Oct . 15, 2024 23:20 Back to list

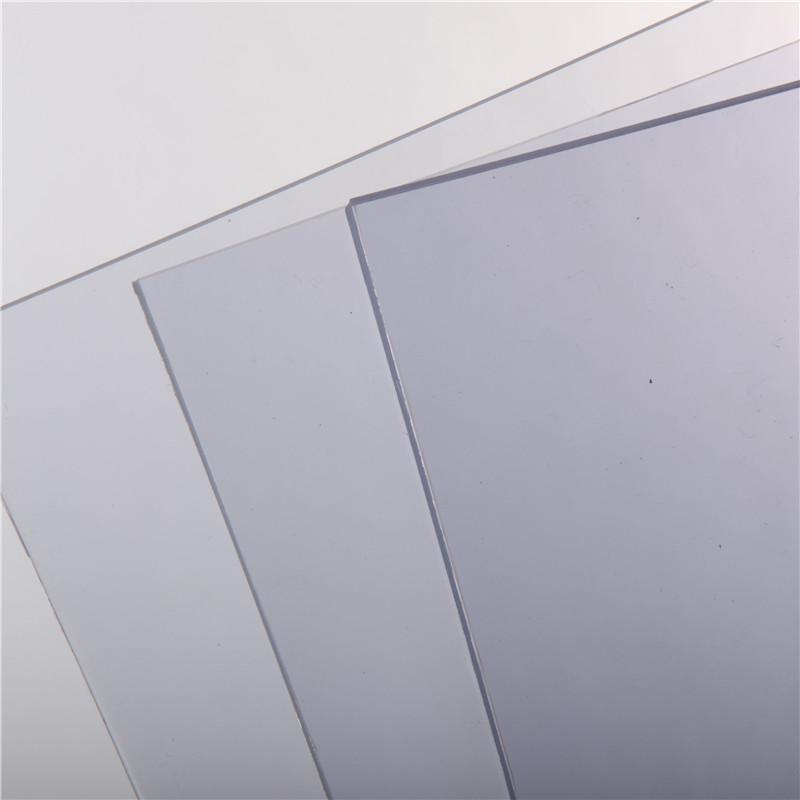

Various Thickness Options for Rigid PVC Sheets Made in China

Understanding PVC Rigid Sheets of Various Thicknesses A Comprehensive Overview

PVC (Polyvinyl Chloride) rigid sheets are widely known for their versatility and durability, making them a preferred material in various industries. In recent years, the demand for PVC rigid sheets has surged, particularly in China, driven by their applications in construction, signage, packaging, and interior design. This article aims to explore the characteristics of PVC rigid sheets in different thicknesses, their applications, and considerations for selection.

What are PVC Rigid Sheets?

PVC rigid sheets are solid thermoplastic materials formulated from polyvinyl chloride. They come in a variety of thicknesses, ranging from as thin as 0.5mm to over 20mm. The sheet's thickness significantly impacts its strength, flexibility, and applicability. The manufacturing of these sheets often involves the extrusion process, allowing for uniform thickness and smooth surfaces.

Characteristics Based on Thickness

1. Thin PVC Sheets (0.5mm to 3mm) Thin PVC sheets are lightweight and flexible, making them ideal for applications such as packaging, temporary signage, and crafting. Their ease of handling and cutting makes them suitable for DIY projects and educational purposes. However, while they are cost-effective, they are not advisable for high-stress applications, as they may be prone to bending or breaking under pressure.

2. Medium Thickness PVC Sheets (3mm to 7mm) Sheets within this range strike a balance between flexibility and durability. They are commonly used in advertising displays, furniture applications, and as protective barriers. Medium thickness PVC sheets can withstand moderate physical stress and are often preferred for both indoor and outdoor use due to their weather resistance. For instance, they are used for producing POS displays and decorative wall panels.

3. Thick PVC Sheets (7mm and above) Thick PVC rigid sheets offer enhanced strength and rigidity, making them suitable for demanding applications such as sound barriers, industrial cladding, and more substantial construction projects. Their robustness allows them to endure heavy loads and extreme weather conditions, making them ideal for outdoor signage and long-lasting installations. Additionally, they provide better insulation properties, which is advantageous in energy-efficient building projects.

china pvc rigid sheet in different thickness

Applications Across Industries

The versatility of PVC rigid sheets lends them to a wide array of applications

- Construction Used for wall coverings, ceiling tiles, and plumbing applications due to their moisture resistance and durability. - Signage Ideal for outdoor and indoor signage, providing excellent print quality and weather resistance. - Furniture Lightweight yet sturdy, PVC sheets are used in the manufacturing of office furniture and fixtures. - Packaging Due to their lightweight nature, they are also used in packaging solutions, particularly for products requiring a protective casing. Considerations for Selection

When choosing PVC rigid sheets, several factors should be considered

- Application Needs Assess the specific requirements of your project, including environmental factors and load-bearing needs. - Thickness Select the appropriate thickness based on the intended use; thinner sheets are better for general applications, while thicker sheets should be used for heavy-duty uses. - Cost Balance your budget against quality; while thinner sheets are less expensive, investing in thicker sheets can be more cost-effective in applications requiring durability. - Processing Consider how the sheets will be processed. Thinner sheets may allow easier cutting and shaping, while thicker sheets require specialized tools.

Conclusion

In summary, PVC rigid sheets are an essential material with diverse applications across various industries. Understanding the characteristics and appropriate uses for different thicknesses can significantly influence the success of your project. Whether you require thin sheets for simple applications or thick sheets for more robust structures, the versatility of PVC ensures that there is a suitable option available in the market. As demand for these materials continues to grow, particularly in countries like China, innovations in production and application methods are likely to further enhance their utility and efficiency.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025