ធ្នូ . 10, 2024 03:56 Back to list

High-Density Polyethylene Reinforced Spiral Corrugated Drainage Pipes for Enhanced Durability and Performance

Innovative Applications of HDPE Reinforced Spiral Corrugated Pipes

In recent years, high-density polyethylene (HDPE) reinforced spiral corrugated pipes have gained significant attention in various industries due to their superior performance characteristics and versatility. These pipes are designed to withstand harsh environmental conditions while providing an efficient solution for drainage, sewage systems, and other fluid transportation needs. This article will explore the features, advantages, and applications of HDPE reinforced spiral corrugated pipes.

Understanding HDPE Reinforced Spiral Corrugated Pipes

HDPE is a thermoplastic polymer known for its high strength-to-density ratio, making it a popular choice for a range of applications. The reinforced spiral structure of these pipes enhances their load-bearing capacity and durability. The corrugation not only adds strength but also prevents deformation under pressure, ensuring longevity and reliability.

The manufacturing process involves extrusion technology that produces pipes with a spiral design which allows for a flexible yet solid structure. This design reduces the weight of the pipes compared to traditional concrete or metal pipes while maintaining their structural integrity. Additionally, the seamless nature of HDPE eliminates the risk of leaks, enhancing the overall efficiency of the piping systems.

Advantages of HDPE Reinforced Spiral Corrugated Pipes

1. Durability and Longevity One of the most significant benefits of HDPE pipes is their resistance to corrosion, chemicals, and extreme temperatures. Unlike metal pipes that may rust and degrade over time, HDPE maintains its integrity, resulting in a longer lifespan.

3. Flexibility The flexibility of HDPE allows the pipes to be easily bent or curved, which can be beneficial in various installation scenarios, especially in tight or complex spaces where traditional rigid pipes might be cumbersome.

4. Cost-Effectiveness Due to their durability and low maintenance requirements, HDPE reinforced pipes can be more economical over time. Their resistance to damage and the absence of corrosive breakdown translate to lower total lifecycle costs.

hdpe reinforced spiral corrugated pipe

5. Environmental Impact HDPE is recyclable, making it an environmentally friendly option. The reduced need for maintenance and replacements leads to less waste, benefiting the environment further.

Applications of HDPE Reinforced Spiral Corrugated Pipes

1. Stormwater Management These pipes are widely used in stormwater drainage systems. Their high flow capacity helps manage runoff effectively, preventing flooding and waterlogging, especially in urban areas.

2. Sewer Systems HDPE reinforced pipes are commonly used in sewage and wastewater treatment facilities. Their resistance to chemicals and corrosion makes them an ideal choice for transporting wastewater, ensuring sanitary conditions and compliance with environmental regulations.

3. Agricultural Irrigation Agriculture relies heavily on efficient water management systems. HDPE reinforced spiral corrugated pipes enable effective irrigation solutions, delivering water efficiently to crops while withstanding the dynamic soil conditions.

4. Industrial Applications In various industries, such as mining and construction, HDPE pipes facilitate the transportation of slurry, chemicals, and other materials. Their durability ensures they can withstand the rigors of industrial environments.

5. Telecommunication Ducts The flexibility of HDPE pipes makes them suitable for use as conduits for telecommunications and electrical cabling, safeguarding them from potential damage.

Conclusion

HDPE reinforced spiral corrugated pipes represent a revolutionary development in piping technology, offering exceptional durability, flexibility, and cost-effectiveness across a wide range of applications. Their ability to withstand challenging environmental conditions while maintaining a lightweight structure has positioned them as a preferred solution for modern infrastructure needs. As industries continue to prioritize sustainable and efficient practices, the adoption of HDPE reinforced pipes is likely to grow, paving the way for enhanced performance in fluid transportation and management systems. As innovation continues to drive advancements in materials and construction techniques, HDPE reinforced spiral corrugated pipes will undeniably play a crucial role in shaping the future of infrastructure development.

-

High Quality PVC Round Rod for Industrial & DIY Applications

NewsJul.28,2025

-

High Quality PVC Pipe Fitting - Durable & Leak-Proof Solutions

NewsJul.28,2025

-

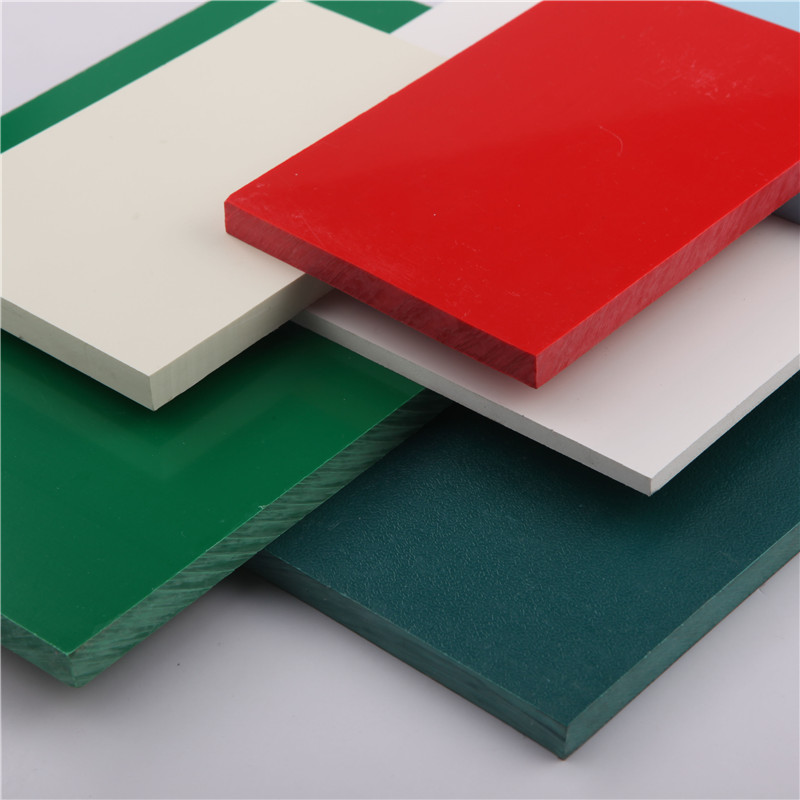

High-Quality PVC Rigid Sheet (Glossy Surface) for Industrial Use

NewsJul.26,2025

-

High Quality PVC Rigid Sheet (Embossed Surface) for Industrial Use

NewsJul.25,2025

-

High Quality PVC Soft Sheet for Flexible Applications | Durable & Customizable

NewsJul.24,2025

-

High-Quality UPVC Water Supply Pipe for Durable Plumbing Solutions

NewsJul.23,2025