जानेवारी . 14, 2025 10:21 Back to list

PP welding rod

Round polyethylene (PE) welding rods have emerged as an indispensable component in the world of plastic fabrication, owing to their robust properties and adaptability in various applications. With roots tracing back to the advancement of polymer science, PE welding rods are now at the forefront of modern manufacturing, offering both novices and industry veterans an accessible pathway to quality craftsmanship.

In addition to technical skills, the credibility of the source from which the rods are procured cannot be understated. Ensuring that the welding rods meet industry standards and come from reputable manufacturers can significantly impact the quality of the welds. Trusted suppliers will provide material certifications and maintain consistent quality, which translates directly to the reliability of the finished product. To bolster trustworthiness and authority in using round PE welding rods, personal experience accompanied by ongoing training plays a crucial role. Engaging with professional workshops, learning about new welding technologies, and hands-on experimentation are essential in mastering this craft. Sharing experiences with peers through professional networks or forums can also provide fresh insights and validate one's expertise in this specialized field. Investing in quality welding equipment is another factor that enhances the experience with PE welding rods. Tools that offer precise temperature control and ergonomics facilitate an efficient and effective welding process. Moreover, using advanced equipment reduces the margin for error, thus increasing the trust in the welded products' performance. Ultimately, round PE welding rods remain a cornerstone for those seeking to transform plastic materials into durable, reliable products. Their versatility, when coupled with a thorough understanding of material science and proper technique, allows for unparalleled craftsmanship. As technology progresses and new innovations arise, the mastery of using these rods continues to be a testament to the blend of skill, authority, and trust in the realm of plastic welding.

In addition to technical skills, the credibility of the source from which the rods are procured cannot be understated. Ensuring that the welding rods meet industry standards and come from reputable manufacturers can significantly impact the quality of the welds. Trusted suppliers will provide material certifications and maintain consistent quality, which translates directly to the reliability of the finished product. To bolster trustworthiness and authority in using round PE welding rods, personal experience accompanied by ongoing training plays a crucial role. Engaging with professional workshops, learning about new welding technologies, and hands-on experimentation are essential in mastering this craft. Sharing experiences with peers through professional networks or forums can also provide fresh insights and validate one's expertise in this specialized field. Investing in quality welding equipment is another factor that enhances the experience with PE welding rods. Tools that offer precise temperature control and ergonomics facilitate an efficient and effective welding process. Moreover, using advanced equipment reduces the margin for error, thus increasing the trust in the welded products' performance. Ultimately, round PE welding rods remain a cornerstone for those seeking to transform plastic materials into durable, reliable products. Their versatility, when coupled with a thorough understanding of material science and proper technique, allows for unparalleled craftsmanship. As technology progresses and new innovations arise, the mastery of using these rods continues to be a testament to the blend of skill, authority, and trust in the realm of plastic welding.

Share:

Next:

Latest news

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025

-

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

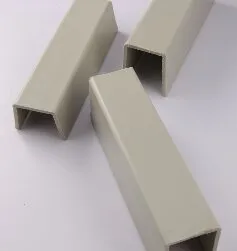

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025