Nov . 05, 2024 17:16 Back to list

black hdpe pipe

Understanding Black HDPE Pipes Applications, Benefits, and Installation

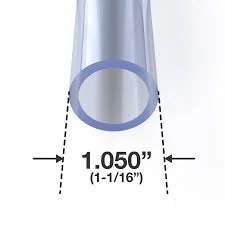

High-Density Polyethylene (HDPE) pipes have gained significant popularity in various industries due to their outstanding properties and versatility. Among these, black HDPE pipes stand out as a common choice for many applications. This article will delve into the characteristics, benefits, uses, and installation practices associated with black HDPE pipes.

What is HDPE and the Significance of Black Color?

HDPE is a thermoplastic polymer made from petroleum. It is known for its high strength-to-density ratio, making it a durable option for various applications. The black color of HDPE pipes is not merely aesthetic; it is often achieved through the incorporation of carbon black, which serves several crucial purposes. One of the primary benefits of carbon black is its ability to protect the pipe from harmful UV radiation. This is particularly important for applications where the pipes may be exposed to sunlight, ensuring their longevity and reducing degradation over time.

Key Benefits of Black HDPE Pipes

1. Durability Black HDPE pipes are resistant to a wide range of chemicals, making them suitable for transporting various liquids without risk of corrosion. They can withstand extreme temperatures, and their robust nature allows them to resist impact damage, making them ideal for harsh environments.

2. Flexibility Unlike some traditional piping materials, HDPE pipes are flexible, which means they can be installed in a variety of configurations. This flexibility allows for considerable savings in installation time and reduces the need for fittings.

3. Lightweight Black HDPE pipes are significantly lighter than traditional materials like concrete or steel. This characteristic makes them easier to transport and handle during installation, resulting in lower labor costs and simplified logistics.

4. Reduced Friction The smooth inner surface of HDPE pipes minimizes friction, which enhances flow rates and reduces energy costs associated with pumping fluids through the pipes.

5. Sustainability HDPE pipes can be recycled, contributing to environmental sustainability. Many manufacturers produce HDPE from recycled materials, thereby reducing the carbon footprint associated with their production.

Common Applications of Black HDPE Pipes

Black HDPE pipes are utilized in numerous sectors, reflecting their adaptability. Some of the most common applications include

black hdpe pipe

- Water Distribution Black HDPE pipes are extensively used in municipal water supply systems due to their corrosion resistance and flexibility. They ensure the safe transportation of potable water while minimizing leakage.

- Irrigation Systems Agriculture relies heavily on efficient irrigation systems, and black HDPE pipes are frequently employed in drip and sprinkler systems. Their durability and UV resistance make them ideal for outdoor applications.

- Gas Distribution These pipes are also used for the transportation of natural gas and other gases. Their strength and resistance to external impacts are essential for ensuring safety in gas distribution networks.

- Industrial Applications Many industries rely on black HDPE pipes for various chemical transportation needs. Their resistance to a broad spectrum of chemicals makes them versatile in industrial settings.

Installation Best Practices

Proper installation is crucial to maximizing the benefits of black HDPE pipes. Here are some key practices to consider

1. Site Preparation Before installation, ensure that the site is properly prepared, with a clearance from rocks or debris that could damage the pipe.

2. Trenching Digging trenches must align with local regulations, ensuring sufficient depth and width to accommodate the pipes while allowing for backfill.

3. Jointing Methods Use appropriate jointing techniques, such as fusion welding, to ensure that the joints are as strong as the pipe itself. This helps maintain the integrity of the system.

4. Testing Once installed, conduct pressure tests to ensure there are no leaks. Regular inspections should also be scheduled to monitor the condition of the pipes over time.

Conclusion

Black HDPE pipes offer a reliable and versatile solution across various industries. Their durability, flexibility, and resistance to environmental factors make them an excellent choice for water, gas, and chemical transportation. As industries continue to evolve, the demand for HDPE pipes, particularly black ones, will likely increase, underlining their significance in modern infrastructure development. By adhering to best practices in installation and maintenance, users can ensure these pipes deliver their full array of benefits for years to come.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025