Nov . 13, 2024 09:30 Back to list

pvc plastic welding rod

Understanding PVC Plastic Welding Rods An Essential Guide

PVC plastic welding rods are indispensable tools in various industries, particularly in construction, plumbing, and manufacturing, where plastic components require maintenance or bonding. These rods are a form of filler material used during the welding process of polyvinyl chloride (PVC) to join two or more PVC surfaces effectively. In this article, we will explore the properties, uses, benefits, and techniques associated with PVC plastic welding rods.

What is PVC?

Polyvinyl chloride, commonly known as PVC, is a versatile thermoplastic polymer used widely in construction products such as pipes, doors, windows, and various consumer goods. Its durability, chemical resistance, and low cost make it a popular choice in many applications. However, over time, the integrity of PVC products can be compromised due to wear and tear, environmental factors, or accidental damages. This is where PVC plastic welding rods come into play.

Properties of PVC Welding Rods

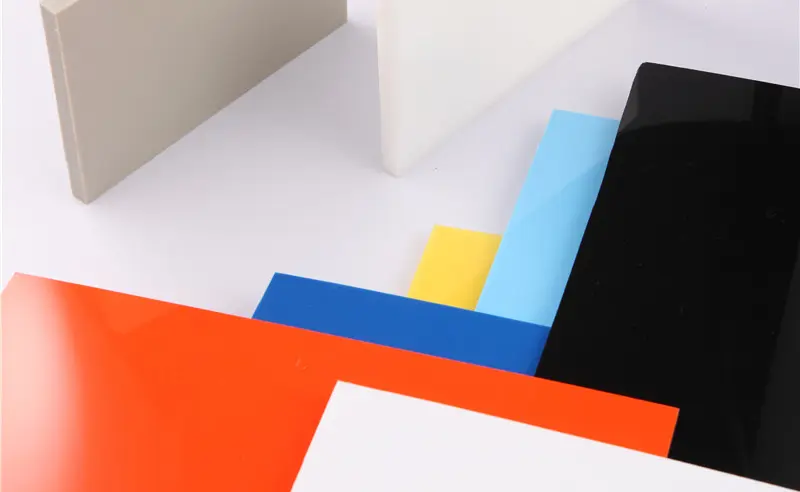

PVC welding rods are typically manufactured from the same material as the PVC surfaces they aim to bond. This ensures compatibility and optimal fusion during the welding process. The rods come in various diameters and lengths, allowing for flexibility in different welding applications. Crucially, they maintain the characteristics of PVC, such as resistance to UV light, impact, and chemicals.

One of the notable advantages of PVC welding rods is their ability to withstand high temperatures without deforming. This property is essential, as the welding process often involves elevated temperatures for the effective melting and bonding of PVC materials.

Applications of PVC Plastic Welding Rods

The applications for PVC plastic welding rods are vast. In plumbing, they are used to repair or connect PVC pipes that may have sustained damage. In construction, they can be employed to join panels or sheets made from PVC, ensuring a solid and leak-proof seal. Moreover, these rods are also used in fabricating custom PVC products, such as signage and display structures.

pvc plastic welding rod

In the manufacturing sector, PVC welding rods enable the assembly of various plastic components, enhancing production efficiency and product durability. The rods are also useful in automotive applications, particularly in repairs of plastic components and interiors.

Benefits of Using PVC Welding Rods

One of the primary benefits of using PVC welding rods is the ease of repair they offer. Rather than replacing an entire PVC component, which can be both costly and time-consuming, welding rods allow for quick repairs and restorations. This not only saves money but also contributes to sustainable practices by minimizing waste.

Additionally, welding with PVC rods creates a bond that is as strong, if not stronger, than the original material. This strength is crucial for applications that require structural integrity and reliability. The process is also relatively straightforward, making it accessible for individuals and businesses with varying levels of expertise in plastic welding.

Techniques for Welding with PVC Rods

The welding process generally involves heating the PVC surfaces and the welding rod until they reach the melting point. This can be achieved using various tools, including hot air welders, extrusion welders, or even lighter tools for smaller applications. The melted materials are then allowed to fuse together, creating a solid bond once cooled.

Before beginning the welding process, it’s important to clean the surfaces thoroughly to remove any dirt or grease, as this can affect the quality of the weld. It is also advisable to practice on scrap pieces of PVC to ensure proficiency before tackling the actual project.

Conclusion

PVC plastic welding rods are essential tools that facilitate the repair and assembly of PVC products across numerous industries. Their compatibility, durability, and ease of use make them a preferred choice for welders and DIY enthusiasts alike. By understanding their properties, applications, and the techniques involved in their use, workers can extend the lifespan of PVC materials and enhance their project outcomes. Whether for small repairs or large-scale constructions, PVC welding rods prove to be an invaluable asset in the plastic welding landscape.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025