11월 . 19, 2024 22:42 Back to list

era ppr pipes and fittings

Understanding ERA PPR Pipes and Fittings A Comprehensive Guide

In modern plumbing and construction applications, the choice of materials is critical in ensuring durability, efficiency, and long-term performance. Among the various options available in the market, ERA PPR pipes and fittings stand out as a superior choice for numerous reasons. This article aims to provide a comprehensive overview of ERA PPR pipes and fittings, highlighting their features, advantages, applications, and installation practices.

What are PPR Pipes and Fittings?

PPR, or Polypropylene Random Copolymer, is a plastic material that is widely used in the manufacturing of piping systems. ERA PPR pipes and fittings are engineered to meet high standards of quality and performance, making them suitable for both residential and industrial applications. The random copolymer structure of PPR offers better thermal stability and flexibility compared to other types of plastic pipes.

Advantages of ERA PPR Pipes and Fittings

1. Durability One of the most significant advantages of ERA PPR pipes is their exceptional durability. They are resistant to corrosion, scaling, and chemical damage, which extends the lifespan of the pipe system. Unlike metal pipes that can rust or corrode over time, PPR pipes maintain their integrity even in harsh conditions.

2. Heat Resistance ERA PPR pipes can withstand high temperatures, making them suitable for hot water applications. They can handle temperatures up to 95°C, which is essential for various plumbing systems in homes and industries.

3. Lightweight and Easy to Handle PPR pipes are considerably lighter than traditional metal pipes, making them easier to transport and install. This lightweight nature reduces labor costs and simplifies installation processes.

4. Cost-Effectiveness Although the initial cost of purchasing PPR pipes may be slightly higher than some alternatives, their durability and low maintenance mean lower long-term expenses. Additionally, the ease of installation saves both time and money.

era ppr pipes and fittings

5. Environmental Friendly ERA PPR pipes are recyclable and do not leach harmful chemicals into the environment, making them an eco-friendly option for plumbing systems.

Applications of ERA PPR Pipes and Fittings

ERA PPR pipes and fittings are versatile and can be used in a wide range of applications. They are ideal for

- Cold and Hot Water Supply Due to their resistance to heat and pressure, they are often used in residential plumbing systems for both hot and cold water distribution. - Industrial Applications They are suitable for transporting chemicals and liquids in various industries, owing to their resistance to corrosion. - Heating Systems ERA PPR pipes are widely used in underfloor heating systems due to their ability to handle high temperatures.

Installation Practices

The installation of ERA PPR pipes and fittings is straightforward but requires careful attention to detail. Proper techniques should be followed to ensure a leak-free system

1. Cutting Use a pipe cutter to obtain clean cuts, avoiding burrs that could affect fittings. 2. Fusion Welding The most common method for joining PPR pipes and fittings is the socket fusion technique, which involves heating both ends of the pipe and fitting before joining them. 3. Support and Fixing Adequate supports should be provided to prevent sagging and ensure stability, while allowing for thermal expansion.

Conclusion

ERA PPR pipes and fittings represent a modern solution for plumbing and industrial needs, combining durability, efficiency, and environmental benefits. Their widespread applications and ease of installation make them a preferred choice for professionals across various sectors. Investing in ERA PPR systems not only enhances the integrity of plumbing systems but also contributes to sustainable development objectives by minimizing environmental impact. As the demand for reliable and efficient plumbing solutions continues to grow, ERA PPR pipes stand ready to deliver superior performance for years to come.

-

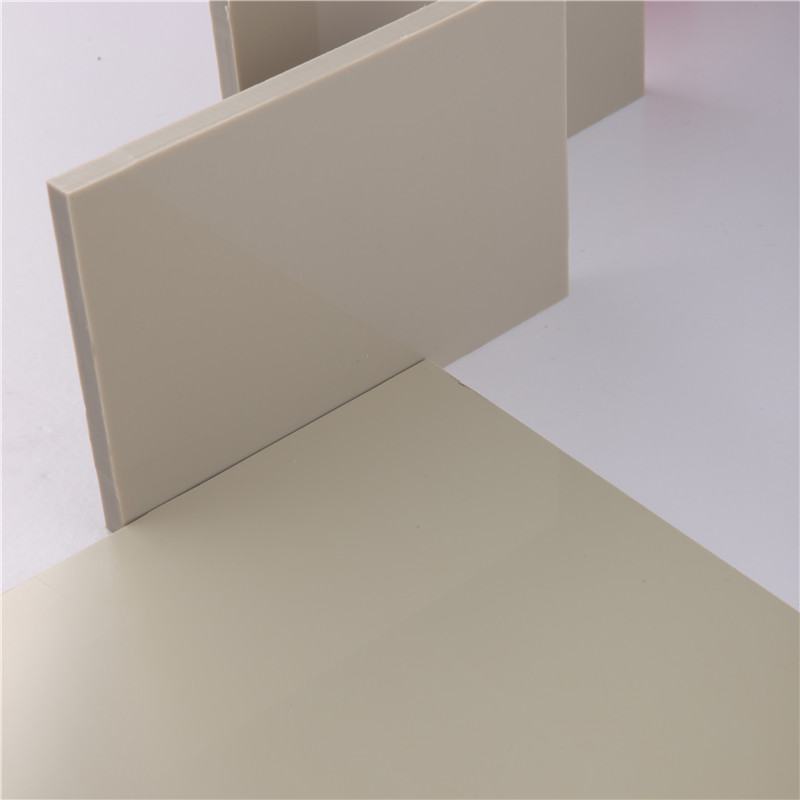

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025