12月 . 15, 2024 09:35 Back to list

PVC Welding Rods for Triangle Applications in Construction and Repair Projects

The Essential Guide to Triangle PVC Welding Rods

In the world of plastic fabrication, the selection of materials and tools is paramount to achieving high-quality results. Among the various options available, triangle PVC welding rods have emerged as a popular choice for many professionals and hobbyists alike. This article will provide a comprehensive overview of triangle PVC welding rods, their applications, benefits, and considerations when using them.

Understanding PVC Welding Rods

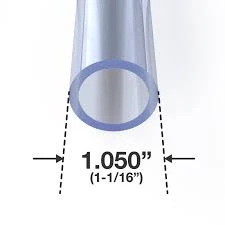

PVC, or polyvinyl chloride, is one of the most widely used plastics in the world, known for its durability, versatility, and cost-effectiveness. Welding rods made from PVC serve as filler materials used in the process of welding or repairing PVC components. Triangle-shaped welding rods, in particular, offer unique advantages when it comes to welding efficiency and quality.

The triangular cross-section of these rods ensures a more substantial surface area when applied to the workpieces, promoting better fusion and bonding. This feature helps to create a stronger and more uniform weld, which is crucial in applications where structural integrity is essential.

Applications of Triangle PVC Welding Rods

Triangle PVC welding rods are utilized in various industries, including construction, automotive, plumbing, and manufacturing. They are perfect for joining or repairing PVC pipes, sheets, and various components used in these sectors. Some specific applications include

1. Plumbing Repairs Triangle PVC rods are commonly used to repair broken or leaking pipes in residential and commercial plumbing systems. The strong welds formed help prevent further leakage and extend the life of the plumbing system.

2. Vehicle Bodywork In the automotive industry, triangle PVC welding rods can be used to repair damaged plastic body panels or components, ensuring that vehicles maintain their aesthetic and functional integrity.

3. Signmaking PVC is frequently used in the production of signs, displays, and promotional materials. Triangle welding rods facilitate the construction and repair of these materials, ensuring a professional finish.

4. Construction In the construction sector, triangle welding rods are used for assembling and repairing PVC-based structures, such as windows, doors, and partitions.

Benefits of Using Triangle PVC Welding Rods

1. Enhanced Weld Strength The triangular shape allows for a more significant contact area, resulting in a stronger weld. This is particularly beneficial in high-stress applications.

triangle pvc welding rod

2. Improved Heat Distribution The design of triangle PVC rods supports better heat distribution during the welding process, minimizing the risk of overheating specific areas and causing warping or degradation of the material.

3. Versatility These rods can be used with various welding techniques, including hot air welding and extrusion welding, making them suitable for a wide range of projects.

4. Cost-Effectiveness PVC welding rods are relatively inexpensive compared to other materials, making them an economically viable choice for both DIY enthusiasts and professionals.

5. Ease of Use For those who are new to welding, triangle PVC rods are user-friendly and can be easily manipulated to create clean and precise welds.

Considerations When Using Triangle PVC Welding Rods

While triangle PVC welding rods offer many advantages, there are several considerations to keep in mind

1. Material Compatibility Always ensure that the welding rod is compatible with the type of PVC you are working with. Different grades of PVC may require specific types of welding rods.

2. Welding Technique Familiarize yourself with the appropriate welding techniques for working with triangle PVC rods. Understanding the correct temperature settings and speed will help achieve the best results.

3. Health Precautions When welding PVC, it's essential to work in a well-ventilated area and wear appropriate personal protective equipment (PPE) to protect against fumes and heat.

4. Surface Preparation Properly prepare the surfaces to be joined by cleaning and, if necessary, roughening the surfaces to enhance the weld quality.

Conclusion

In summary, triangle PVC welding rods are a valuable resource in various applications, offering enhanced strength, versatility, and ease of use. By understanding their properties and applications, fabricators and DIY enthusiasts can harness their potential to achieve high-quality welding results. Whether you're repairing plumbing, working on automotive components, or creating PVC structures, triangle PVC welding rods are a reliable choice for effective and efficient welding.

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025