Ноя . 06, 2024 17:32 Back to list

pp sandwich sheet

Understanding PP Sandwich Sheet A Versatile Material for Modern Applications

In today’s rapidly evolving industrial landscape, the demand for innovative materials that combine strength, lightweight properties, and versatility is on the rise. One such material that has gained significant attention is the PP (Polypropylene) sandwich sheet. This advanced composite is recognized for its exceptional performance in various applications, ranging from construction to automotive manufacturing.

What is a PP Sandwich Sheet?

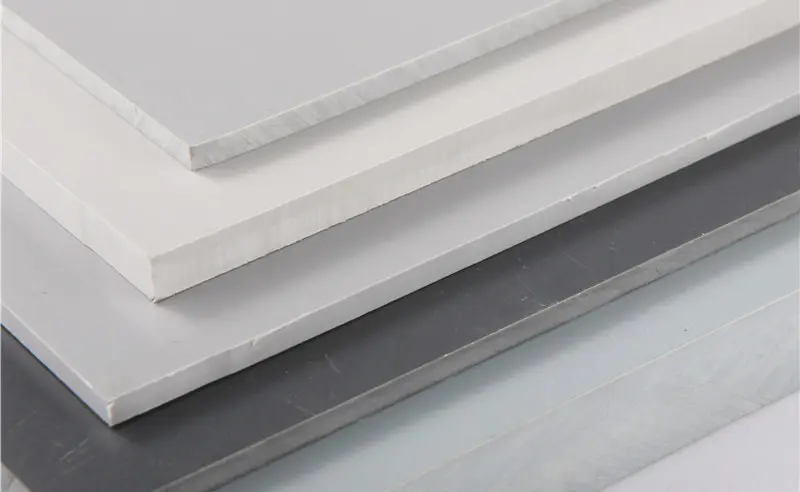

A PP sandwich sheet is a composite panel consisting of a core layer made from polypropylene, sandwiched between two outer layers of polypropylene or other suitable materials. This structure not only enhances the mechanical properties of the sheet but also significantly reduces its weight, making it an ideal choice for applications requiring durability without the added bulk. The lightweight nature of PP sandwich sheets contributes to energy savings during transportation and installation, making them a favored option in many industries.

Key Benefits of PP Sandwich Sheets

One of the most compelling advantages of PP sandwich sheets is their high strength-to-weight ratio. Despite being lightweight, these sheets exhibit impressive rigidity and impact resistance. This makes them suitable for use in various demanding environments, including the construction of walls, ceilings, and partitions.

Additionally, PP sandwich sheets are resistant to moisture, chemicals, and UV radiation. This characteristic ensures that they maintain their structural integrity and aesthetic appeal over time, even when exposed to harsh conditions. Furthermore, the non-toxic nature of polypropylene makes these sheets safe for use in environments such as food packaging and medical applications.

pp sandwich sheet

Applications of PP Sandwich Sheets

The versatility of PP sandwich sheets opens the door to numerous applications across different sectors. In the construction industry, they are commonly used for wall cladding, roofing, and signage due to their lightweight yet sturdy properties. They provide excellent insulation, thus contributing to energy efficiency in buildings.

In the automotive sector, PP sandwich sheets find their application in the manufacturing of interior panels and components. Their lightweight characteristics help reduce the overall weight of vehicles, which can lead to improved fuel efficiency.

Moreover, the packaging industry benefits from PP sandwich sheets as they offer a reliable solution for creating durable, lightweight, and protective packaging for a variety of products. Their resistance to moisture and chemicals enhances the shelf life of packaged goods, making them highly sought after in both industrial and consumer markets.

Conclusion

The PP sandwich sheet represents a remarkable evolution in material science, offering a blend of durability, lightweight, and versatility. As industries continue to seek out innovative solutions to meet modern challenges, the adoption of PP sandwich sheets is likely to increase. This material not only meets the demands of construction and automotive sectors but also provides sustainable options for packaging and other applications.

In summary, the advantages of PP sandwich sheets—such as their strength, moisture resistance, and ease of fabrication—make them a valuable resource for manufacturers looking to improve efficiency and reduce weight in their products. The future of PP sandwich sheets looks promising, and as advancements in technology continue, we can expect even more applications for this remarkable material.

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025