नोभ . 24, 2024 18:27 Back to list

hdpe pipe fittings

Understanding HDPE Pipe Fittings A Comprehensive Guide

High-Density Polyethylene (HDPE) pipe fittings have become increasingly popular in various industries due to their durability, flexibility, and resistance to corrosion. This article will delve into the characteristics, types, advantages, and applications of HDPE pipe fittings.

What is HDPE?

HDPE is a thermoplastic polymer made from petroleum. It is known for its high strength-to-density ratio and is used in a wide range of applications, including the manufacturing of bottles, containers, and, notably, piping systems. One of the main reasons for HDPE's popularity in piping is its resistance to a variety of chemicals and its ability to withstand harsh environmental conditions.

Characteristics of HDPE Pipe Fittings

HDPE pipe fittings are designed to connect various sections of HDPE pipes or to connect pipes to valves and other equipment. Here are some key characteristics of HDPE pipe fittings

1. Durability HDPE fittings are resistant to cracking and can withstand physical stress, making them suitable for high-pressure applications.

2. Corrosion Resistance Unlike metal fittings, HDPE does not corrode, which extends the lifespan of the fitting and reduces maintenance costs.

3. Chemical Resistance HDPE can handle a wide range of chemicals, making it ideal for industrial applications.

4. Flexibility The flexibility of HDPE allows it to be installed in challenging terrains without the risk of damage.

5. Lightweight HDPE fittings are much lighter than traditional materials like steel or cast iron, simplifying transportation and installation.

6. Low Friction The smooth interior of HDPE fittings reduces friction, resulting in lower energy costs.

Types of HDPE Pipe Fittings

HDPE pipe fittings come in various shapes and sizes to accommodate different applications. The most common types include

1. Elbows Used to change the direction of the pipe layout, elbows are available in various angles, such as 45 degrees and 90 degrees.

2. Tees These fittings are used to create branching connections in the pipeline, allowing for a flow of fluid in different directions.

3. Reducers Designed to connect pipes of different diameters, reducers help manage flow rates and pressure.

4. Caps and Plugs These fittings close the ends of pipes. Caps are used for external openings, while plugs are for internal closures.

hdpe pipe fittings

5. Flanges Used to connect pipes to other equipment, flanges allow for easy disassembly and maintenance.

6. Couplings These fittings connect two sections of pipe, usually of the same diameter.

Advantages of Using HDPE Pipe Fittings

The advantages of using HDPE pipe fittings are numerous

1. Cost-Effectiveness While the initial cost may be comparable to other materials, the longevity and low maintenance of HDPE result in lower overall costs.

2. Environmental Impact HDPE is recyclable, making it a more environmentally friendly option than other materials that contribute to landfill waste.

3. Installation Efficiency The lightweight nature of HDPE fittings makes them easier to handle and quicker to install, reducing labor costs.

4. Leak-Free Joints When properly fused, HDPE fittings create strong, leak-free joints, reducing the risk of leaks that can lead to costly repairs and environmental damage.

Applications of HDPE Pipe Fittings

HDPE pipe fittings are widely used across various sectors, including

1. Water Supply Systems HDPE fittings are often used in municipal water supply systems because they do not rust or corrode.

2. Wastewater Management The chemical resistance of HDPE makes it ideal for handling sewage and other waste materials.

3. Irrigation Systems In agriculture, HDPE fittings are used in drip and sprinkler irrigation systems due to their durability and efficiency.

4. Gas Distribution HDPE is also employed in gas distribution networks where safety and reliability are critical.

5. Industrial Applications Various industries use HDPE pipe fittings for transporting chemicals and other materials due to their robustness.

Conclusion

In conclusion, HDPE pipe fittings offer significant advantages in terms of durability, cost-effectiveness, and versatility across numerous applications. As industries continue to seek sustainable and efficient solutions, the use of HDPE pipe fittings is likely to grow, making them a vital component in modern piping systems. Understanding their characteristics and applications can help consumers and professionals make informed decisions for their specific needs.

-

Clear PVC Pipe & Rigid Sheets - High Transparency & Durable Solutions

NewsMay.20,2025

-

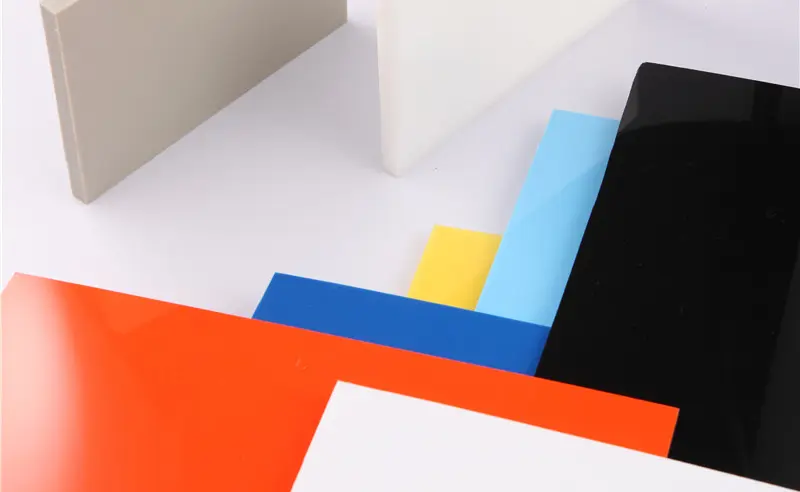

HDPE, PVC & PP Plates Durable, Chemical-Resistant Sheet Solutions

NewsMay.20,2025

-

CPVC & PVC Welding Rods - High-Temperature Resistant & Durable Solutions

NewsMay.19,2025

-

Durable PVC Water Supply Pipe Corrosion-Resistant & Lightweight

NewsMay.19,2025

-

PP Panels Durable PVC & CPVC Panel Solutions for Modern Walls

NewsMay.19,2025

-

Efficient PVC Pipe Drip Irrigation Systems - Save Water & Costs

NewsMay.18,2025