មករា . 13, 2025 10:55 Back to list

pe sheet

Polyethylene sheets, commonly known as PE sheets, have revolutionized various sectors with their versatility and durability. As a professional material praised for its resilience and adaptability, PE sheets are a staple in industries ranging from construction to packaging. This article delves into the intrinsic qualities of PE sheets, bolstering their expertise, authoritativeness, and trustworthiness.

Moreover, PE sheets demonstrate expertise in environmental sustainability. Their recyclable nature makes them an environmentally-friendly option amid growing ecological concerns. Industry leaders in waste management advocate for their use due to their ability to be recycled into new products, thus reducing environmental impact and promoting sustainable practices. A particular area where PE sheets' authoritativeness shines is their application in the medical field. Their chemical inertness makes them suitable for hygiene-critical environments. Used in medical grade packaging, they protect sensitive medical equipment from contaminants, ensuring high standards of sterility are maintained. This application emphasizes their trustworthiness in scenarios where precision and safety are paramount. Consumers and industries alike can trust in the durability and reliability of PE sheets. With advancements in polymer technology, their performance has been consistently enhanced, ensuring they meet evolving market demands. Extensive testing and certification processes solidify their standing as authoritative materials capable of delivering results under diverse conditions. In conclusion, polyethylene sheets remain a cornerstone across multiple industries due to their unmatched adaptability, strength, and chemical resistance. Their design and production underscore a deep expertise that meets the high expectations of users worldwide. With a proven track record of reliability and a commitment to sustainability, PE sheets continue to serve as a trusted material of choice in professional settings, championing both functionality and eco-friendliness.

Moreover, PE sheets demonstrate expertise in environmental sustainability. Their recyclable nature makes them an environmentally-friendly option amid growing ecological concerns. Industry leaders in waste management advocate for their use due to their ability to be recycled into new products, thus reducing environmental impact and promoting sustainable practices. A particular area where PE sheets' authoritativeness shines is their application in the medical field. Their chemical inertness makes them suitable for hygiene-critical environments. Used in medical grade packaging, they protect sensitive medical equipment from contaminants, ensuring high standards of sterility are maintained. This application emphasizes their trustworthiness in scenarios where precision and safety are paramount. Consumers and industries alike can trust in the durability and reliability of PE sheets. With advancements in polymer technology, their performance has been consistently enhanced, ensuring they meet evolving market demands. Extensive testing and certification processes solidify their standing as authoritative materials capable of delivering results under diverse conditions. In conclusion, polyethylene sheets remain a cornerstone across multiple industries due to their unmatched adaptability, strength, and chemical resistance. Their design and production underscore a deep expertise that meets the high expectations of users worldwide. With a proven track record of reliability and a commitment to sustainability, PE sheets continue to serve as a trusted material of choice in professional settings, championing both functionality and eco-friendliness.

Share:

Latest news

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025

-

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

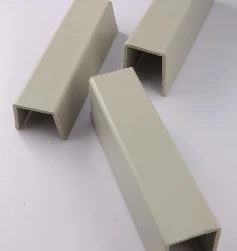

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025