Feb . 18, 2025 11:31 Back to list

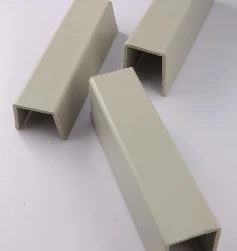

PP welding rod

In the evolving world of plumbing and infrastructure, PE pipe fittings have emerged as a vital component. Polyethylene (PE) pipes and their fittings offer unparalleled benefits that make them an ideal choice for modern construction and plumbing solutions. With years of expertise in materials engineering and an in-depth understanding of industry requirements, I am poised to delve into the unique advantages of PE pipe fittings, ensuring that stakeholders across the board can make informed decisions that enhance their operational efficiencies and cost-effectiveness.

The ease of installation that PE pipe fittings provide is another critical advantage. Due to their lightweight nature, handling and joining these fittings require less manpower and machinery compared to heavier alternatives. The use of electrofusion and butt-welding techniques allows for seamless connections, reducing installation time and the risk of joint-related failures. Contractors and engineers appreciate these properties as they shorten project timelines and reduce labor costs, while also ensuring leak-proof systems that stand the test of time. When discussing authority and trustworthiness, it is pertinent to highlight the standards and certifications that govern the use of PE pipe fittings in the industry. Organizations such as the American Water Works Association (AWWA) and the International Organization for Standardization (ISO) provide rigorous benchmarks that these fittings meet or surpass, ensuring that they are reliable for critical infrastructure projects worldwide. By adhering to such standards, manufacturers of PE fittings bolster the confidence of buyers and regulators alike, knowing they are investing in proven, high-quality solutions. In practical applications, PE pipe fittings have transformed sectors ranging from agriculture to urban utilities. In irrigation systems, their ability to resist scaling and biological growth ensures consistent water flow and maximized crop yields. In city water supply networks, their non-toxic and inert nature ensures public health is safeguarded while minimizing water loss. Industrial facilities use PE fittings for efficient, low-maintenance systems that can handle a wide range of chemicals and gases safely. In conclusion, polyethylene pipe fittings represent an advanced, expert-endorsed choice for today’s demanding infrastructure demands. With their blend of durability, environmental compatibility, ease of installation, and adherence to international standards, these fittings offer a trustworthy foundation for projects that require both performance and sustainability. Stakeholders who integrate PE pipe fittings into their operations not only gain an edge in efficiency but also contribute positively to the global pursuit of sustainable development practices.

The ease of installation that PE pipe fittings provide is another critical advantage. Due to their lightweight nature, handling and joining these fittings require less manpower and machinery compared to heavier alternatives. The use of electrofusion and butt-welding techniques allows for seamless connections, reducing installation time and the risk of joint-related failures. Contractors and engineers appreciate these properties as they shorten project timelines and reduce labor costs, while also ensuring leak-proof systems that stand the test of time. When discussing authority and trustworthiness, it is pertinent to highlight the standards and certifications that govern the use of PE pipe fittings in the industry. Organizations such as the American Water Works Association (AWWA) and the International Organization for Standardization (ISO) provide rigorous benchmarks that these fittings meet or surpass, ensuring that they are reliable for critical infrastructure projects worldwide. By adhering to such standards, manufacturers of PE fittings bolster the confidence of buyers and regulators alike, knowing they are investing in proven, high-quality solutions. In practical applications, PE pipe fittings have transformed sectors ranging from agriculture to urban utilities. In irrigation systems, their ability to resist scaling and biological growth ensures consistent water flow and maximized crop yields. In city water supply networks, their non-toxic and inert nature ensures public health is safeguarded while minimizing water loss. Industrial facilities use PE fittings for efficient, low-maintenance systems that can handle a wide range of chemicals and gases safely. In conclusion, polyethylene pipe fittings represent an advanced, expert-endorsed choice for today’s demanding infrastructure demands. With their blend of durability, environmental compatibility, ease of installation, and adherence to international standards, these fittings offer a trustworthy foundation for projects that require both performance and sustainability. Stakeholders who integrate PE pipe fittings into their operations not only gain an edge in efficiency but also contribute positively to the global pursuit of sustainable development practices.

Share:

Latest news

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025