nóv . 24, 2024 15:37 Back to list

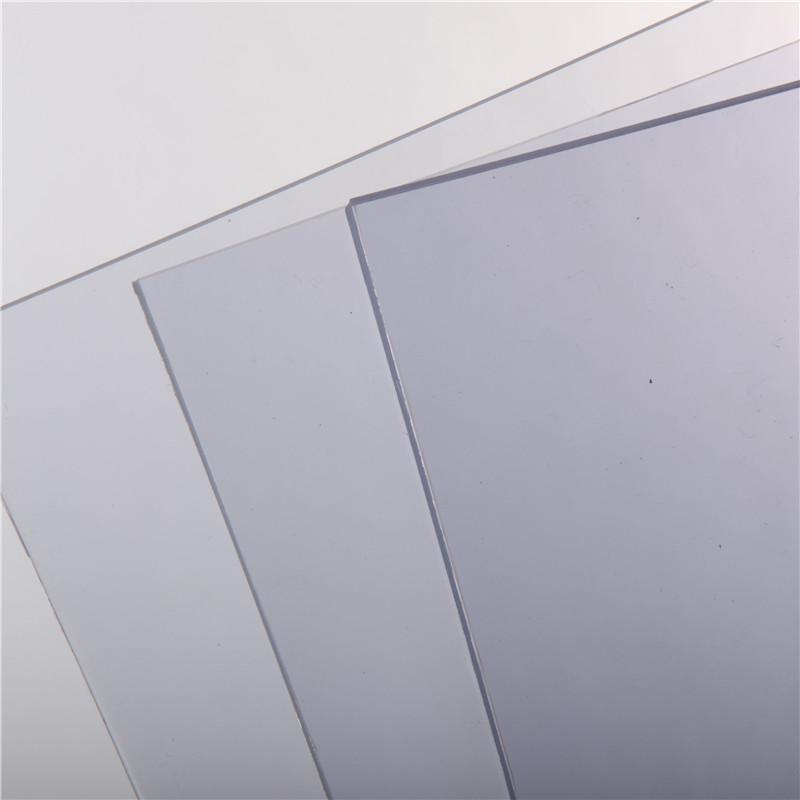

pp rigid sheet

Understanding PP Rigid Sheet A Comprehensive Overview

Polypropylene (PP) rigid sheets are an essential material used in various industries due to their unique properties and versatile applications. This article delves into the characteristics, benefits, applications, and future prospects of PP rigid sheets, providing a thorough understanding of why they have become increasingly popular in recent years.

What is PP Rigid Sheet?

Polypropylene is a thermoplastic polymer that is widely used in packaging, textiles, automotive components, and more. When it comes to rigid sheets, polypropylene is manufactured through a process that enhances its rigidity and strength. These sheets are produced in various thicknesses and sizes, making them suitable for a wide range of applications. The production process typically involves extrusion, where the polypropylene is melted and then formed into sheets that can be cooled and cut to specified dimensions.

Properties of PP Rigid Sheet

PP rigid sheets exhibit several remarkable properties that contribute to their widespread use

1. Lightweight One of the most significant advantages of PP rigid sheets is their low density, which makes them easy to handle, transport, and work with.

2. Chemical Resistance PP is highly resistant to a variety of chemicals, including acids and bases, making it suitable for applications in laboratories and industries where exposure to harsh substances is common.

3. Impact Resistance The toughness of PP rigid sheets enables them to withstand impacts without cracking or breaking, which is essential in packaging and protective applications.

4. Thermal Stability These sheets can resist higher temperatures compared to many other plastics, which allows for their use in environments that may experience heat.

5. Recyclability PP is 100% recyclable, which is a critical feature for environmentally conscious industries. The ability to recycle means that PP rigid sheets can be reused in various capacities, reducing the overall environmental footprint.

Applications of PP Rigid Sheet

pp rigid sheet

Due to their advantageous properties, PP rigid sheets find applications across numerous sectors

1. Packaging In the packaging industry, PP rigid sheets are used to produce boxes, trays, and containers that are lightweight yet durable. Their chemical resistance also makes them ideal for food packaging, ensuring that the contents remain uncontaminated.

2. Signage The graphic arts industry utilizes PP rigid sheets for outdoor and indoor signage. Their ability to withstand weather conditions while maintaining color and clarity makes them a favored choice for displays.

3. Automotive Components In the automotive sector, PP rigid sheets are employed in interior applications such as dashboards and paneling. Their lightweight nature helps in improving fuel efficiency.

4. Medical Applications Due to their sterilization capabilities, PP rigid sheets are widely used in the medical industry for packaging instruments and devices, ensuring safety and hygiene.

5. Construction In construction, these sheets can serve as wall coverings, insulation, and more, providing durability and ease of maintenance.

Future Prospects of PP Rigid Sheets

As environmental concerns continue to rise, the future of PP rigid sheets looks promising. Innovations in recycling technologies are expected to make the process more efficient, supporting the circular economy. Additionally, research into bio-based polypropylene is underway, aiming to produce more sustainable alternatives to traditional PP.

Furthermore, advances in manufacturing techniques, such as 3D printing with PP materials, could expand the applications of PP rigid sheets even further. This evolution will likely lead to customized solutions that meet specific industry needs while enhancing performance characteristics.

Conclusion

In summary, PP rigid sheets play a vital role in various industries due to their lightweight nature, chemical resistance, impact resistance, thermal stability, and recyclability. Their diverse applications, from packaging to automotive components, highlight their versatility and the growing demand for environmentally friendly materials. As innovations continue to emerge, the role of PP rigid sheets is poised to expand, contributing to more sustainable practices and solutions in the future.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025