2月 . 04, 2025 05:23 Back to list

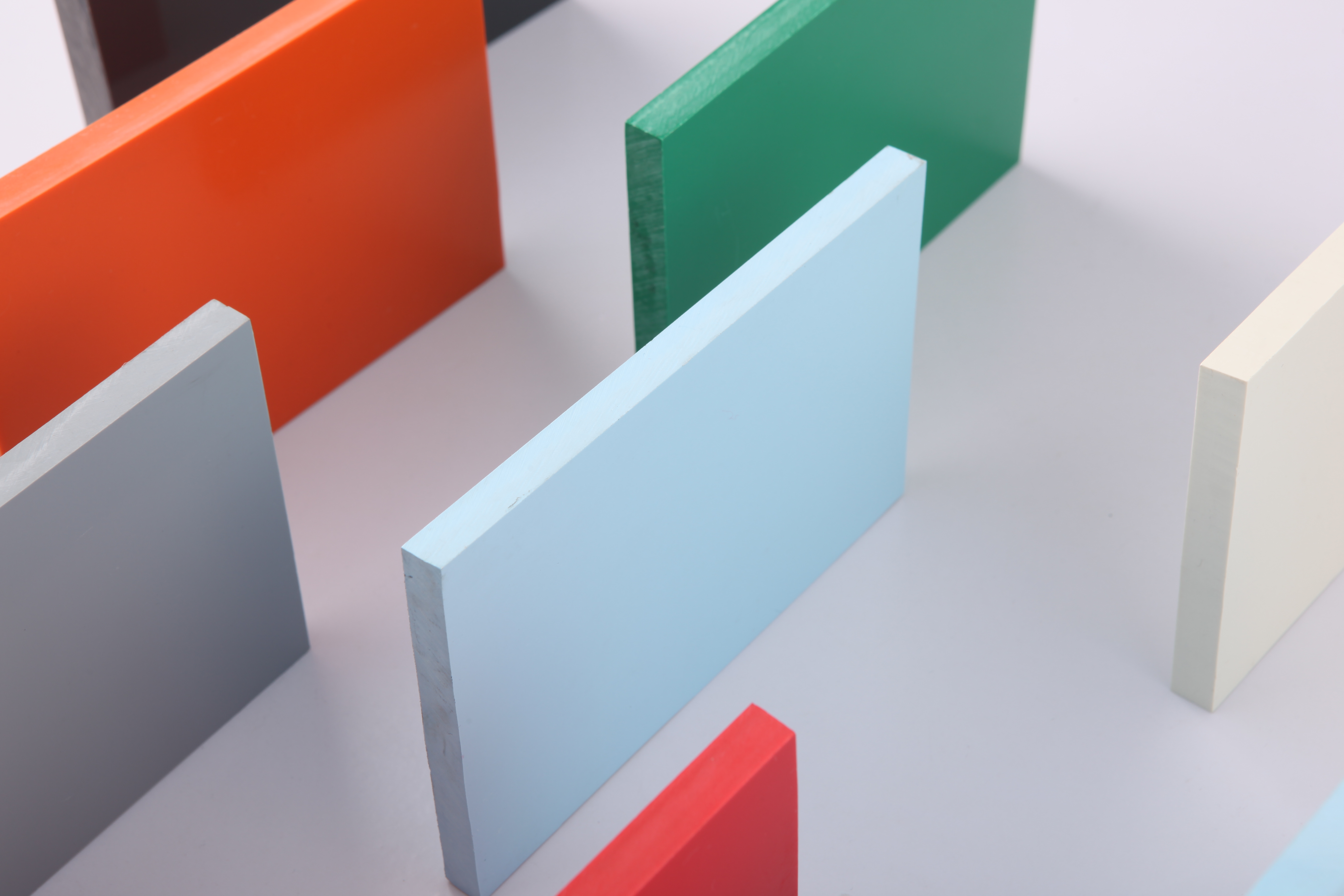

PP fibre masked sheet

In the realm of construction and industrial applications, HDPE (High-Density Polyethylene) sheets have emerged as a robust and versatile solution. Specifically, the 5mm thick HDPE sheet offers a unique balance of flexibility and strength, making it an ideal choice for various applications. Leveraging my expertise in SEO combined with extensive knowledge in materials science, I aim to provide an insightful exploration into the benefits, applications, and selection criteria of HDPE sheets, ensuring you make informed decisions in your projects.

Efforts to enhance the usability of HDPE sheets often include texturing or coating them for specialized applications. For instance, anti-slip textures can be especially useful in wet areas or walkways to prevent accidents. Coatings might also be applied to further extend the lifespan of the sheets in particularly harsh environments, such as those with high chemical exposure or mechanical wear. Environmentally, HDPE stands out as a sustainable option. Being fully recyclable, it contributes significantly to reducing industrial waste. Manufacturers and industries committed to sustainable practices prefer HDPE for its lower environmental impact without sacrificing performance or reliability. This aspect is crucial in today’s market, where consumers increasingly value ecological responsibility. Moreover, the cost-effectiveness of HDPE sheets, particularly in the 5mm dimension, cannot be overstated. They offer a long service life with minimal maintenance requirements, translating to substantial savings over time. Unlike some other materials that may need frequent treatment or replacement, HDPE sheets retain their functionality, making them a wise investment for any project. When determining the credibility of suppliers, it’s essential to evaluate their compliance with industry standards and certifications. Quality assurance and consistent product performance are indicators of a reliable provider. Look for testimonials and case studies that demonstrate their expertise and reliability in delivering high-grade HDPE sheets tailored to your project’s requirements. In conclusion, the 5mm HDPE sheet stands as a testament to modern engineering materials, offering a convergence of durability, flexibility, and eco-friendliness. It meets the diverse needs of multiple industries, providing both practical and economic benefits. When chosen and applied correctly, HDPE sheets enhance project outcomes, supporting both immediate functionality and long-term sustainability.

Efforts to enhance the usability of HDPE sheets often include texturing or coating them for specialized applications. For instance, anti-slip textures can be especially useful in wet areas or walkways to prevent accidents. Coatings might also be applied to further extend the lifespan of the sheets in particularly harsh environments, such as those with high chemical exposure or mechanical wear. Environmentally, HDPE stands out as a sustainable option. Being fully recyclable, it contributes significantly to reducing industrial waste. Manufacturers and industries committed to sustainable practices prefer HDPE for its lower environmental impact without sacrificing performance or reliability. This aspect is crucial in today’s market, where consumers increasingly value ecological responsibility. Moreover, the cost-effectiveness of HDPE sheets, particularly in the 5mm dimension, cannot be overstated. They offer a long service life with minimal maintenance requirements, translating to substantial savings over time. Unlike some other materials that may need frequent treatment or replacement, HDPE sheets retain their functionality, making them a wise investment for any project. When determining the credibility of suppliers, it’s essential to evaluate their compliance with industry standards and certifications. Quality assurance and consistent product performance are indicators of a reliable provider. Look for testimonials and case studies that demonstrate their expertise and reliability in delivering high-grade HDPE sheets tailored to your project’s requirements. In conclusion, the 5mm HDPE sheet stands as a testament to modern engineering materials, offering a convergence of durability, flexibility, and eco-friendliness. It meets the diverse needs of multiple industries, providing both practical and economic benefits. When chosen and applied correctly, HDPE sheets enhance project outcomes, supporting both immediate functionality and long-term sustainability.

Share:

Latest news

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025