Feb . 15, 2025 22:07 Back to list

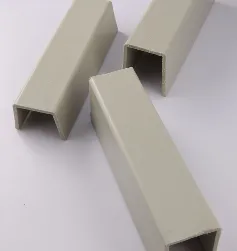

hdpe sheet cost

High-Density Polyethylene (HDPE) sheets represent an essential material choice across a multitude of industries. Understanding the cost structure of HDPE sheets is vital for businesses aiming to make informed purchasing decisions. The pricing of HDPE sheets hinges on several critical factors, each dictating the overall expenditure and long-term value derived from the product.

Market demand and supply dynamics continually alter HDPE sheet pricing. Economic conditions, raw material availability, and global supply chain situations can cause fluctuations. Firms must stay abreast of market trends, understanding these variables to time purchases advantageously and secure the best rates, especially during periods of market volatility. Moreover, the reputation and reliability of the supplier play a crucial role in HDPE sheet costs. Trustworthy suppliers often offer value-added services such as quality assurance, prompt delivery, and customer support, which may command a premium but ensure consistent product performance and peace of mind. Evaluating supplier credentials, certifications, and customer feedback enhances purchasing decisions and allocation of budget resources. Technological advancements in production might affect pricing too. Innovations can lead to more efficient manufacturing processes, resulting in cost reductions that suppliers may pass on to customers. Engaging with industry developments aids businesses in leveraging new opportunities for cost savings while accessing cutting-edge HDPE sheet products. Ultimately, when considering the cost of HDPE sheets, a comprehensive approach that assesses material quality, thickness, dimensions, geographical implications, market factors, supplier reliability, and technological advancements forms the basis for making strategic procurement decisions. Businesses should prioritize aligning their needs with these parameters, ensuring they not only manage costs effectively but also maximize the functional and financial returns on their HDPE sheet investments. This strategic insight empowers enterprises to confidently select HDPE sheets tailored to their precise requirements, backed by an understanding of cost influences driving market dynamics.

Market demand and supply dynamics continually alter HDPE sheet pricing. Economic conditions, raw material availability, and global supply chain situations can cause fluctuations. Firms must stay abreast of market trends, understanding these variables to time purchases advantageously and secure the best rates, especially during periods of market volatility. Moreover, the reputation and reliability of the supplier play a crucial role in HDPE sheet costs. Trustworthy suppliers often offer value-added services such as quality assurance, prompt delivery, and customer support, which may command a premium but ensure consistent product performance and peace of mind. Evaluating supplier credentials, certifications, and customer feedback enhances purchasing decisions and allocation of budget resources. Technological advancements in production might affect pricing too. Innovations can lead to more efficient manufacturing processes, resulting in cost reductions that suppliers may pass on to customers. Engaging with industry developments aids businesses in leveraging new opportunities for cost savings while accessing cutting-edge HDPE sheet products. Ultimately, when considering the cost of HDPE sheets, a comprehensive approach that assesses material quality, thickness, dimensions, geographical implications, market factors, supplier reliability, and technological advancements forms the basis for making strategic procurement decisions. Businesses should prioritize aligning their needs with these parameters, ensuring they not only manage costs effectively but also maximize the functional and financial returns on their HDPE sheet investments. This strategic insight empowers enterprises to confidently select HDPE sheets tailored to their precise requirements, backed by an understanding of cost influences driving market dynamics.

Share:

Next:

Latest news

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025