ធ្នូ . 12, 2024 11:26 Back to list

hdpe welding rod 4mm

Understanding HDPE Welding Rods The 4mm Advantage

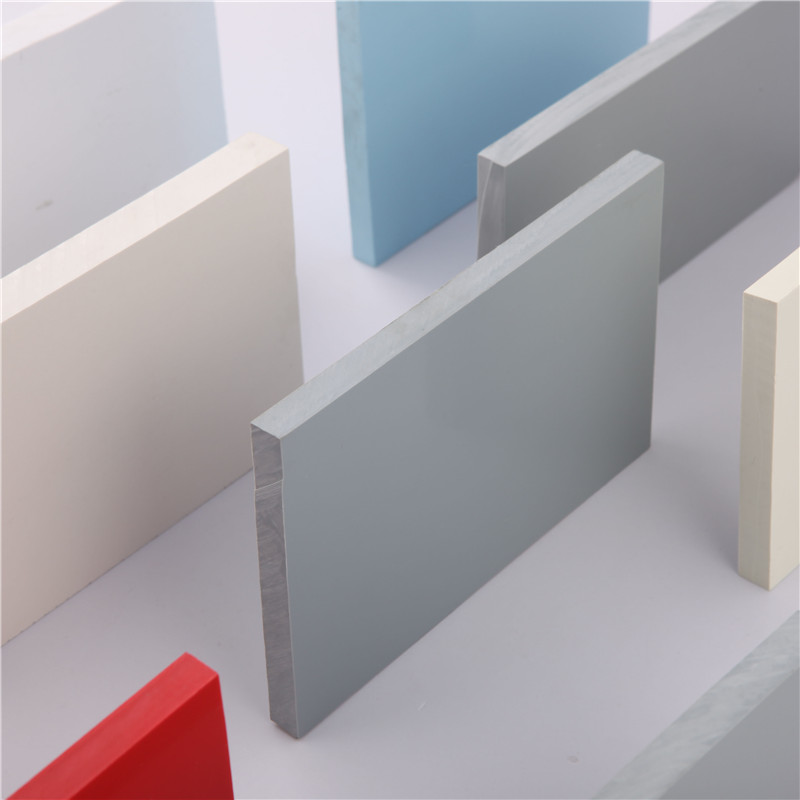

High-density polyethylene (HDPE) is a versatile thermoplastic widely used in a variety of applications due to its strength, durability, and resistance to chemicals and moisture. One of the key components in working with HDPE is the welding rod, which is essential for the fabrication and repair of HDPE products. In this article, we will focus on the 4mm HDPE welding rod, exploring its benefits, applications, and the techniques involved in using it effectively.

What is HDPE Welding Rod?

HDPE welding rods are made from the same material as HDPE sheets and components, ensuring compatibility during the welding process. The 4mm diameter is a popular choice among fabricators and repair technicians because it strikes a perfect balance between strength and usability. This size is particularly suited for various applications where precision and flexibility are required.

Benefits of Using 4mm HDPE Welding Rods

1. Ease of Use The 4mm size offers excellent maneuverability. It is thin enough to allow for detailed work while providing sufficient material for structural integrity. This makes it ideal for both professionals and DIY enthusiasts.

2. Strong Welds When welded correctly, HDPE rods create robust and resilient joints. The chemical structure of HDPE means that welds can often be as strong as the base material itself, ensuring longevity and durability in the final product.

3. Versatility 4mm HDPE welding rods can be used in a multitude of applications, including tanks, pipes, liners, and other assemblies. Their adaptability makes them an essential tool in various industries, from manufacturing to construction and beyond.

4. Corrosion Resistance The inherent properties of HDPE provide excellent resistance to chemicals, making 4mm welding rods suitable for projects where exposure to harsh substances is a concern. This makes them ideal for use in environments like sewage treatment plants, chemical processing facilities, and marine applications.

5. Cost-Effective Given their strength and durability, 4mm HDPE welding rods can lead to significant cost savings. By creating strong, reliable joints, they reduce the need for replacements and repairs, leading to lower overall maintenance costs.

Applications of 4mm HDPE Welding Rods

The applications for 4mm HDPE welding rods are extensive

hdpe welding rod 4mm

- Industrial Repairs They are commonly used for repairing HDPE tanks, containers, and pipes that may have developed leaks or damage over time. The speed and effectiveness of the weld can restore functionality quickly.

- Custom Fabrication In manufacturing, the rods can be utilized to create custom HDPE components, ensuring that the pieces fit together perfectly and meet specific requirements.

- Aquaculture Their resistance to corrosion and environmental degradation makes them a favorite in aquaculture, where they are used for constructing tanks, cages, and other systems that hold or maintain water.

- Agricultural Uses In agriculture, 4mm HDPE welding rods can be employed to build irrigation systems and storage tanks that stand up to the challenges of weather and chemicals used in farming.

Welding Techniques

Welding with HDPE rods requires skill and knowledge of suitable techniques. Common methods include

- Hot Air Welding This technique uses a hot air tool to melt both the HDPE rod and the parent material, allowing them to fuse. It's ideal for creating long seams effectively.

- Extrusion Welding In this method, the HDPE rod is melted and extruded through a nozzle onto the workpiece, which is particularly effective for thicker materials or large areas.

- Butt Welding For joining two flat pieces of HDPE, butt welding allows the ends of the materials to be melted together, creating a strong bond when cooled.

Conclusion

In conclusion, the 4mm HDPE welding rod stands out as a versatile and practical tool in the world of welding and fabrication. Its numerous advantages, including ease of use, strength, versatility, and cost-effectiveness, make it a preferred choice for many applications. Whether used for industrial repairs, custom fabrication, or agricultural needs, these welding rods play a crucial role in creating durable and reliable HDPE assemblies. As you embark on your next project, consider the benefits of integrating 4mm HDPE welding rods into your workflow, ensuring the quality and longevity of your work.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025