ಜನ . 19, 2025 23:55 Back to list

hdpe plastic welding rods

High-Density Polyethylene (HDPE) plastic welding rods are indispensable in the realm of plastic fabrication and repair. As industries continue to innovate, there's a growing demand for materials that provide both durability and flexibility. This article delves into the essential characteristics, applications, and benefits of HDPE plastic welding rods, offering insights derived from real-world experience and professional expertise.

Trust in HDPE plastic welding rods is bolstered by documented success stories and field assessments. Their capacity to provide long-lasting and watertight seals has been validated time and again, making them a preferred choice for projects demanding high-integrity welds. Moreover, the relatively low thermal conductivity of HDPE ensures that joints can withstand significant thermal cycling without degrading, an attribute that enhances their suitability for use in diverse climates and conditions. As the landscape of infrastructure and materials technology evolves, the reliance on HDPE plastic welding rods is anticipated to grow. Their adaptability and proven performance in crafting durable constructions not only reinforce trust but also set a benchmark for future innovations in plastic welding and fabrication methodologies. Professionals seeking to leverage HDPE rods should remain abreast of the latest advancements and industry practices. Continuous learning and skill enhancement are critical for maintaining the high standards required in complex projects. Acquiring expertise in advanced welding techniques and equipment ensures that practitioners can meet the multifaceted demands of modern construction and repair tasks efficiently. In summation, HDPE plastic welding rods stand as a testament to material innovation, blending resilience with versatility. Their role in ensuring the durability and reliability of structures across various sectors is unequivocal, driven by experienced professionals who champion their use. Through continued exploration and application, HDPE rods will undoubtedly remain at the forefront of plastic welding solutions, setting the foundation for sustained industrial growth and infrastructure development.

Trust in HDPE plastic welding rods is bolstered by documented success stories and field assessments. Their capacity to provide long-lasting and watertight seals has been validated time and again, making them a preferred choice for projects demanding high-integrity welds. Moreover, the relatively low thermal conductivity of HDPE ensures that joints can withstand significant thermal cycling without degrading, an attribute that enhances their suitability for use in diverse climates and conditions. As the landscape of infrastructure and materials technology evolves, the reliance on HDPE plastic welding rods is anticipated to grow. Their adaptability and proven performance in crafting durable constructions not only reinforce trust but also set a benchmark for future innovations in plastic welding and fabrication methodologies. Professionals seeking to leverage HDPE rods should remain abreast of the latest advancements and industry practices. Continuous learning and skill enhancement are critical for maintaining the high standards required in complex projects. Acquiring expertise in advanced welding techniques and equipment ensures that practitioners can meet the multifaceted demands of modern construction and repair tasks efficiently. In summation, HDPE plastic welding rods stand as a testament to material innovation, blending resilience with versatility. Their role in ensuring the durability and reliability of structures across various sectors is unequivocal, driven by experienced professionals who champion their use. Through continued exploration and application, HDPE rods will undoubtedly remain at the forefront of plastic welding solutions, setting the foundation for sustained industrial growth and infrastructure development.

Share:

Next:

Latest news

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

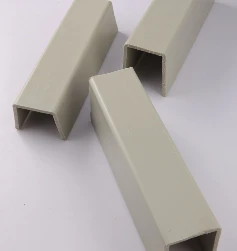

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025