ruj . 22, 2024 14:01 Back to list

hdpe welding rod

Understanding HDPE Welding Rods An Essential Guide

High-Density Polyethylene (HDPE) is one of the most commonly used thermoplastics in various industries, thanks to its excellent chemical resistance, durability, and impact strength. One of the critical components in the joining and repair of HDPE products is the HDPE welding rod. This article explores the significance, application, and benefits of HDPE welding rods in plastic fabrication.

Understanding HDPE Welding Rods An Essential Guide

One of the primary advantages of using HDPE welding rods is their robust nature. Since they are produced from HDPE, the welds formed during the process exhibit similar properties to the base material. This results in joints that are not only strong but also resistant to environmental factors, making them ideal for applications in outdoor settings or harsh industrial environments. Additionally, HDPE welding rods are often UV stabilized, providing further protection against sun exposure, which can lead to degradation in some plastic materials.

hdpe welding rod

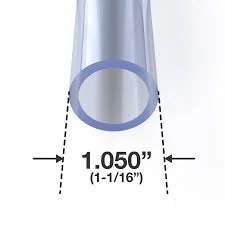

The application of HDPE welding rods varies widely. They are extensively used in industries such as agriculture, construction, and water management for repairs and fabrication of tanks, pipes, liners, and other products. For instance, in agricultural applications, HDPE pipes are vital for irrigation systems due to their resistance to corrosive chemicals and ability to withstand significant pressure. With the help of HDPE welding rods, leaks or damages can be quickly and effectively repaired, ensuring minimal downtime and loss.

Moreover, HDPE welding rods are environmentally friendly options as they are recyclable and promote sustainability. This is particularly important in today’s world, where industries are increasingly seeking sustainable materials and practices. By utilizing HDPE, which can be recycled, companies can reduce their carbon footprint and contribute to a circular economy.

In terms of installation and usability, HDPE welding rods are relatively easy to work with, making them a favored choice among welders and fabricators. Proper training and technique are essential to ensure efficient and effective welding. The key is maintaining the right temperature during the welding process to achieve a strong, cohesive bond without damaging the surrounding material.

In conclusion, HDPE welding rods play a pivotal role in the world of plastic fabrication. Their strong, compatible properties, versatility across various applications, and eco-friendly nature make them indispensable in industries where HDPE is utilized. As technology advances, the methods of using these rods continue to improve, making the welding process more efficient and sustainable. For anyone involved in HDPE fabrication or repairs, understanding and implementing HDPE welding rods can lead to significant benefits, both in quality and longevity of the materials used.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025