May . 27, 2025 09:11 Back to list

Translucent PP Sheets Durable, Lightweight & Weather-Resistant Solutions

- Understanding Translucent and Transparent PP Sheets

- Technical Advantages of Polypropylene Sheets

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Real-World Applications Across Industries

- Environmental and Cost Efficiency Metrics

- Why Translucent PP Sheets Dominate Modern Manufacturing

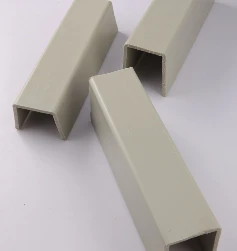

(translucent pp sheet)

Understanding Translucent and Transparent PP Sheets

Translucent and transparent polypropylene (PP) sheets are engineered for applications requiring light diffusion, durability, and chemical resistance. With a global market growth rate of 5.8% CAGR (2023-2030), these materials are increasingly replacing glass and rigid plastics in packaging, automotive, and construction sectors. Unlike standard plastics, translucent PP sheets offer 85-92% light transmittance, while transparent variants achieve up to 95%, making them ideal for displays, medical devices, and UV-resistant outdoor installations.

Technical Advantages of Polypropylene Sheets

Polypropylene sheets excel in tensile strength (30-35 MPa), thermal stability (-20°C to 120°C), and moisture resistance. A 2022 study by Polymer Solutions International revealed that PP sheets reduce component weight by 40% compared to PVC alternatives. Advanced co-polymerization techniques enhance impact resistance, with some grades sustaining 15 kJ/m² Charpy impact strength. Additionally, FDA-compliant grades dominate food packaging, holding a 62% market share in thermoformed containers.

Performance Comparison: Leading Manufacturers

| Manufacturer | Thickness Range (mm) | Light Transmission (%) | Price per kg (USD) | MOQ (tons) |

|---|---|---|---|---|

| Sabic | 0.5-12 | 91 | 2.80 | 5 |

| LyondellBasell | 0.3-15 | 89 | 2.65 | 3 |

| ExxonMobil | 1-10 | 93 | 3.10 | 10 |

| Regional Suppliers | 0.5-8 | 84-88 | 2.20 | 1 |

Custom Solutions for Diverse Industrial Needs

Manufacturers now provide tailored PP sheets with adjustable haze (10-80%), anti-static coatings (surface resistivity 10⁶-10⁸ Ω), and laser-cutting compatibility. For instance, a German automotive supplier reduced assembly costs by 18% using pre-perforated translucent PP sheets with ±0.1mm tolerance. Hybrid grades incorporating 15-20% recycled content meet circular economy mandates without compromising tensile or optical properties.

Real-World Applications Across Industries

Case studies demonstrate versatility:

- Medical: Sterilizable PP trays (0.8mm thickness) withstand 200+ autoclave cycles

- Retail: 92% of premium cosmetic brands use textured translucent PP for anti-counterfeit packaging

- Renewables: 5MW solar panel backsheets utilize UV-stabilized PP with 25-year warranties

Environmental and Cost Efficiency Metrics

Lifecycle analyses show translucent PP sheets generate 68% fewer CO₂ emissions than PET equivalents during production. Bulk purchasing (20+ tons) lowers costs to $1.90/kg, while automated thermoforming achieves 98% material utilization. Post-industrial recycled grades now match virgin material performance at 15-20% cost savings.

Why Translucent PP Sheets Dominate Modern Manufacturing

With 73% of engineers specifying translucent or transparent PP sheets for new projects (2023 Plastics Industry Report), their dominance stems from balanced optical-mechanical performance. Innovations like nano-layered PP films (0.2mm thickness, 94% clarity) and 3D-moldable grades are set to capture 45% of the $9.1 billion clear plastics market by 2026. For OEMs prioritizing sustainability, durability, and design flexibility, polypropylene remains unmatched.

(translucent pp sheet)

FAQS on translucent pp sheet

Q: What is the difference between translucent PP sheet and transparent PP sheet?

A: Translucent PP sheets allow diffused light transmission with some haze, while transparent PP sheets offer clear visibility with minimal light distortion. Both are made of polypropylene but differ in optical clarity. Applications vary based on required visibility levels.

Q: Can polypropylene PP sheets withstand outdoor environments?

A: Yes, polypropylene PP sheets are UV-resistant and moisture-proof, making them suitable for outdoor use. They maintain structural integrity in varying temperatures and resist chemical exposure, ensuring long-term durability.

Q: Are translucent PP sheets food-safe?

A: Translucent PP sheets are FDA-compliant and food-safe when produced without additives. They're widely used in food packaging and processing equipment. Always verify material certifications for specific industry requirements.

Q: What thickness options are available for transparent PP sheets?

A: Transparent PP sheets typically range from 0.5mm to 20mm in thickness. Custom thicknesses can be manufactured for specialized applications. Selection depends on required rigidity and light transmission properties.

Q: How do polypropylene sheets compare to other plastic sheets?

A: PP sheets offer better chemical resistance and lower density than PVC or acrylic alternatives. They provide excellent weldability and flexibility while maintaining cost-effectiveness. Choice depends on specific mechanical and thermal needs.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025