تشرینی دووەم . 11, 2024 03:02 Back to list

HDPE Conduit Pipe Benefits and Applications in Modern Infrastructure Solutions

Understanding HDPE Conduit Pipe An Essential Component in Modern Infrastructure

High-Density Polyethylene (HDPE) conduit pipes have become an integral part of modern infrastructure, especially in the fields of telecommunications, electrical work, and various utility services. Known for their durability, flexibility, and resistance to various environmental factors, HDPE conduit pipes are increasingly being favored over traditional piping materials such as metal or PVC.

What is HDPE?

HDPE, or high-density polyethylene, is a thermoplastic polymer made from petrochemical feedstocks. It is characterized by its high strength-to-density ratio, which makes it an ideal option for various applications. HDPE is widely used for making containers, bottles, toys, and most relevantly, conduit pipes.

Advantages of HDPE Conduit Pipe

The benefits of using HDPE conduit pipe are numerous. One of the primary advantages is its resistance to corrosion and chemical damage. Unlike metal pipes that can rust or corrode over time, HDPE pipes remain intact and maintain their structural integrity when exposed to different environments. This feature makes them particularly effective for underground installation, where they are subjected to moisture and various soil chemicals.

Additionally, HDPE conduit pipes are lightweight and easier to handle than traditional materials, which can significantly reduce labor costs during installation. Their flexibility allows for curved or bent installations without needing additional fittings. This can simplify the installation process and save on both time and budget.

Another notable benefit is HDPE's smooth interior surface, which reduces friction and allows for efficient flow of electrical cables and other utilities. This is especially important in telecommunications, where maximizing signal integrity is crucial. The material also has a low thermal conductivity, minimizing the risk of heat transfer, which can be a concern with electrical installations.

hdpe conduit pipe

Applications

HDPE conduit pipes are used across various sectors. In telecommunications, they often serve as protective channels for fiber optic cables. These conduits allow for the safe burial of cables, shielding them from environmental elements and physical damage. In electrical installations, HDPE pipes provide a safe route for electrical wiring, protecting it from moisture and other potential hazards.

Moreover, HDPE conduits are commonly employed in water and gas distribution. While these applications often use different grades of polyethylene, the common characteristics of HDPE – reliability and resistance – make it a go-to choice. Its compatibility with different installation methods, including trenching and boring, further strengthens its position as the preferred conduit material.

Environmental Considerations

One of the standout features of HDPE is its environmental sustainability. Unlike many plastics that can release harmful chemicals during production and disposal, HDPE is recyclable and can be repurposed into new products. This aligns with growing global efforts towards sustainability and reducing plastic waste. Various manufacturers comply with ISO certifications and environmental standards, ensuring that their operations minimize ecological impact.

Conclusion

In conclusion, HDPE conduit pipes are a vital component in the ecosystem of modern utilities and telecommunications. Their durability, flexibility, and resistance to environmental factors position them as a superior option compared to traditional materials. As society continues to prioritize sustainable practices, the usage of HDPE conduit pipes is likely to expand further. Whether for electrical installations, fiber optic cables, or utility services, HDPE is undoubtedly a key player that supports the infrastructure of the future. By choosing HDPE, industries are not only investing in quality and reliability but also contributing to a more sustainable world.

-

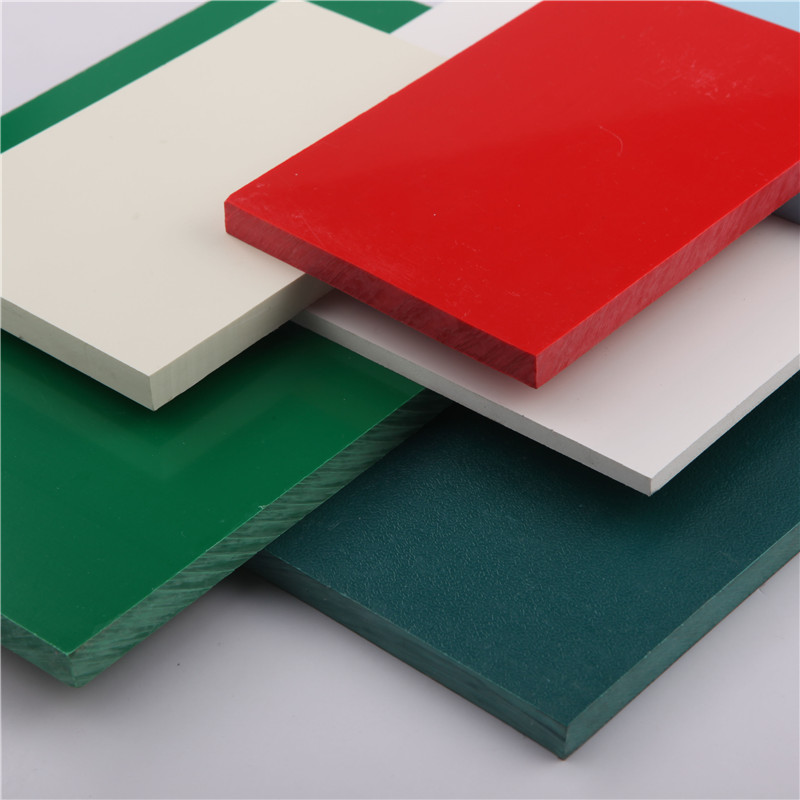

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025