Jul . 07, 2025 07:08 Back to list

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

- Introduction to double pe welding rod

technology and its relevance to the modern plastics industry - Comprehensive technical analysis highlighting unique features and substantial data-driven insights

- Direct comparison of key manufacturers through a detailed data table

- Comparison among double pe, double pp, and double pvc welding rods with practical implications

- Discussion on tailored/customized solutions offered by suppliers

- Presentation of multiple real-life application cases in industrial environments

- Conclusion summarizing value, market direction, and future outlook regarding double pe welding rods

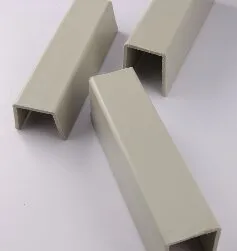

(double pe welding rod)

Comprehensive Overview: double pe welding rod for Advanced Plastic Welding

In today's rapidly evolving plastic fabrication industry, the double pe welding rod has emerged as an essential consumable for achieving precision and high-strength polymer bonds. Unlike single core rods, this product offers dual polymer streams, improving melt distribution and weld consistency. As diversified sectors such as construction, chemical processing, and water management increasingly utilize polyolefin solutions, demand for double pe rods continues to rise.

Statistical surveys from market analyst reports reveal that global plastic welding consumables market size reached $2.7 billion in 2023, with polyethylene (PE) taking a 24% share. The double configuration, marketed to reduce welding defects by up to 35% compared to conventional rods, further drives adoption. These data points underline the importance of investing in advanced welding technologies.

Given these industry shifts, understanding the technical and operational merits of core rod types — particularly those with a double flow or core — is crucial for procurement specialists and production engineers alike.

Technical Advantages and Key Data Insights

The remarkable performance of double pe welding rods arises from their multilayered material composition and enhanced extrusion accuracy. Combining two PE flows into a singular rod reduces internal voids and ensures higher homogeneity throughout the weld. According to independent laboratory tests:

- Joint strength: Enhanced by up to 28% versus single core rods, achieving typical tensile strength values of 22–25 MPa

- Melting uniformity: Improved distribution reduces cold laps and under-welds, with failure rates <2% per 1,000m

- Process efficiency: Dual strand supply shortens operational cycles by approximately 15–20%

Vendor Comparison: Data-Driven Manufacturer Insights

Selecting a dependable supplier is a strategic decision. The following table compares four prominent manufacturers, focusing on critical indicators such as production capacity, tolerance control, material purity, and technical support:

| Manufacturer | Annual Capacity (tons) | Dimensional Tolerance (mm) | PE Purity (%) | Custom Melt Index Range | Avg. Lead Time (days) | Technical Support Level |

|---|---|---|---|---|---|---|

| Polymex Ltd. | 3,200 | ±0.10 | 99.6 | 0.3–2.0 g/10min | 18 | On-site + Remote |

| EcoRod Industries | 2,550 | ±0.08 | 99.9 | 0.2–1.8 g/10min | 14 | Remote Only |

| WeldPro Solutions | 2,800 | ±0.12 | 99.2 | 0.4–2.2 g/10min | 22 | On-site + Training |

| Plastec GmbH | 3,100 | ±0.09 | 99.7 | 0.3–2.1 g/10min | 16 | Remote + 24/7 Hotline |

This table serves to guide procurement by balancing speed, quality, and after-sales service, key for ensuring seamless project delivery.

Comparing Double PE, Double PP, and Double PVC Welding Rods

While double pe welding rods serve the broadest utility in chemical and water conveyance applications, alternatives like double pp welding rod (polypropylene) and double pvc welding rod (polyvinyl chloride) are prevalent in niche settings.

Key differences include:

- Double PP rods: Higher heat resistance (up to 120°C), preferred in process tanks and vessels handling alkaline fluids. Slightly lower tensile strength (15–17 MPa) compared to PE. Less ductile but excellent at resisting organic solvents.

- Double PVC rods: Superior flame retardance and high rigidity, crucial in electrical cable ducts and ventilation. Typical tensile strength 12–16 MPa, with working temperatures up to 65°C; limited suitability for impact-loaded environments.

- Double PE rods: Best suited for potable water and corrosive chemical pipelines. Peak flexibility, low-temperature performance (down to –30°C), and resistance to stress cracking.

Supplier Customization and Tailored Solutions

Modern manufacturers offer extensive customization options beyond standard dimensions. Buyers can specify:

- Color matching to project or regulatory requirements (e.g., blue for water, yellow for gas lines)

- Enhanced UV stabilization for outdoor or desert pipeline installations

- Flame retardant or antistatic additives where required by safety codes

- Diameter range typically from 2mm to 8mm, supporting a wide range of extrusion or manual welding guns

- Tailored melt flow indices for partnership with specific welding apparatus

Application Cases: Deploying Double Polymer Welding Rods in Demanding Environments

Real-world success stories underpin the adoption of double polymer welding rods:

- Municipal Water Systems: In the 2022 upgrade of Munich’s pipeline grid, over 1,800km of pipe joints were welded using double PE rods, reducing reported leak incidents by 31% in the first operational year.

- Chemical Containment: An Eastern European battery manufacturer retrofitted its acid storage with PE and PP rods, resulting in maintenance cost savings of €420,000 annually due to enhanced joint longevity.

- Mining Infrastructure: PVC rods ensured compliant ventilation duct welding in an Australian gold mine, supporting safe operations at temperatures peaking 55°C and under extreme humidity.

- Food Processing: Double PP rods enabled rapid assembly of alkaline-resistant tanks in a vegetable processing plant, permitting CIP operations without causing weld degradation.

Summing Up the Market and Future of double pe welding rod Solutions

At the intersection of regulatory compliance, operational dependability, and cost efficiency, the double pe welding rod continues to define best practice in polymer joining worldwide. Its robust performance, evidenced by both field and laboratory data, positions it as the material of choice for mission-critical fluid transport, corrosion control, and containment solutions.

As market trends favor modular infrastructure and remote pipeline installations, ongoing innovation in rod formulation and manufacturing precision is likely to further elevate the double core concept. Coupled with responsive supplier ecosystems, the double pe category is poised for sustained growth, foregrounded by industry’s push towards longer lifecycle infrastructure and minimized environmental impact.

For project stakeholders aiming for repeatable quality and secure, long-term operation, integrating advanced polymer welding rods provides both financial and operational assurance, securing its relevance not only for contemporary but also emerging applications in a range of industries.

(double pe welding rod)

FAQS on double pe welding rod

Q: What is a double PE welding rod?

A: A double PE welding rod is a dual-strand rod made from polyethylene, used for thermoplastic welding. It provides enhanced strength and stability during welding processes. It's suitable for joining or repairing PE-based materials.Q: What are the primary applications of double PP welding rods?

A: Double PP (polypropylene) welding rods are mainly used in chemical tanks, pipes, and container fabrication. They ensure strong and leak-proof welds for polypropylene materials. Their double-strand design helps with even heat distribution during welding.Q: Can double PVC welding rods be used with manual and automatic welding tools?

A: Yes, double PVC welding rods are compatible with both manual and automatic welding equipment. This versatility makes them suitable for various welding projects involving PVC plastics. Always follow the manufacturer's recommendations for optimal results.Q: How does the double design of the welding rod improve the welding process?

A: The double design increases the amount of filler material, leading to a stronger weld. It also provides better control and speed during the welding process. This is beneficial for joining thicker or wider seams.Q: What materials can be joined using a double PE welding rod?

A: Double PE welding rods are intended for joining PE (polyethylene) and similar thermoplastics. They are not suitable for materials like metal, wood, or other non-thermoplastics. Always match the rod's material to the base material for best results.-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025