Դկտ . 25, 2024 08:58 Back to list

hdpe reinforced spiral corrugated pipe

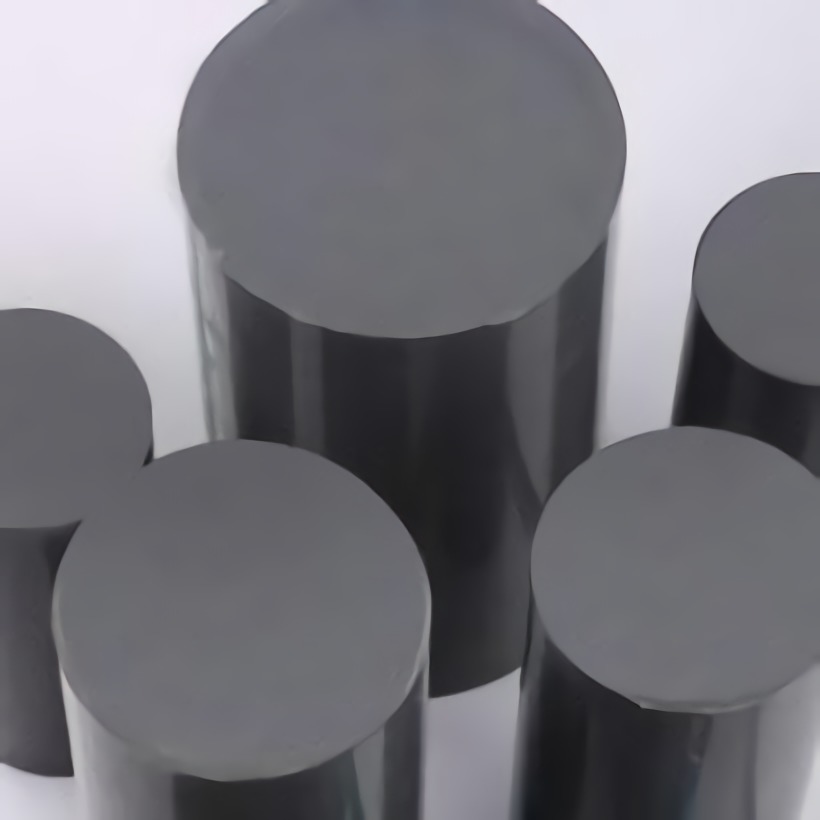

HDPE Reinforced Spiral Corrugated Pipe A Comprehensive Overview

In the realm of modern construction and infrastructure, the utilization of innovative materials has proven essential for ensuring durability, efficiency, and sustainability. One such advancement is the HDPE reinforced spiral corrugated pipe, a product increasingly favored in various applications, from drainage systems to industrial transportation. This article delves into the attributes, advantages, and applications of HDPE reinforced spiral corrugated pipes, showcasing their significance in today’s engineering landscape.

Understanding HDPE and Its Properties

High-Density Polyethylene (HDPE) is a thermoplastic polymer known for its high strength-to-density ratio. Renowned for its robustness, chemical resistance, and low moisture absorption, HDPE is an ideal material for pipe manufacturing. Its properties make it suitable for transporting water, chemicals, and gases without compromising integrity. When reinforced using a spiral corrugation technique, HDPE pipes gain additional strength and flexibility, allowing them to withstand external pressure and variable environmental conditions.

The Spiral Corrugated Design

The spiral corrugated design is characterized by the alternating inward and outward curves along the length of the pipe. This unique structure provides several advantages over traditional pipe designs. The reinforcement achieved through this spiral configuration enhances the pipe's load-bearing capacity while maintaining a lightweight profile. Moreover, the increased surface area contributes to better structural integrity, reducing the risk of collapse under heavy loads or during shifting soil conditions.

Advantages of HDPE Reinforced Spiral Corrugated Pipes

1. Strength and Flexibility One of the most notable benefits of these pipes is their superior strength combined with flexibility. This property makes them well-suited for various applications, from stormwater management to sewage systems, where ground movement can pose a risk to standard piping systems.

2. Corrosion Resistance Unlike traditional metal pipes that are prone to corrosion and rust, HDPE is chemically resistant, ensuring a longer lifespan with minimal maintenance. This characteristic makes them preferable in environments where they might be exposed to aggressive chemicals or natural elements.

3. Lightweight and Easy Installation The lightweight nature of HDPE reinforced spiral corrugated pipes allows for easier handling and installation compared to heavier alternatives. This can significantly reduce labor costs and construction time, making them an economical choice for large-scale projects.

hdpe reinforced spiral corrugated pipe

4. Cost-Effective Solutions While the initial investment in HDPE pipes may vary, their longevity and low maintenance needs often result in lower lifecycle costs. The combination of durability and efficiency contributes to a reduction in overall project expenses.

5. Environmental Impact Using HDPE contributes to sustainable development. It is recyclable and minimizes the ecological footprint compared to traditional materials. Additionally, the reduced need for maintenance and replacement further enhances its environmental credentials.

Applications

HDPE reinforced spiral corrugated pipes find utility across various sectors. Common applications include

- Stormwater Management These pipes facilitate efficient drainage systems, allowing for effective stormwater management without the risk of clogging or corrosion.

- Sewage and Wastewater Systems The strong and flexible nature of HDPE makes it ideal for sewage transport, accommodating fluctuating soil conditions and heavy loads with ease.

- Agricultural Irrigation In agriculture, these pipes are used for efficient irrigation systems, ensuring water is delivered sustainably and effectively to crops.

- Industrial Uses Many industries rely on HDPE reinforced spiral corrugated pipes for chemical transport and other applications where durability and resistance to harsh conditions are paramount.

Conclusion

In conclusion, HDPE reinforced spiral corrugated pipes represent a significant advancement in piping technology, offering unique benefits that cater to a wide array of applications. Their strength, flexibility, and durability make them a reliable choice for construction and industrial projects. As infrastructure requirements evolve and the demand for sustainable solutions increases, the relevance and application of HDPE reinforced spiral corrugated pipes are poised to grow, solidifying their status as a key player in modern engineering. Embracing these innovative materials is not merely a trend but a step toward a more sustainable and efficient future.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025