Aug . 26, 2025 17:36 Retounen nan lis la

Transform Your Projects with Premium Hdpe Plastic Sheets

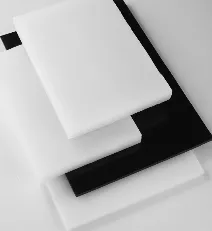

Plastic materials have revolutionized countless industries, but few offer the versatility, durability, and eco-friendly benefits of HDPE plastic sheets. Known for their toughness and resistance to impact, chemicals, and moisture, these sheets are the backbone of applications ranging from construction to packaging. Investing in quality HDPE plastic sheets ensures not only superior performance but also long-term savings due to their low maintenance and longevity. Whether you need sturdy barriers, durable liners, or reliable structural components, HDPE sheets stand out as a smart solution for modern demands.

Explore the Versatility of Hdpe Sheets 4x8 in Various Applications

Among the many formats available, the Hdpe sheets 4x8 size is especially popular for its balance between manageability and coverage area. This dimension fits seamlessly into standard fabrication processes, making it an ideal choice for fabricators, designers, and builders who require a reliable plastic sheet with a consistent footprint. The adaptability of Hdpe sheets 4x8 means they can be cut, shaped, and thermoformed into custom components, protective panels, or industrial parts without compromising strength. Their resistance to UV rays and moisture also makes these sheets a preferred option for outdoor projects that demand both durability and flexibility.

Benefits of Using Black Hdpe Sheet for Enhanced Performance

When appearance and extra durability are concerns, the black Hdpe sheet offers unique advantages. Its carbon black pigmentation not only provides UV stabilization but also enhances impact resistance, making it suitable for harsher environments where fading or cracking would normally occur. The deep color also adds a sleek aesthetic to finished products, making it an excellent choice for visible surfaces or protective coverings that must maintain a clean, professional look over time. Furthermore, the black Hdpe sheet is often favored in applications such as outdoor signage, marine dock components, and agricultural equipment due to its robust nature.

How Recycled Hdpe Sheets Contribute to Sustainable Manufacturing

In today’s world, sustainability is a critical factor when selecting materials. Using recycled Hdpe sheets aligns environmental responsibility with industrial needs, offering a green alternative that does not sacrifice quality. These sheets are manufactured from post-consumer or post-industrial HDPE waste, carefully processed to retain the material’s original strength and performance. Companies that adopt recycled Hdpe sheets demonstrate a commitment to reducing plastic waste and lowering carbon footprints. Their application ranges from packaging to construction panels, where durability combined with eco-friendliness adds substantial value.

Understanding the Importance of Hdpe Sheet Thickness in Project Success

Thickness plays a pivotal role in determining the functionality and strength of HDPE sheets, and choosing the correct Hdpe sheet thickness can make or break a project. Thicker sheets provide enhanced rigidity and resistance to bending or impact, making them suitable for load-bearing or protective applications. Conversely, thinner sheets offer greater flexibility and ease of fabrication, ideal for lining, wrapping, or lightweight covers. Manufacturers produce Hdpe sheets in a variety of thicknesses to suit diverse industrial requirements, ensuring that the final product matches the demands of its intended use without excess material or cost.

Selecting the Right Hdpe Plastic Sheets for Industrial and Commercial Use

The choice of Hdpe plastic sheets requires careful consideration of factors like chemical exposure, environmental conditions, and mechanical stress. Unlike other plastics, HDPE offers superior chemical resistance, making it ideal for tanks, liners, and surfaces exposed to acids, bases, or solvents. It’s also known for its low moisture absorption, meaning that even in wet or humid conditions, the sheets maintain their integrity. With options available in various sizes, colors, and thicknesses, selecting Hdpe plastic sheets tailored to your exact project ensures efficiency and durability, ultimately reducing maintenance needs and downtime.

Applications and Advantages of Hdpe Sheets 4x8 in Modern Fabrication

Fabricators appreciate Hdpe sheets 4x8 for their convenient size that fits standard machinery and fabrication workflows. This sheet size lends itself well to CNC cutting, thermoforming, and welding, allowing complex shapes and components to be produced with high precision. The material’s natural resistance to abrasion and corrosion extends the lifespan of fabricated parts, especially in industrial settings such as conveyor components, protective guards, and food processing equipment. The versatility and consistent quality of Hdpe sheets 4x8 make them indispensable for manufacturers striving to deliver high-performance products on time and within budget.

The Durability and Protection Offered by Black Hdpe Sheet in Harsh Conditions

When projects require material that can withstand extreme weather, impact, or UV exposure, the black Hdpe sheet shines as a superior solution. Its formulation with carbon black pigment acts as a shield against sunlight degradation, preventing brittleness and color loss over extended periods outdoors. This makes it the material of choice for applications like outdoor furniture, playground equipment, and vehicle parts that must endure constant wear and tear. Additionally, the black Hdpe sheet's high tensile strength ensures that it can absorb shocks and resist cracks, providing lasting protection and performance in demanding environments.

Hdpe Plastic Sheets FAQs

What are the primary advantages of using HDPE plastic sheets?

HDPE plastic sheets offer excellent impact resistance, chemical stability, moisture resistance, and versatility in fabrication, making them suitable for a wide range of industrial and commercial applications.

How does the size of Hdpe sheets 4x8 affect project planning?

The 4x8 feet size is a standard dimension that fits well into fabrication processes, balancing manageability with surface area coverage, which simplifies cutting and shaping while minimizing waste.

Are recycled Hdpe sheets as durable as virgin material?

Yes, recycled HDPE sheets maintain comparable strength and performance levels to virgin sheets due to advanced processing techniques, while offering environmental benefits.

Why is Hdpe sheet thickness important?

Thickness determines the sheet’s rigidity, load capacity, and flexibility; choosing the right thickness ensures the sheet can withstand specific stresses without unnecessary cost or weight.

Can black Hdpe sheets be used outdoors?

Absolutely. The carbon black pigmentation provides UV protection and enhanced durability, making black HDPE sheets ideal for prolonged outdoor exposure.

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NouvèlNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NouvèlNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NouvèlNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NouvèlNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NouvèlNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NouvèlNov.22,2025