Oct . 22, 2024 01:42 Back to list

Understanding the Benefits and Applications of CPVC Board in Construction

The Versatile Applications of CPVC Board

Chlorinated Polyvinyl Chloride (CPVC) boards have emerged as a valuable material in various industries due to their excellent properties and versatility. As a rigid thermoplastic, CPVC displays remarkable resistance to high temperatures, corrosion, and chemicals, making it an ideal choice for numerous applications. In this article, we will explore the significance of CPVC boards, their benefits, and their extensive usage across different sectors.

What is CPVC?

CPVC is a polymer that is produced by chlorinating PVC resin. This chemistry endows CPVC with superior thermal stability and fire resistance as compared to standard PVC. While PVC can typically withstand temperatures up to 60°C (140°F), CPVC can handle temperatures exceeding 90°C (194°F) without degrading. These characteristics make CPVC boards particularly useful in environments where heat and chemical exposure are issues.

Benefits of CPVC Boards

1. Chemical Resistance One of the standout features of CPVC boards is their resistance to a wide range of chemicals including acids, bases, and salts. This makes them highly suitable for use in chemical processing plants and laboratories where exposure to hazardous substances is commonplace.

2. Thermal Stability CPVC's ability to maintain integrity and performance at elevated temperatures further enhances its appeal. Applications involving hot water or steam systems benefit significantly from this property, which ensures long-term reliability and safety.

3. Lightweight and Durable CPVC boards are considerably lighter than traditional materials like wood or metal. This characteristic not only reduces shipping and handling costs but also simplifies installation processes. Additionally, CPVC is durable and resistant to shocks, making it suitable for heavy-duty applications.

4. Ease of Fabrication CPVC boards can be easily cut, shaped, and joined through various processes, including welding, adhesive bonding, and mechanical fastening. This adaptability allows for the creation of custom solutions tailored to specific project requirements.

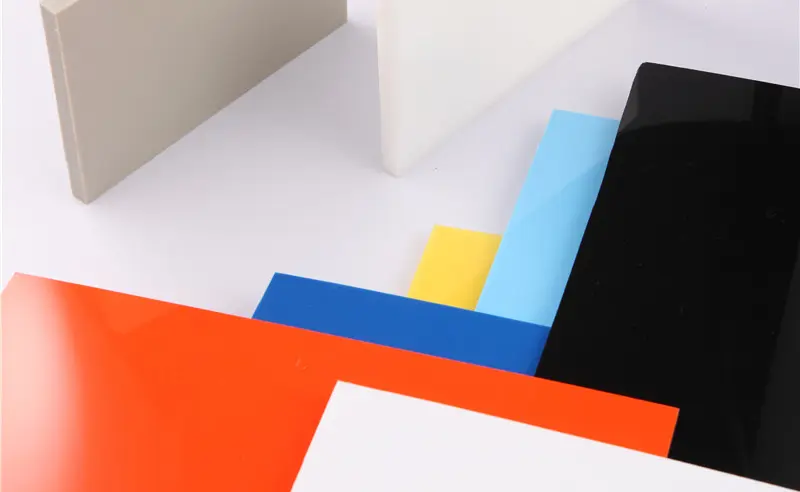

cpvc board

5. Cost-Effectiveness Despite their high-quality performance, CPVC boards are often competitively priced compared to alternatives like metals or specialty plastics. Their low maintenance requirements and long lifespan contribute to overall cost savings for businesses.

Applications of CPVC Boards

1. Construction and Building CPVC boards are increasingly used in construction for applications such as roofing, interior wall panels, and plumbing systems. Their resistance to moisture and chemicals makes them ideal for environments such as bathrooms, kitchens, and laboratories.

2. Chemical Processing In industries that require safe handling of corrosive materials, CPVC boards offer significant advantages. They are commonly utilized in the construction of containment structures, piping systems, and storage tanks where durability against harsh chemical exposure is paramount.

3. Electrical Sector Due to their excellent insulating properties, CPVC boards are often employed in electrical applications. They are used as protective covers for wiring and conduits, safe-guarding them against environmental factors.

4. Marine Industry The marine sector also benefits from CPVC's resistance to saltwater corrosion. CPVC boards are used in boat building and for components exposed to marine environments, helping to prolong product lifespan while minimizing maintenance costs.

5. HVAC Systems CPVC's thermal stability and chemical resistance make it suitable for heating, ventilation, and air conditioning systems. It is often used in ductwork, which must withstand a range of temperatures and possible exposure to chemicals.

Conclusion

In conclusion, CPVC boards stand out as an efficient, durable, and versatile material that proves useful across various industries. Their unique properties allow them to perform effectively in demanding environments while offering cost benefits that make them attractive choices for businesses. As the demand for innovative building materials continues to grow, the applications of CPVC are likely to expand further, making it a key player in the future of construction and manufacturing. Whether it's in construction, chemical processing, or electrical applications, CPVC boards are proving to be an indispensable resource that meets modern-day challenges head-on.

-

PVC Transparent Sheet Roll - Durable & Flexible PVC Plastic Sheet Roll for Industrial & Home Use

NewsJun.24,2025

-

High-Quality PVC PPR Pipes and Fittings Durable ERA PPR Solutions

NewsJun.10,2025

-

High-Quality Large HDPE Sheets & Large Diameter PVC Pipe Durable Large PVC Pipe Supplier

NewsJun.10,2025

-

High Density Polyethylene Cutting Board - Durable & Food Safe

NewsJun.09,2025

-

3 Inch PVC Pipe for Durable Irrigation Affordable & Reliable

NewsJun.09,2025

-

Premium PPR Plastic Water Pipe Fittings - Durable & Leak-Free

NewsJun.09,2025