Nov . 15, 2024 10:53 Back to list

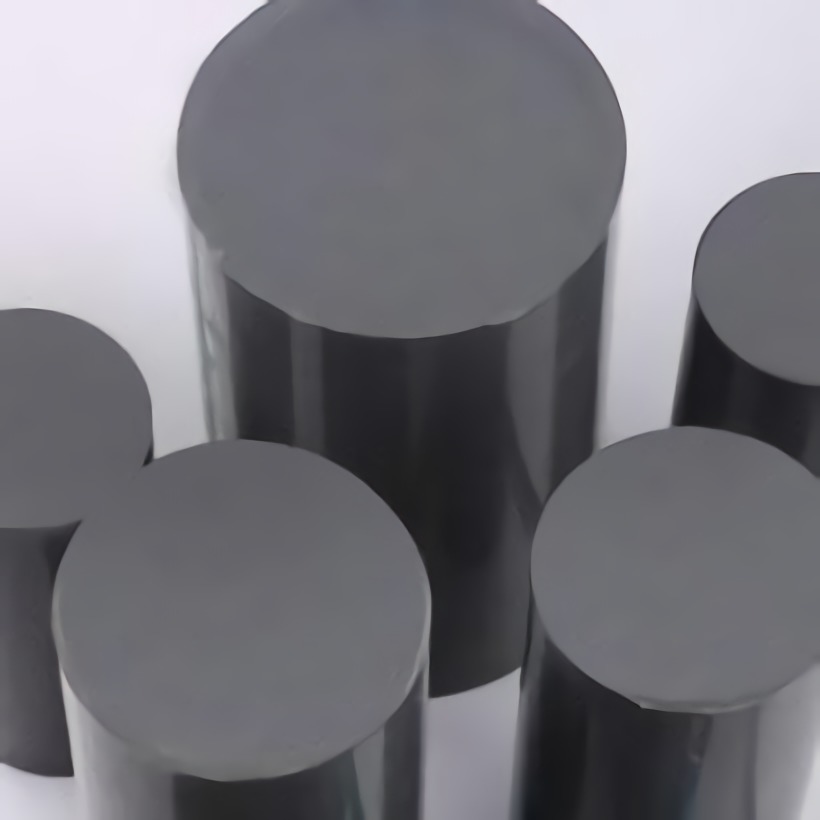

pp plate

The Significance of PP Plate in Modern Manufacturing

In the ever-evolving world of manufacturing, innovative materials play a vital role in enhancing production processes and product quality. One such material that has gained significant attention is Polypropylene (PP) plate, commonly referred to as PP plate. Widely used across various industries, the PP plate has garnered recognition for its versatility, durability, and eco-friendliness, making it an indispensable choice for manufacturers.

PP plates are made from polypropylene, a thermoplastic polymer known for its excellent chemical resistance and lightweight properties. This unique combination of attributes makes PP plates ideal for diverse applications, ranging from automotive parts to packaging materials and even medical equipment. Their ability to withstand rugged usage while maintaining structural integrity sets PP plates apart from many traditional materials, such as metal or wood.

The Significance of PP Plate in Modern Manufacturing

Moreover, PP plates are lightweight yet strong, offering an excellent alternative for industries aiming to reduce the weight of their products without compromising strength. In the automotive sector, for instance, the adoption of PP plates in manufacturing components contributes to overall vehicle weight reduction, resulting in improved fuel efficiency and lower emissions. With the global push for sustainability, the need for lightweight materials has become a significant focus for manufacturers looking to minimize their environmental impact.

pp plate

Another advantage of PP plates is their high resistance to UV degradation. This feature makes them suitable for outdoor applications, including signage, outdoor furniture, and agricultural equipment. Unlike other materials that can become brittle and lose color when exposed to sunlight, PP plates maintain their aesthetic appeal and functional properties, ensuring durability in outdoor settings.

In addition to their practical advantages, PP plates are also considered an eco-friendly choice. Polypropylene is a recyclable material, and many manufacturers are now implementing sustainable practices by recycling PP waste into new plates. This circular approach not only reduces landfill accumulation but also conserves natural resources, making PP plates a responsible option in a world increasingly focused on sustainability.

Furthermore, the customization potential of PP plates cannot be overlooked. Available in a variety of colors, thicknesses, and finishes, they can be tailored to meet specific design requirements, allowing manufacturers to create visually appealing products without sacrificing performance. This adaptability has made PP plates a favorite among designers and engineers alike, as they can seamlessly integrate into customized solutions across multiple industries.

As we move towards a more sustainable future, the importance of materials like PP plates cannot be overstated. Their unique combination of durability, chemical resistance, lightweight construction, and eco-friendliness positions them as a key player in the quest for innovative manufacturing solutions. Companies seeking to enhance their product offerings while simultaneously adhering to environmental guidelines will find PP plates to be an advantageous choice.

In conclusion, the rise of PP plates within the manufacturing sector underscores the ongoing quest for innovation and sustainability. With their myriad benefits and applications, these materials exemplify how the industry can adapt and evolve to meet the demands of modern consumers. As manufacturers continue to explore new possibilities, PP plates will undoubtedly play a significant role in shaping the future of manufacturing.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025