Jan . 09, 2025 12:27 Back to list

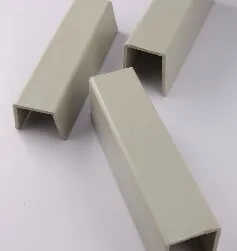

hdpe sheet

High-density polyethylene (HDPE) sheets have revolutionized various industries with their impressive properties and wide-ranging applications. This strong, durable material has become an industry leader due to its exceptional characteristics, making it a favored choice for a variety of purposes. When selecting materials for your next project, understanding the advantages and applications of HDPE sheets can provide you with insight into this versatile product.

In food and beverage industries, the non-toxic nature of HDPE makes it suitable for direct contact with food. Cutting boards and food processing equipment often feature HDPE surfaces due to their ease of cleaning and lack of porosity, which minimizes bacterial cultivation. Furthermore, HDPE's chemical resistance ensures that it does not react with the food products, maintaining food safety standards. When it comes to aesthetics, HDPE sheets do not fall behind. Available in a variety of colors and finishes, they offer customizable options to fit specific design requirements. Customization does not compromise performance; whether applied in signage or retail displays, HDPE maintains its durability and resistance, resulting in long-lasting installations. Aligning with the requirements of precision engineering, HDPE sheets can be drilled, welded, and machined to exact specifications. This adaptability further enhances their usability across different sectors, solidifying their status as a go-to material for engineers and manufacturers seeking reliability and versatility. In conclusion, HDPE sheets embody a perfect blend of durability, versatility, and cost-effectiveness. Their manifold applications across various industries underscore their indispensable role in modern solutions. By choosing HDPE sheets, businesses not only gain a material that meets rigorous demands but also contribute to sustainable practices, leveraging a product that ensures long-term performance and ecological responsibility.

In food and beverage industries, the non-toxic nature of HDPE makes it suitable for direct contact with food. Cutting boards and food processing equipment often feature HDPE surfaces due to their ease of cleaning and lack of porosity, which minimizes bacterial cultivation. Furthermore, HDPE's chemical resistance ensures that it does not react with the food products, maintaining food safety standards. When it comes to aesthetics, HDPE sheets do not fall behind. Available in a variety of colors and finishes, they offer customizable options to fit specific design requirements. Customization does not compromise performance; whether applied in signage or retail displays, HDPE maintains its durability and resistance, resulting in long-lasting installations. Aligning with the requirements of precision engineering, HDPE sheets can be drilled, welded, and machined to exact specifications. This adaptability further enhances their usability across different sectors, solidifying their status as a go-to material for engineers and manufacturers seeking reliability and versatility. In conclusion, HDPE sheets embody a perfect blend of durability, versatility, and cost-effectiveness. Their manifold applications across various industries underscore their indispensable role in modern solutions. By choosing HDPE sheets, businesses not only gain a material that meets rigorous demands but also contribute to sustainable practices, leveraging a product that ensures long-term performance and ecological responsibility.

Share:

Next:

Latest news

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025

-

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025