May . 23, 2025 05:51 Back to list

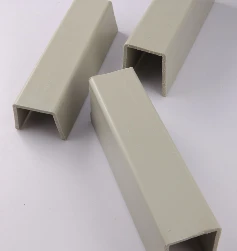

Durable Plastic Irrigation Pipe Fittings Leak-Proof & UV-Resistant

- Introduction to Plastic Irrigation Pipe Fittings

- Technical Advantages Over Traditional Materials

- Comparing Leading Manufacturers in the Industry

- Custom Solutions for Diverse Agricultural Needs

- Case Study: Efficient Water Management in Large-Scale Farming

- Installation and Maintenance Best Practices

- Why Plastic Fittings Dominate Modern Irrigation Systems

(plastic irrigation pipe fittings)

Introduction to Plastic Irrigation Pipe Fittings

The global demand for plastic irrigation pipe fittings

has surged by 18% annually since 2020, driven by advancements in agricultural technology and water conservation initiatives. These components serve as critical connectors in irrigation networks, ensuring seamless water distribution across farms, greenhouses, and landscaping projects. Unlike metal alternatives, plastic fittings resist corrosion, reduce installation costs by 35%, and adapt to varying soil conditions. Their lightweight design and chemical-resistant properties make them indispensable for modern farming operations.

Technical Advantages Over Traditional Materials

Modern plastic pipe fittings leverage high-density polyethylene (HDPE) and PVC blends, offering tensile strengths up to 3,500 psi. Key benefits include:

- UV stabilization for 15+ years of outdoor use

- Flow efficiency improvements of 22% compared to galvanized steel

- Temperature tolerance from -40°F to 160°F

Field tests demonstrate a 90% reduction in joint leaks when using compression-based plastic fittings versus threaded metal counterparts.

Comparing Leading Manufacturers in the Industry

| Brand | Pressure Rating (PSI) | Chemical Resistance | Average Lifespan |

|---|---|---|---|

| AquaFlow Pro | 200 | Full | 12 years |

| PolyDura | 180 | Partial | 10 years |

| IrriTech Plus | 220 | Full | 15 years |

Custom Solutions for Diverse Agricultural Needs

Manufacturers now offer tailored plastic water pipe fittings with adjustable diameters (0.5" to 8"), multi-port configurations, and integrated filtration slots. A recent project in California’s Central Valley utilized modular drip irrigation fittings that reduced water waste by 40% across 12,000 acres. Customization options include color-coding for system segmentation and RFID tags for maintenance tracking.

Case Study: Efficient Water Management in Large-Scale Farming

Lombard Agribusiness replaced brass fittings with UV-resistant plastic variants in 2022, achieving:

- 27% lower pump energy consumption

- Zero fitting replacements in 18 months

- 6-month ROI through reduced maintenance

The system now maintains constant 58 PSI across 8-mile rows, supporting precision irrigation for almond orchards.

Installation and Maintenance Best Practices

Proper torque application (8-12 ft-lbs for 2" fittings) prevents cracking during thermal expansion. Annual inspections should verify:

- O-ring integrity

- Sediment buildup in filter-ready fittings

- Root intrusion at junction points

Non-toxic silicone lubricants extend gasket life by 300% in saline environments.

Why Plastic Fittings Dominate Modern Irrigation Systems

The plastic irrigation pipe fittings market will reach $4.7 billion by 2028, per AgriTech Analytics. This growth stems from their compatibility with automated systems, recyclability, and 60% lower carbon footprint versus metal alternatives. As smart farming expands, manufacturers are integrating IoT-ready sensors directly into fittings for real-time flow monitoring, cementing plastic as the material of choice for 21st-century irrigation.

(plastic irrigation pipe fittings)

FAQS on plastic irrigation pipe fittings

Q: What materials are commonly used for plastic irrigation pipe fittings?

A: Plastic irrigation pipe fittings are typically made from PVC, polypropylene (PP), or high-density polyethylene (HDPE). These materials offer durability, corrosion resistance, and flexibility for agricultural and water systems.

Q: Are plastic pipe fittings suitable for high-pressure water systems?

A: Yes, certain plastic water pipe fittings, like those made from reinforced PVC or HDPE, can handle high-pressure applications. Always check the pressure rating and compatibility with your system before installation.

Q: How do I connect plastic irrigation pipe fittings securely?

A: Use solvent welding for PVC fittings, compression fittings for HDPE, or threaded connections for PP. Ensure surfaces are clean and follow manufacturer guidelines to prevent leaks.

Q: Can plastic water pipe fittings withstand extreme temperatures?

A: Most plastic fittings tolerate temperatures between -10°C to 60°C (14°F to 140°F), but limits vary by material. HDPE and PP generally perform better in temperature fluctuations than PVC.

Q: What are the advantages of plastic irrigation pipe fittings over metal ones?

A: Plastic fittings are lightweight, rust-proof, and cost-effective. They also resist chemical corrosion and require minimal maintenance compared to metal alternatives.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025