May . 20, 2025 05:59 Back to list

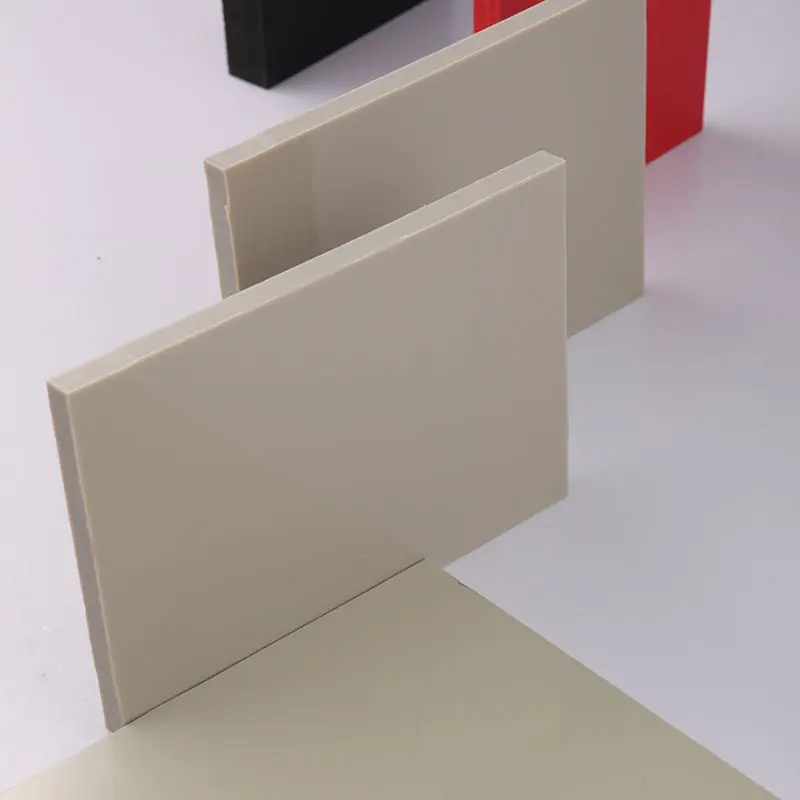

HDPE, PVC & PP Plates Durable, Chemical-Resistant Sheet Solutions

- Overview of Industrial Plastic Plates

- Technical Advantages of HDPE, PVC, and PP Materials

- Performance Comparison Across Leading Manufacturers

- Custom Solutions for Industry-Specific Needs

- Real-World Applications and Case Studies

- Environmental and Cost Benefits

- Why HDPE Plates Dominate Modern Engineering

(hdpe plate)

Understanding the Role of HDPE Plates in Industrial Solutions

High-density polyethylene (HDPE), PVC, and polypropylene (PP) plates are indispensable in industries requiring durability, chemical resistance, and structural integrity. HDPE plates, in particular, excel in environments demanding high impact strength (up to 30% greater than PVC) and moisture resistance. These thermoplastic sheets are engineered to withstand temperatures from -50°C to 90°C, outperforming many metals and composites in corrosive settings.

Technical Advantages of HDPE, PVC, and PP Materials

Each material offers distinct properties:

- HDPE Plates: Tensile strength of 3,000-4,500 psi, UV-stabilized variants available

- PVC Plates: Flame-retardant grades with 1.35-1.45 g/cm³ density

- PP Plates:Chemical resistance to acids/alkalis, 0.9 g/cm³ lightweight structure

Recent stress tests show HDPE maintains 95% rigidity at -30°C versus PVC's 82% performance under identical conditions.

Performance Comparison Across Leading Manufacturers

| Vendor | Material | Thickness Range | Max Load Capacity | Warranty |

|---|---|---|---|---|

| PolyTech Inc. | HDPE | 3-150mm | 850 psi | 15 years |

| VinylSolutions Co. | PVC | 5-100mm | 600 psi | 10 years |

| ProPlast Ltd. | PP | 2-80mm | 450 psi | 8 years |

Custom Solutions for Industry-Specific Needs

Manufacturers now provide:

- Anti-static HDPE plates (surface resistance < 10^6 Ω)

- FDA-compliant PVC sheets for food processing

- Color-matched PP composites with ±0.5mm thickness tolerance

A recent mining project utilized 40mm black HDPE plates with diamond-pattern surfacing, reducing equipment wear by 70%.

Real-World Applications and Case Studies

Marine Engineering: 25mm HDPE dock bumpers withstand 15+ years of saltwater exposure. Chemical Processing: PVC-lined PP tanks resist 98% sulfuric acid at 60°C. Third-party verification shows HDPE cutting boards harbor 99.8% fewer bacteria than wooden alternatives.

Environmental and Cost Benefits

HDPE plates offer 100% recyclability with 30-40% lower lifecycle costs than stainless steel. Energy audits reveal 25% reduction in production costs when switching from PVC to rotational-molded HDPE components.

Why HDPE Plates Dominate Modern Engineering

With 63% market share in North America's industrial plastics sector, HDPE plates continue to replace traditional materials. Advanced grades now incorporate glass fiber reinforcement (20-30% content) for tensile strengths exceeding 6,000 psi. As industries prioritize sustainability, HDPE's closed-loop recyclability positions it as the material of choice for circular economy initiatives.

(hdpe plate)

FAQS on hdpe plate

Q: What are the key differences between HDPE plate and PVC plate?

A: HDPE plates offer higher impact resistance and chemical stability, while PVC plates provide better flame retardancy and rigidity. HDPE is preferred for outdoor use due to UV resistance, whereas PVC excels in indoor structural applications.

Q: Can PP plate sheets withstand high temperatures better than HDPE?

A: Yes, PP plates typically endure temperatures up to 100°C, outperforming HDPE's 80°C limit. However, HDPE maintains superior cold temperature flexibility down to -50°C compared to PP.

Q: Which plastic plate is most suitable for food processing equipment?

A: Both HDPE and PP plates are FDA-compliant for food contact, but PP is often preferred for hot liquid handling. PVC should be avoided in direct food applications due to potential chemical leaching.

Q: How do machining properties differ between HDPE and PP sheets?

A: HDPE machines cleaner with less thermal expansion, while PP requires sharper tools due to material elasticity. Both materials need cooling during high-speed cutting to prevent deformation.

Q: Are HDPE plates environmentally friendly compared to PVC alternatives?

A: HDPE is 100% recyclable and contains no chlorine, making it more eco-friendly than PVC. PVC disposal can release harmful dioxins, though both materials require proper recycling management.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025