12월 . 12, 2024 11:55 Back to list

gas pipe fittings

Understanding Gas Pipe Fittings A Comprehensive Overview

Gas pipe fittings are essential components in the construction and maintenance of gas supply systems. They play a critical role in ensuring the safety, efficiency, and reliability of gas transport from the source to end-users, whether it be residential, commercial, or industrial settings. Understanding the different types of gas pipe fittings, their applications, and safety considerations is vital for anyone involved in plumbing, construction, or gas system management.

Types of Gas Pipe Fittings

Gas pipe fittings come in a variety of shapes and sizes, each designed for specific purposes. The most common types include

1. Elbows These fittings are used to change the direction of the gas line. Elbows typically come in 90-degree and 45-degree angles, allowing for flexible routing of gas pipes in confined spaces.

2. Tees Tee fittings allow for the branching of gas lines. They facilitate the connection of two pipes at a 90-degree angle, effectively allowing gases to flow in multiple directions.

3. Couplings and Unions These fittings are used to connect two pieces of pipe. Couplings are permanent connections, while unions can be easily disconnected for maintenance or replacement.

4. Caps and Plugs Caps are used to seal the end of a pipe, preventing gas from leaking. Plugs serve a similar function but are inserted into the pipeline rather than fitting over the pipe end.

5. Adapters These fittings allow for the connection of pipes with different diameters or thread types, ensuring compatibility within a gas supply system.

Materials Used

The construction material for gas pipe fittings is crucial for safety and durability. Common materials include

gas pipe fittings

- Steel Often used for high-pressure gas applications, steel fittings provide strength and robustness. However, they may require additional coating to protect against corrosion.

- Copper Widely used for residential gas lines due to its excellent malleability and resistance to corrosion. Copper fittings are easy to work with and can handle standard gas pressures effectively.

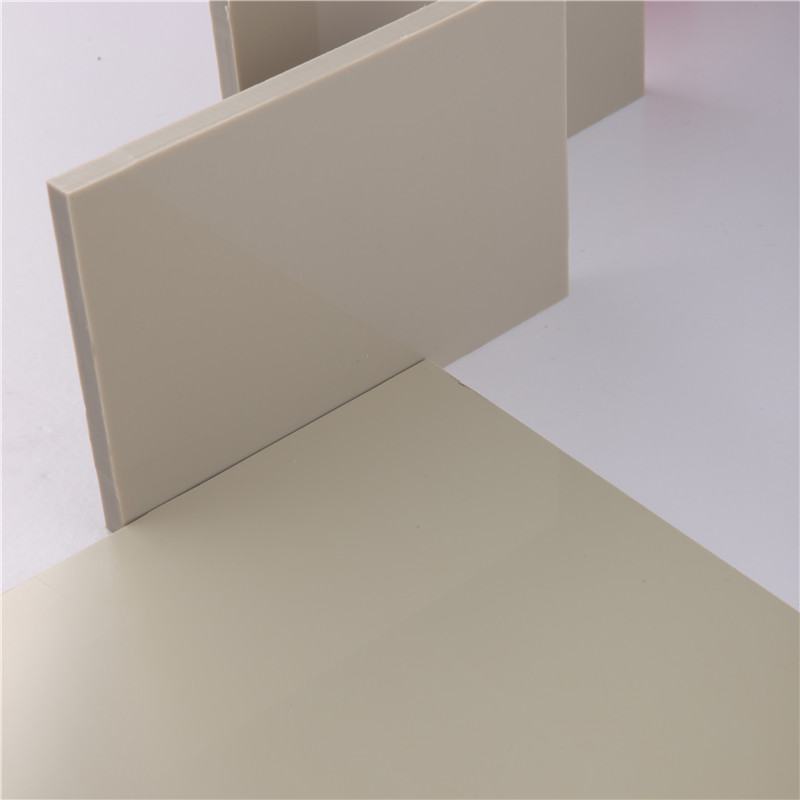

- Plastic Certain types of plastic, such as CPVC and PVC, are suitable for low-pressure gas applications. They are lightweight, resistant to rust, and often more cost-effective. However, their use is usually restricted to specific conditions and gas types.

Safety Considerations

The safe installation and maintenance of gas pipe fittings are paramount. Improper installation can lead to leaks, which pose serious health and safety risks. Here are a few safety tips

- Quality Standards Always use fittings that meet industry standards and certifications. Look for ANSI, ASTM, or CSA markings to ensure compliance with safety regulations.

- Regular Inspections Conduct routine inspections of gas piping systems to check for leaks or wear. Employ the use of soap solutions or specialized leak detection fluids.

- Professional Installation Engage qualified professionals for installation and repairs. Gas systems require specific technical knowledge and expertise to ensure safety and compliance.

- Ventilation Ensure adequate ventilation in areas where gas fittings are used, as this can prevent gas accumulation and potential hazards.

Conclusion

Gas pipe fittings are integral to the safe and efficient delivery of gas. Understanding the different types and their applications, along with adherence to safety practices, can significantly reduce risks associated with gas installations. Whether you are a homeowner, contractor, or facility manager, having a good grasp of gas pipe fittings will enhance the safety and reliability of gas systems. Always prioritize quality materials and professional help to maintain the integrity of your gas supply network.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025