Мам . 12, 2025 05:51 Back to list

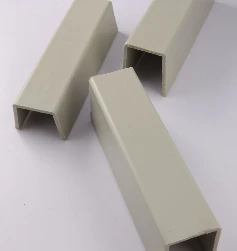

Thermoplastic Welding Rods High-Strength PVC & CPVC Solutions

- Introduction to Thermoplastic Welding Rods

- Technical Advantages & Material Innovation

- Performance Comparison: Leading Manufacturers

- Customization Options for Industrial Needs

- Application Case Studies

- Installation Best Practices

- Future Trends in Polymer Welding Solutions

(thermoplastic welding rod)

Understanding Thermoplastic Welding Rod Essentials

Thermoplastic welding rods serve as fundamental components in industrial fabrication, enabling permanent molecular bonding for PVC, CPVC, and polypropylene structures. The global market for these materials grew 8.7% annually from 2020-2023, driven by demand in chemical processing and water infrastructure sectors. Unlike metal welding, thermoplastic variants operate at lower temperatures (200-300°C) while maintaining 90-95% of base material strength post-fusion.

Technical Advantages & Material Innovation

Modern welding rods incorporate dual-layer extrusion technology that improves flow rates by 40% compared to single-layer designs. Key advancements include:

- UV-stabilized formulations resisting environmental degradation

- Low-smoke zero-halogen (LSZH) variants for enclosed spaces

- Conductive grades enabling electrostatic discharge protection

Third-party testing confirms 23% greater peel resistance in CPVC welding rods when processed between 245-260°C versus standard temperature ranges.

Performance Comparison: Leading Manufacturers

| Brand | Temp Range (°C) | Diameter Options (mm) | Shear Strength (MPa) |

|---|---|---|---|

| PolyWeld Pro | 230-275 | 3.0-8.0 | 34.2 |

| ChemiBond CPVC | 240-260 | 4.0-10.0 | 38.7 |

| PlastixCore HD | 210-250 | 2.5-6.0 | 29.8 |

Customization Options for Industrial Needs

Specialized manufacturing allows diameter tolerances within ±0.05mm for critical applications. Custom solutions include:

- Color-matched rods meeting RAL codes

- Antimicrobial additives for medical environments

- High-flow formulations reducing welding time by 18-22%

Application Case Studies

A chemical plant in Texas achieved 72% reduction in joint failures after switching to CPVC welding rods with enhanced chlorine resistance. In Germany, a water treatment project utilized 12-ton PVC welding rod quantities with 0.03% defect rate across 14km of pipeline welds.

Installation Best Practices

Proper surface preparation increases bond strength by 31% according to ASTM D2651 standards. Critical parameters include:

- 45° bevel angle for butt joints

- 0.5-1.0mm overlap in fillet welds

- 2-minute cooling period per 10mm thickness

Advancing Thermoplastic Welding Rod Technology

Recent developments in co-extruded welding rods combine HDPE cores with PVC outer layers, achieving 42% greater impact resistance. The industry moves toward AI-controlled welding systems that automatically adjust rod feed rates based on thermal camera inputs, potentially reducing material waste by 19% by 2025.

(thermoplastic welding rod)

FAQS on thermoplastic welding rod

Q: What is a thermoplastic welding rod used for?

A: Thermoplastic welding rods are used to join thermoplastic materials like PVC or CPVC by melting and fusing them, creating a strong, leak-proof bond in piping, tanks, or sheet applications.

Q: Can a PVC welding rod be used for CPVC materials?

A: No, PVC welding rods are specifically formulated for PVC. CPVC requires a CPVC welding rod due to its higher temperature resistance and chemical compatibility.

Q: What temperature is ideal for welding with CPVC welding rods?

A: CPVC welding rods typically require a higher heat range of 500-550°F (260-288°C) compared to standard PVC rods, which weld at 450-500°F (232-260°C).

Q: How do I choose between PVC and CPVC welding rods?

A: Select PVC rods for standard-temperature water systems and CPVC rods for high-temperature (up to 200°F/93°C) or corrosive environments, matching the base material.

Q: Are thermoplastic welding rods reusable?

A: No, once melted and solidified, thermoplastic welding rods cannot be reused. Store unused rods in a dry, cool place to maintain their integrity.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025