Feb . 10, 2025 10:27 Back to list

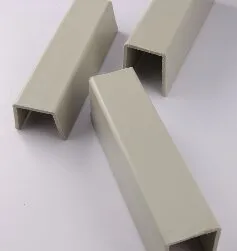

UPVC drainage and irrigation pipe

Electrical PVC pipes have become indispensable in the modern construction and electrical industries. Offering a seamless combination of durability, flexibility, and cost-effectiveness, these pipes have carved out a niche for themselves. Having worked in the industry for more than a decade, I can assert that understanding the nuances of PVC pipes is essential for anyone looking to make informed decisions about electrical installations.

Trustworthiness in using electrical PVC pipes is further reinforced through rigorous testing and adherence to safety standards established by institutions such as the National Electrical Manufacturers Association (NEMA). These standards ensure that the pipes can withstand significant stress and environmental variations, providing peace of mind to consumers and professionals alike. Additionally, the non-conductive properties of PVC reduce the risk of electric shock, thereby offering an added layer of protection that users can rely on. Real-world experiences underscore the multifaceted applications of electrical PVC pipes, from underground conduit systems to above-ground frameworks, making them versatile components in diverse environmental conditions. This adaptability is a testament to the material’s engineering prowess, catering to the intricate needs of urban infrastructure and rural development projects effectively. In conclusion, the strategic use of electrical PVC pipes in construction not only reflects a deep understanding of material science but also a commitment to safety, efficiency, and cost management. As the industry continues to evolve with technological advancements, the role of PVC pipes is likely to expand, offering innovative solutions that drive sustainable development. Therefore, investing in quality electrical PVC pipes signifies not just a purchase, but a step towards enduring reliability and progressive engineering excellence.

Trustworthiness in using electrical PVC pipes is further reinforced through rigorous testing and adherence to safety standards established by institutions such as the National Electrical Manufacturers Association (NEMA). These standards ensure that the pipes can withstand significant stress and environmental variations, providing peace of mind to consumers and professionals alike. Additionally, the non-conductive properties of PVC reduce the risk of electric shock, thereby offering an added layer of protection that users can rely on. Real-world experiences underscore the multifaceted applications of electrical PVC pipes, from underground conduit systems to above-ground frameworks, making them versatile components in diverse environmental conditions. This adaptability is a testament to the material’s engineering prowess, catering to the intricate needs of urban infrastructure and rural development projects effectively. In conclusion, the strategic use of electrical PVC pipes in construction not only reflects a deep understanding of material science but also a commitment to safety, efficiency, and cost management. As the industry continues to evolve with technological advancements, the role of PVC pipes is likely to expand, offering innovative solutions that drive sustainable development. Therefore, investing in quality electrical PVC pipes signifies not just a purchase, but a step towards enduring reliability and progressive engineering excellence.

Share:

Next:

Latest news

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025