospace and Automotive Lightweight and durable, PVC is utilized in certain components within these industries, where precise welding techniques are required to meet stringent safety standards.

Key Considerations for Effective Welding

When utilizing welding rods for PVC, there are several considerations to keep in mind

- Temperature Control PVC has a specific melting point, and exceeding this can lead to material degradation. It is essential to maintain consistent temperatures during the welding process to ensure optimal bonding.

- Surface Preparation Proper surface preparation is vital for effective welding. Clean the PVC surfaces to remove any grease, grime, or contaminants that may interfere with adhesion.

- Rod Compatibility Always choose welding rods that are compatible with the specific type of PVC you are using. Different formulations can affect the integrity of the weld.

- Technique Mastering the correct welding technique is crucial. Factors such as the speed of movement, angle of application, and pressure applied can all influence the quality of the weld.

Conclusion

Welding rods for PVC are integral to creating strong, durable joints in numerous applications. By understanding the types of rods available, their appropriate applications, and the best practices for welding, professionals and DIY enthusiasts can ensure effective and reliable results in their PVC projects. Whether for plumbing, construction, or specialized industries, the right welding rod choice can make all the difference in achieving quality craftsmanship.

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025