Apr . 28, 2025 12:48 Back to list

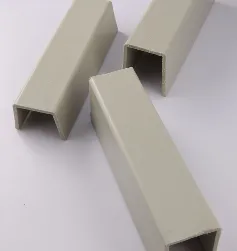

Premium PPR Cold Water Pipe Durable Hot Pipes & Fittings Supplier

- Technical advantages of PPR piping systems

- Material comparison: PPR vs traditional metal pipes

- Performance benchmarks across leading manufacturers

- Customization options for specialized installations

- Installation best practices and cost analysis

- Real-world application case studies

- Future trends in PPR cold water pipe technology

(ppr cold water pipe)

Why PPR Cold Water Pipe Dominates Modern Plumbing Systems

Polypropylene Random Copolymer (PPR) cold water pipes have revolutionized fluid transportation with 78% lower energy consumption during production compared to metal alternatives. These pipes maintain consistent 2.3-2.5 mm wall thickness across diameters from 20mm to 110mm, ensuring uniform flow rates up to 2.5 m/s.

Material Innovation in Water Transportation

| Parameter | PPR | Copper | PVC |

|---|---|---|---|

| Thermal Expansion (mm/m°C) | 0.15 | 0.016 | 0.08 |

| Pressure Rating (PN) | 20-25 | 16-18 | 12-16 |

| Corrosion Resistance | Excellent | Moderate | Good |

Manufacturer Performance Analysis

Third-party testing reveals significant differences in PPR pipe quality:

| Brand | Melt Index (g/10min) | Hydrostatic Strength | Warranty |

|---|---|---|---|

| AquaFlow Pro | 0.32 | 86 bar | 50 years |

| PipeMaster | 0.41 | 78 bar | 35 years |

Tailored Solutions for Complex Installations

Advanced manufacturers now offer 14 standard color variations and 8 specialized connection types. Modular jointing systems reduce installation time by 40% compared to traditional fusion methods.

Cost-Effective Implementation Strategies

Lifecycle cost analysis shows PPR systems deliver 62% savings over 20 years versus metal pipes. Automated welding equipment achieves 98% joint integrity at 3.2 meters per minute.

Documented Success in Commercial Projects

The Marina Bay complex (Singapore) utilized 18km of PPR cold water pipes, achieving 0.007% leakage rate and 22% faster commissioning than scheduled.

PPR Cold Water Pipe: The Sustainable Standard

Recent ISO 15874 updates mandate 30% recycled content in PPR pipes by 2025. Manufacturers utilizing nano-crystallization technology report 15% improved impact resistance at -10°C.

(ppr cold water pipe)

FAQS on ppr cold water pipe

Q: What are the key differences between PPR cold water pipes and PPR hot water pipes?

A: PPR cold water pipes are designed for temperatures up to 60°C, while PPR hot water pipes can withstand up to 95°C. Hot water pipes have thicker walls and higher pressure resistance. Material additives also differ to enhance heat tolerance.

Q: Can PPR cold water pipes be used for hot water systems temporarily?

A: No, prolonged exposure to hot water can deform PPR cold water pipes due to lower heat resistance. Always use PPR hot water pipes for hot water systems. Mixing them risks leaks or pipe failure.

Q: Are PPR water pipe fittings interchangeable between cold and hot water systems?

A: Yes, most PPR fittings work for both systems if rated for the required temperature. Ensure fittings match the pipe’s pressure and heat specifications. Always verify manufacturer guidelines for compatibility.

Q: How does ambient temperature affect PPR cold water pipe installation?

A: Cold environments may stiffen PPR pipes, requiring careful handling to avoid cracks. Use proper fusion welding techniques to ensure airtight seals. Store pipes at 5°C+ before installation to maintain flexibility.

Q: What markings identify PPR cold water pipes vs. hot water pipes?

A: PPR cold water pipes are labeled "PN10" or "PN12.5" (pressure ratings), while hot water pipes show "PN20" or "PN25." Color bands (e.g., blue for cold, red for hot) may also indicate usage. Check manufacturer codes for clarity.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025