កុម្ភៈ . 12, 2025 17:59 Back to list

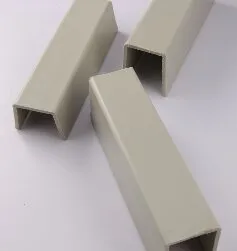

pp sheet

Polypropylene (PP) sheets have emerged as one of the most versatile and popular materials in the manufacturing industry, revolutionizing the way products are designed and produced. With decades of proven performance, PP sheets have become an essential component across a multitude of sectors, providing unmatched benefits that cater to both industrial and commercial applications.

The authoritativeness of PP sheets is evident in their widespread acceptance and integration into global supply chains. Leading manufacturers continue to invest in research and development to enhance the properties and applications of PP sheets, solidifying their standing as a material of choice. Innovations in polymer technology have led to the development of advanced PP sheet variants with improved impact resistance and clarity, expanding their use in areas such as food packaging and consumer electronics where visual appeal and strength are critical. From experiential insights, businesses have observed significant cost savings associated with the use of PP sheets, given their low density and ease of fabrication. Their lightweight nature reduces transportation costs and handling time, streamlining logistics and operational efficiency. Furthermore, their ability to be fabricated on-site reduces lead times and dependency on external suppliers, offering companies greater control over their production processes and timelines. PP sheets also demonstrate impressive thermal resistance properties, maintaining their form and functionality in varying temperatures. This makes them suitable for both indoor and outdoor applications, where thermal stability is a key concern. Industries that operate under fluctuating temperatures, such as agriculture and construction, find PP sheets particularly beneficial for creating durable enclosures and load-bearing structures that endure the elements. In conclusion, the multifaceted advantages of PP sheets—ranging from their durability and customization potential to their environmental benefits and cost-effectiveness—underscore their role as a cornerstone in modern manufacturing. Their enduring popularity and trust amongst industries globally affirm their position as a material defined by expertise and authoritative performance standards. As technological advancements continue to evolve, PP sheets are expected to expand their influence, paving the way for innovative applications and sustainable industry solutions.

The authoritativeness of PP sheets is evident in their widespread acceptance and integration into global supply chains. Leading manufacturers continue to invest in research and development to enhance the properties and applications of PP sheets, solidifying their standing as a material of choice. Innovations in polymer technology have led to the development of advanced PP sheet variants with improved impact resistance and clarity, expanding their use in areas such as food packaging and consumer electronics where visual appeal and strength are critical. From experiential insights, businesses have observed significant cost savings associated with the use of PP sheets, given their low density and ease of fabrication. Their lightweight nature reduces transportation costs and handling time, streamlining logistics and operational efficiency. Furthermore, their ability to be fabricated on-site reduces lead times and dependency on external suppliers, offering companies greater control over their production processes and timelines. PP sheets also demonstrate impressive thermal resistance properties, maintaining their form and functionality in varying temperatures. This makes them suitable for both indoor and outdoor applications, where thermal stability is a key concern. Industries that operate under fluctuating temperatures, such as agriculture and construction, find PP sheets particularly beneficial for creating durable enclosures and load-bearing structures that endure the elements. In conclusion, the multifaceted advantages of PP sheets—ranging from their durability and customization potential to their environmental benefits and cost-effectiveness—underscore their role as a cornerstone in modern manufacturing. Their enduring popularity and trust amongst industries globally affirm their position as a material defined by expertise and authoritative performance standards. As technological advancements continue to evolve, PP sheets are expected to expand their influence, paving the way for innovative applications and sustainable industry solutions.

Share:

Next:

Latest news

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025